Links:

Today, conveyor belts come in various forms, each designed to suit specific needs

. The most common types include1. Gummiriemen Diese Riemen bieten eine hohe Flexibilität und sind resistent gegen verschiedene Umwelteinflüsse.

In modern vehicles, fan belts are typically constructed from rubber compounds that are resistant to heat and wear. Regular maintenance checks are critical because a worn fan belt can lead to engine overheating and a decrease in electrical charging, affecting overall vehicle performance. Symptoms of a failing fan belt may include unusual noises, a warning light on the dashboard, or accessories not functioning properly.

- Zdravotnictví V nemocnicích se automatické pásy využívají k přepravě lékařských potřeb a vzorků, což zvyšuje efektivitu a bezpečnost zdravotnických služeb.

Applications Across Industries

4. Cleaning Keep the belt clean from debris and oil, which can degrade the rubber and affect performance.

A Legacy of Durability

4. Weight Efficiency Motorcycle chain belts are generally lighter than chains, which can enhance the overall performance of the motorcycle, particularly during acceleration.

Automotive parts play a crucial role in determining overall vehicle performance. High-quality components ensure that vehicles operate smoothly and efficiently. For instance, a well-functioning suspension system not only provides comfort to passengers but also enhances handling and stability at high speeds. Similarly, effective brake systems are vital for ensuring safety, reducing stopping distances and preventing accidents.

Ignoring the state of your serpentine belt can lead to significant issues down the line

. Here are some common signs that your serpentine belt may be failingIn the realm of mechanical engineering, the components that facilitate effective machinery operation are essential. One such component is the poly V belt, known for its performance, versatility, and efficiency. Among the various types of poly V belts, the 135J6 variant stands out due to its unique design and application capabilities. This article aims to delve into the intricacies of the 135J6 poly V belt, examining its features, applications, and advantages.

The Myvi 1.5, a popular model amongst Malaysian drivers, relies on its V-belt for optimal operation of key engine components. In this model, the V-belt connects the crankshaft to various accessories. An effectively functioning V-belt leads to

The washing machine belt is a rubber or polyurethane strap that connects the motor to the drum of the washing machine. Its primary function is to transfer power from the motor to the drum, enabling it to rotate and agitate the clothes during washing and spinning cycles. Depending on the model of the washing machine, there can be different types of belts, including the drive belt, pump belt, and more.

Banded belts are designed for high-performance applications

. Their construction allows for increased flexibility, enabling them to navigate around pulleys and other components with ease. This flexibility not only contributes to smoother operation but also reduces vibrations and noise, creating a more pleasant working environment. Furthermore, banded belts can handle higher loads compared to traditional single belts, making them ideal for heavy machinery and equipment.banded belt

Moreover, a properly functioning timing belt maximizes fuel efficiency and optimizes engine performance. Regular maintenance of the timing belt can help avoid unexpected breakdowns and prolong the lifespan of your engine.

v drive belts

2. HVAC Systems Heating, ventilation, and air conditioning systems often rely on EPDM PK belts to drive fans and other components. The resistance to temperature fluctuations and ozone exposure contributes to the reliability of these systems.

4. Poly-V Belts These are multi-ribbed belts that offer a compact design and smooth operation. Poly-V belts provide high power transmission in a smaller space and are commonly used in automotive and industrial applications.

ဘယ်လ့်ပ် ဖိုလီ ဗီ ကီလင်ဒါ

The origins of conveyor belts can be traced back to the late 18th century. In 1795, the first conveyor belt was created for use in a flour mill. However, it wasn’t until the early 20th century that conveyor belts gained widespread popularity, especially in automotive assembly lines. Henry Ford famously incorporated them into his production processes, which significantly reduced the time it took to manufacture vehicles. This innovation not only revolutionized the automotive industry but also set a precedent for other sectors to adopt conveyor systems as a standard practice.

