Links:

HPMC for Detergent A Versatile Additive in Cleaning Formulations

Factors to Consider When Choosing HPMC Suppliers

1. Reputation and Reliability Established suppliers with a reputation for reliability typically have undergone rigorous testing and certification processes. They should have a track record of delivering consistent quality.

hpmc suppliers

The role of HPMC manufacturers extends beyond simply producing this essential polymer; they are also crucial in research and development. By focusing on the latest technologies and production methods, these manufacturers strive to enhance product performance, reduce environmental impact, and meet ever-evolving industry standards. Many manufacturers are committed to sustainability, implementing eco-friendly practices and exploring biodegradable options to minimize their carbon footprint.

6. Compatibility with Other Additives HPMC is compatible with a variety of other additives commonly used in gypsum formulations, such as retarders and anti-fungal agents. This compatibility allows for the customization of gypsum products to meet specific performance requirements.

In addition to the degree of substitution, the molecular weight of HPMC also plays a significant role in its solubility profile. Lower molecular weight derivatives tend to dissolve faster than their higher molecular weight counterparts. However, higher molecular weight HPMC offers greater viscosity, which can be beneficial in applications requiring thicker solutions. As such, formulators must balance the desired viscosity and the rate of solubility based on the intended application.

hpmc solubility in cold water

2. Production Technology Advances in production technology can also affect pricing. Manufacturers that adopt more efficient production methods can lower their operational costs, consequently offering HEC at competitive prices. Conversely, older production methods that are less efficient may lead to higher costs.

In addition to pharmaceuticals, HPMC is extensively utilized in the construction industry. It serves as a crucial additive in cementitious materials, providing improved workability and open time. Its water-retaining properties are vital for ensuring that mortar and plasters do not dry out too quickly, allowing for better adhesion and durability. This dual functionality of HPMC makes its manufacturers integral to both industries.

In conclusion, hydroxypropyl methylcellulose is a versatile polymer with vast applications across multiple industries. Its ability to function as a thickening agent, binder, emulsifier, and film former makes it an invaluable ingredient in pharmaceuticals, food, cosmetics, and construction. As consumer demand for sustainable and effective products continues to rise, HPMC will likely remain a key player in the formulation of innovative solutions that meet industry standards. Its unique properties ensure that it will continue to play a pivotal role in enhancing product performance and ensuring consumer satisfaction.

Properties of Hydroxyethylcellulose Powder

In the food industry, HPMC is utilized as a food additive, imparting desirable properties such as improved texture, moisture retention, and emulsification. HPMC suppliers play an essential role in ensuring that food manufacturers have access to food-grade products that comply with health and safety regulations. This aspect is vital, as consumers increasingly demand transparency and quality from food products.

hpmc supplier

In the construction industry, redispersible latex powders are widely used in cement and gypsum-based formulations. They improve the workability of adhesives and mortars, allowing for easier application and better performance. For tile adhesives, for instance, these powders provide improved adhesion to a variety of surfaces, including concrete, gypsum board, and ceramic tiles. They also contribute to the formulation's resistance to moisture, cracking, and shrinkage, thereby extending the longevity of constructions.

- Applications Utilized in dry mix products, as well as in pharmaceutical and food industries, especially in instant food preparations.

hpmc types

China has emerged as a global leader in the production of HPMC, tapping into the increasing demands for high-quality materials across diverse sectors. The surge in urbanization and infrastructure development has amplified the need for construction materials that enhance performance and sustainability. HPMC serves as a crucial additive in cementitious products, including mortars, tile adhesives, and plaster. Its ability to improve water retention, workability, and adhesion makes HPMC indispensable for modern construction practices.

Before discussing where to buy HEC, it’s essential to understand what it is and its applications. Cellosize hydroxyethyl cellulose is derived from cellulose, and its chemical modification allows it to dissolve in water, forming a clear and viscous solution. This property makes it ideal for thickening agents in paints, coatings, personal care products like lotions and creams, and even in food products where viscosity is desirable.

In the cosmetics sector, HPMC is utilized in various formulations, including creams, lotions, and gels. Its thickening and stabilizing characteristics help achieve the desired texture and consistency in personal care products. Additionally, HPMC contributes to the product’s application and moisture retention, enhancing user experience. As the demand for natural and organic cosmetic products grows, HPMC manufacturers continue to innovate, delivering high-quality, sustainable alternatives.

