Links:

One of the key advantages of float glass manufacturing is its efficiency. In a typical float glass factory, the entire production process is highly automated. From the melting of raw materials—which typically includes silica sand, soda ash, and limestone—to the cutting, annealing, and packaging of finished glass sheets, modern technology ensures high precision and minimal waste. This automation not only speeds up the production cycle but also significantly reduces labor costs while maintaining product quality.

In contemporary interior design, bubble pattern glass is increasingly favored for its ability to add character and depth to spaces. Designers often use it as a statement piece, whether in lighting fixtures, wall art, or as accents in furniture. Its organic shapes and translucent qualities allow it to harmonize with various styles, from minimalist to bohemian.

This mirror is not just a practical tool for daily use; it doubles as a decorative element. Its slim silhouette can effortlessly blend into various interior styles, from contemporary to classic. It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner

It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner

It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner It can grace a dressing table, hang on a bathroom wall, or even serve as a stylish addition to a living room corner silver slim mirror. Its reflective surface can visually expand a space, creating an illusion of spaciousness, especially in smaller rooms. The process of manufacturing beveled low-e glass involves several steps. First, the glass is cut and ground to the desired shape and size. Then, the edges are carefully sloped or beveled using a grinding wheel or another specialized tool. Once the glass has been shaped, it undergoes a chemical treatment to strengthen it and make it more resistant to breakage. Finally, the low-emissivity coating is applied to one surface of the glass, either during the manufacturing process or as a separate step. In the realm of home decor and design, frosted pink glass has emerged as a versatile and timeless element that adds a touch of elegance and femininity to any space. This delicate material, with its soft, shimmering finish, has captivated designers and homeowners alike, offering a unique combination of privacy and style. The patterns on pattern glass can vary widely, ranging from delicate floral motifs to bold geometric shapes. Each pattern tells a unique story, often influenced by the cultural and societal trends of its time. For instance, the Victorian era was characterized by ornate, elaborate designs, while the Art Deco period favored sleek, symmetrical lines and abstract forms.

silver slim mirror. Its reflective surface can visually expand a space, creating an illusion of spaciousness, especially in smaller rooms. The process of manufacturing beveled low-e glass involves several steps. First, the glass is cut and ground to the desired shape and size. Then, the edges are carefully sloped or beveled using a grinding wheel or another specialized tool. Once the glass has been shaped, it undergoes a chemical treatment to strengthen it and make it more resistant to breakage. Finally, the low-emissivity coating is applied to one surface of the glass, either during the manufacturing process or as a separate step. In the realm of home decor and design, frosted pink glass has emerged as a versatile and timeless element that adds a touch of elegance and femininity to any space. This delicate material, with its soft, shimmering finish, has captivated designers and homeowners alike, offering a unique combination of privacy and style. The patterns on pattern glass can vary widely, ranging from delicate floral motifs to bold geometric shapes. Each pattern tells a unique story, often influenced by the cultural and societal trends of its time. For instance, the Victorian era was characterized by ornate, elaborate designs, while the Art Deco period favored sleek, symmetrical lines and abstract forms. Before delving into the slumping process, it's essential to understand what float glass is. Float glass is produced by pouring molten glass onto a bed of molten tin. This method results in a smooth, flat surface and uniform thickness, making it ideal for various applications, from windows to mirrors and decorative items. Its clarity and optical properties position float glass as a preferred choice in both commercial and residential settings.

When styling a room with an arch mirror silver, consider pairing it with other silver accents or metallic finishes to create a cohesive look. You can also mix and match different textures and materials to add interest and depth to the space. For a more minimalist look, keep the rest of the decor simple and let the mirror be the focal point of the room.

The Fascinating World of Bubble Pattern Glass

In the heart of a quaint village, nestled between the embrace of ancient oaks and the whisper of the river, stood a curious shop known as the Silver Wave Mirror. Its facade was unassuming, save for the large, silver-framed mirror that adorned the front window. This wasn't just any mirror; it was said to reflect not just one's image but also glimpses of their past and future. The Thin Mirror Glass The Art and Science of Float Glass Manufacturing The Louis Leaner Mirror, inspired by the opulent style of the French court, embodies the grace and elegance of the Louis era. Its silver finish, shimmering like moonlight on a serene lake, adds a touch of luxury to any room it graces. The mirror's reflective surface not only amplifies light and creates an illusion of spaciousness but also reflects the unique character of its surroundings, creating a captivating visual experience. The Silver Glam Mirror A Reflection of Elegance and Style The benefits of tempered glass are numerous. Its enhanced strength allows it to withstand high-impact forces, making it suitable for areas prone to physical abuse such as doors, windows, and shower enclosures. Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances

Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances

Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances Moreover, it has excellent thermal stability, capable of withstanding sudden temperature changes without cracking, which makes it an ideal choice for cooktops, oven doors, and other kitchen appliances tempered glass pdf. In conclusion, tempered acid etched glass is more than just a material; it's a design statement. Its combination of strength, aesthetics, and functionality makes it a sought-after element in contemporary architecture and interior design. It offers a perfect balance between form and function, seamlessly integrating style and safety into our living spaces. As technology advances, we can expect even more innovative applications of this remarkable material, further pushing the boundaries of design and functionality. In addition to adding decorative elements, it's important to consider the practical aspects of your bathroom window. Make sure to choose window treatments that are moisture-resistant and easy to clean, as bathrooms can be humid environments. Consider installing a ventilation fan to help prevent mold and mildew growth around your window. For interior designers, frosted glass is a versatile medium that can be wielded to craft partitions, decorative panels, or even artistic installations

tempered glass pdf. In conclusion, tempered acid etched glass is more than just a material; it's a design statement. Its combination of strength, aesthetics, and functionality makes it a sought-after element in contemporary architecture and interior design. It offers a perfect balance between form and function, seamlessly integrating style and safety into our living spaces. As technology advances, we can expect even more innovative applications of this remarkable material, further pushing the boundaries of design and functionality. In addition to adding decorative elements, it's important to consider the practical aspects of your bathroom window. Make sure to choose window treatments that are moisture-resistant and easy to clean, as bathrooms can be humid environments. Consider installing a ventilation fan to help prevent mold and mildew growth around your window. For interior designers, frosted glass is a versatile medium that can be wielded to craft partitions, decorative panels, or even artistic installations buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes. In the winter months, Low-E glass works in the opposite way. It allows more sunlight to pass through the window and into the building, which helps to warm the interior. At the same time, it reduces the loss of heat through the window by reflecting the infrared radiation back inside. This results in warmer indoor temperatures and reduced heating costs. Moreover, wave pattern glass is not limited to interior design alone In addition to these practical benefits, these units contribute to improved UV protection Silver mirror manufacturers must possess a deep understanding of materials science, optics, and metallurgy to achieve consistent results in their creations

buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes. In the winter months, Low-E glass works in the opposite way. It allows more sunlight to pass through the window and into the building, which helps to warm the interior. At the same time, it reduces the loss of heat through the window by reflecting the infrared radiation back inside. This results in warmer indoor temperatures and reduced heating costs. Moreover, wave pattern glass is not limited to interior design alone In addition to these practical benefits, these units contribute to improved UV protection Silver mirror manufacturers must possess a deep understanding of materials science, optics, and metallurgy to achieve consistent results in their creations In architecture, float glass is extensively used for windows, doors, and glass walls, providing excellent light transmission and thermal insulation Frosted glass, also known as etched or textured glass, is created by applying a special chemical solution or sandblasting process to the surface of clear glass. This treatment causes the glass to become slightly opaque, creating a frosted or matte finish. The resulting effect is a soft, diffused light that filters through the glass, casting a gentle glow and providing privacy without blocking out the view completely.

In architecture, float glass is extensively used for windows, doors, and glass walls, providing excellent light transmission and thermal insulation Frosted glass, also known as etched or textured glass, is created by applying a special chemical solution or sandblasting process to the surface of clear glass. This treatment causes the glass to become slightly opaque, creating a frosted or matte finish. The resulting effect is a soft, diffused light that filters through the glass, casting a gentle glow and providing privacy without blocking out the view completely. Transparent float glass is produced through a meticulous process that involves the floating of molten glass on a bed of molten tin. This method yields glass that is not only optically clear but also possesses a smooth surface and uniform thickness. The term float refers to the way the glass floats on the tin, allowing for a flat, distortion-free surface. The high quality of transparent float glass is a result of its composition, which typically includes silica sand, soda ash, and limestone. Various additives can be introduced to enhance specific properties, such as UV resistance or thermal insulation.

Exploring the Diversity of Glass Types Another significant benefit of annealed float glass is its affordability. Compared to other types of glass, such as tempered or laminated glass, annealed float glass is more cost-effective to produce. This makes it an ideal choice for projects with budget constraints or large-scale applications where cost is a significant factor. When considering the cost of mirror glass per square foot, it is important to also factor in any additional costs such as installation or delivery fees. Depending on the size and weight of the mirrors being purchased, these additional costs can quickly add up and should be taken into account when budgeting for new mirrors. In the field of interior decoration, aluminum mirror sheet is often used to create decorative elements such as wall panels, furniture, and lighting fixtures. The reflective surface of the sheet can help to brighten and visually enlarge a space, making it a popular choice for designers and architects. Moreover, the floating installation technique used for these glass panels enhances the perception of space

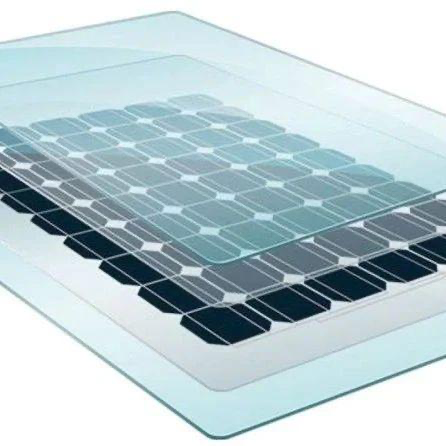

Float glass is made by floating molten glass on a bed of molten tin, creating a smooth, flat surface that is ideal for various applications. The 4mm thickness provides several advantages