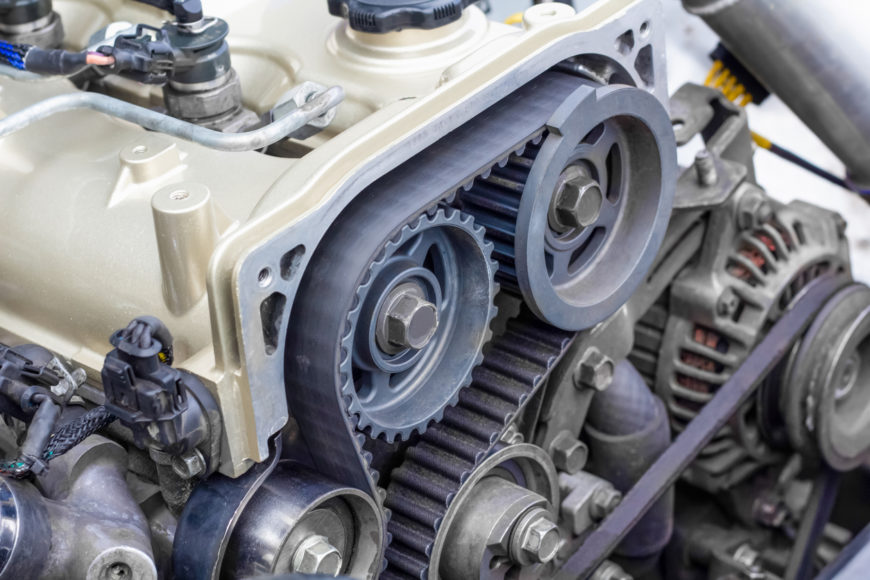

Understanding Timing Belt Operation The Heart of Your Engine

يعمل حزام V على نقل الحركة من المحرك إلى المكونات الأخرى عبر العجلات المسننة. عندما يدور المحرك، يتحرك حزام V بالتزامن مع ذلك، مما يدفع المكونات المرتبطة به. تعتمد فعالية هذا الحزام على عدة عوامل، بما في ذلك جودة الحزام، وضغطه، والزوايا التي يتم بها تثبيته.

Furthermore, the flexibility of Poly V belts allows for the use of smaller pulleys, which can lead to more compact designs in machinery. This is particularly beneficial in automotive applications, where saving space is often critical. The multi-rib design also minimizes the risk of belt slippage, ensuring smoother operation and longer service life.

Poly V belts, also known as serpentine belts or multiple V belts, are crucial components in various machinery and automotive applications. They are designed to transmit power efficiently across multiple pulleys, ensuring that engines and mechanical systems operate smoothly. This article delves into the types of poly V belts, their applications, and key features to consider before making a selection.

Replacement Process

How Does the Serpentine Belt Work?

Performance and Handling

honda civic hatchback for sale images

Understanding Ribbed Drive Belts A Key Component in Modern Machinery

Exploring the World of Used Vans A Comprehensive Guide

4. Flexibility and Elasticity EPDM offers a superior degree of flexibility and elasticity, allowing it to maintain a tight grip on pulleys and avoid slippage, resulting in more efficient power transfer.

fan belt 6 pk\/auto epdm fan belt

2. Noise Chains tend to be noisier than belts, which can detract from the overall riding experience, especially on longer journeys.

Key Components

2. Durability

The adaptability of SPV V-belts makes them ideal for various sectors. In the automotive industry, they are commonly found in alternators, water pumps, and air conditioning systems. In industrial settings, SPV V-belts are used in conveyor systems, compressors, and fans. Moreover, consumer appliances, such as washing machines and refrigerators, also benefit from the reliability of SPV V-belts.

The Rise of Technology

On the international front, many global players have expanded their presence in Thailand, either through partnerships, joint ventures, or establishing production facilities. Notable brands offer advanced technology and superior product quality, thus raising competition standards within the local market. This influx of international companies drives local manufacturers to continuously improve their production processes, invest in research and development, and adopt innovative technologies.

Importance of Timely Replacement

- Low Maintenance Unlike chain systems, timing belts do not require regular lubrication, making them easier and more cost-effective to maintain.

Synchronous belts, also known as timing belts, are an essential component in numerous machinery and automotive applications. They play a vital role in power transmission by synchronizing the rotation of shafts, ensuring that components like gears and pulleys turn in unison. As industries advance and demand for precision engineering increases, the importance of high-quality synchronous belts becomes paramount. If you’re in the market for synchronous belts, understanding their types, benefits, and where to purchase them can greatly influence your decision-making process.

Importance of Choosing the Right Size

The Rise of Technology

In the world of fitness, variable belts have also found a niche. Many athletes and fitness enthusiasts utilize adjustable belts as part of their workout gear. Whether for weightlifting or running, these belts provide the necessary support and comfort without the bulk of traditional counterparts. The adjustable feature allows for varying levels of tightness, catering to different exercises and body movements, which enhances performance and reduces the risk of injury.

Applications of Rubber V Belts

4. Better Resistance to Environmental Factors Double timing belts can also offer better resistance to environmental factors such as heat, oil, and fuel exposure. This resilience can prevent premature wear and tear, further enhancing the belt's longevity.

3. Чысціня Часавы ремень варта абараняць ад бруду і смецця. Регулярна праводзьце чыстку зоны, дзе размешчаны принтар, каб прадухіліць назапашванне часцінак, якія могуць паўплываць на яго працу.

1. Serpentine Belts Modern vehicles typically use serpentine belts, which are designed to drive multiple accessories from the engine's crankshaft. Priced between $25 to $75, serpentine belts are generally more affordable due to their mass production and widespread use. However, their quality can vary greatly, with premium options costing more and offering better durability.

Understanding 5PK 970

Like all components in a vehicle, timing belts have a finite lifespan and require regular maintenance. Most manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, depending on the vehicle's make and model. Neglecting this service can lead to severe consequences, including engine failure.

Evolving Trends

Key Features of B Series Timing Belts