The intricate designs and patterns found on silver traditional mirrors are a reflection of the rich cultural heritage and history of the craftsmen who create them. Each mirror is carefully handcrafted using traditional techniques that have been passed down through generations, ensuring that every piece is unique and of the highest quality. And so, the legend of the silver mantle and the mirror continued to captivate hearts and minds, inspiring generations with the promise of magic, wonder, and self-discovery. For within every soul lies the potential for greatness, waiting to be unlocked by a leap of faith and a touch of the extraordinary. The Luminous Allure of Reflectorized Glass One of the most popular types of patterned glass is stained glass, which is made by adding colored pigments to the glass during the manufacturing process

types of patterned glass. Stained glass is known for its vibrant colors and intricate designs, and it is often used in churches, museums, and historic buildings to create stunning windows and decorative accents. Stained glass can also be used in modern architecture to add a pop of color and create a focal point in a space. Privacy is another key benefit offered by tinted glass

tinted glass material. The degree of transparency can be adjusted according to need, allowing for a balance between visibility and seclusion. In residential settings, this can be particularly useful for bedrooms or bathrooms, while in commercial spaces, it can create a professional ambiance without compromising on light.

tinted glass material. The degree of transparency can be adjusted according to need, allowing for a balance between visibility and seclusion. In residential settings, this can be particularly useful for bedrooms or bathrooms, while in commercial spaces, it can create a professional ambiance without compromising on light. Frosted Glass, on the other hand, offers a level of privacy while still allowing light to pass through. It is created by etching or sandblasting the surface of the glass, giving it a translucent, matte finish. Frosted glass is commonly used in bathrooms, offices, and other areas where privacy is desired. In the world of modern architecture and interior design, the significance of materials that offer both aesthetic appeal and functional benefits cannot be overstated. One such material that has increasingly gained popularity in recent years is low e soft coat glass. This innovative type of glass combines a delicate balance of form and function, making it an ideal choice for a variety of applications. In conclusion, the silver mirror over the fireplace is not just a functional object but a symbolic representation of life's moments. It's a silent witness to the ebbs and flows of emotions, a beacon of warmth, and a reservoir of memories. It stands there, day after day, year after year, reflecting not only the physical surroundings but also the intangible essence of love, laughter, and life that fills the home. The silver mirror over the fireplace is indeed a living art piece, eternally capturing the heartbeat of the house. In conclusion, reflective privacy glass represents a significant advancement in the field of architectural design and interior decoration. Its unique combination of privacy, light control, energy efficiency, and aesthetic appeal makes it a valuable asset for anyone looking to enhance their living or working environment. As technology continues to evolve, we can expect further innovations in this area, leading to even more sophisticated solutions for our ever-changing needs. Overall, solar control low e glass is a cost-effective and sustainable solution for improving the energy efficiency and comfort of any building. Whether you are building a new home or looking to upgrade the windows in your current building, investing in solar control low e glass can help you save money on energy bills, reduce your environmental impact, and create a more enjoyable living or working environment. In the realm of architectural design and construction, one material that stands out for its versatility and aesthetic appeal is 3mm float glass. This thin yet robust glass variant is a staple in numerous applications, from windows and doors to interior decor and art installations. The process of cutting this glass to exact dimensions underscores the precision and skill involved in glass fabrication.

Furthermore, glass art has found its place in galleries and exhibitions worldwide, where artists showcase their work to an increasingly appreciative audience. The fusion of glass with other materials—like metal and wood—has also gained traction, allowing for multidimensional installations that captivate viewers.

In conclusion, the cost of tempered glass is not merely monetary but is measured in the peace of mind and assurance it provides. As an investment in safety and longevity, it proves to be an economical choice despite its initially higher price tag. Whether safeguarding a home or protecting vehicle occupants, tempered glass stands as a testament to the adage that sometimes, the best things really do come at a price. 3. Thickness Thicker glass generally costs more than thinner glass due to increased material costs and the need for additional support during the manufacturing process. Pyrolytic Low-E glass, also known as hard coat Low-E glass, is manufactured through a unique process called pyrolysis. This involves applying a thin layer of metal oxide, usually tin or silver, onto the surface of the glass while it's still hot, typically at temperatures around 600°C. The result is a highly reflective, yet transparent, glass surface that offers exceptional thermal insulation properties.

How to identify whether it is natural crystal

(1) Eyes: Natural crystals in the formation process, often affected by the environment always contain some impurities, when observing the sun, you can see light uniform fine horizontal lines or catkins. And the fake crystal mostly uses the residual crystal ballast, glass ballast melting, after polishing processing, color imitation, there is no uniform stripe, catch-like material.

Furthermore, transparent float glass finds its place in the manufacturing of various consumer products. It is used in displays, glass furniture, mirrors, and even in the production of glass containers for food and beverages. The durability, ease of fabrication, and aesthetic appeal of float glass make it a preferred choice for designers and manufacturers alike.