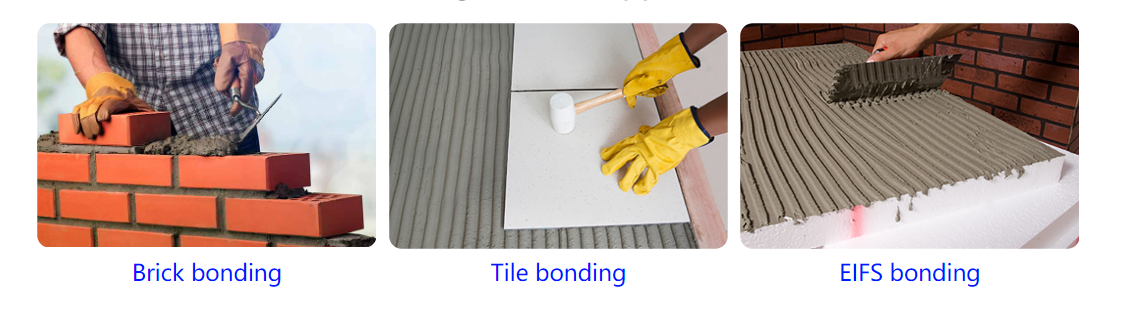

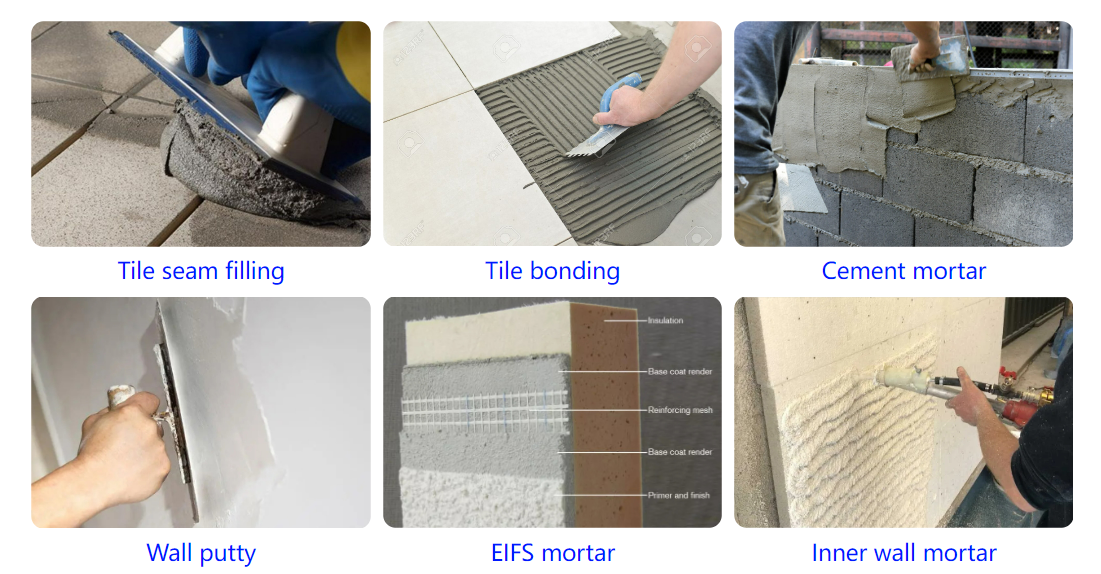

Construction and Building Materials

Hydroxyethylcellulose is a highly versatile polymer with a wide range of applications across various industries. Its thickening, gelling, and stabilizing properties make it an invaluable ingredient in many products, from cosmetics to pharmaceuticals and food items. With its growing market availability, sourcing hydroxyethylcellulose for sale has never been easier. As industries continue to demand high-quality ingredients, HEC remains a popular choice, proving its significance in both current and future applications. Whether for personal or commercial use, understanding the properties and purchasing considerations for hydroxyethylcellulose can lead to successful formulation and product development.

HPMC is known for its excellent film-forming properties, viscosity, and adhesive qualities, which make it an ideal candidate for use in thickening agents, emulsifiers, and binders. Unlike many other cellulose derivatives, HPMC is soluble in cold water, making it particularly versatile. The solubility of HPMC in cold water is influenced by several factors, including the degree of substitution, molecular weight, and temperature.

Methyl hydroxyethyl cellulose (MHEC) is a versatile cellulose derivative that has gained significant importance in various industries, including construction, pharmaceuticals, food production, and personal care. Its unique properties, such as water retention, thickening ability, and film-forming characteristics, make it a preferred choice for formulators and manufacturers across different sectors. This article explores the role of MHEC manufacturers, the applications of MHEC, and the industry dynamics.

In conclusion, the properties of Hydroxypropyl Methylcellulose (HPMC) offer a wide range of applications that address the needs of different industries. Its thickening, emulsifying, and film-forming capabilities make it a valuable component in pharmaceuticals, food products, personal care, and construction materials. With the continued trend towards sustainability, HPMC stands out as a safe and environmentally friendly option for manufacturers looking to innovate and meet consumer demands. As research and development in this area progress, the applications of HPMC are likely to expand, further cementing its role in various markets.

The purified HEC is then concentrated, often through evaporation, and subsequently dried. Common drying techniques include spray drying or freeze-drying, both of which aim to reduce the moisture content to a level suitable for storage and usability. The drying process is crucial, as excess moisture can lead to degradation of the product and affect its performance.

Density, defined as mass per unit volume, is a fundamental physical property that influences how substances behave in different environments. For HPMC, density plays a vital role in its application, particularly in formulations where consistency and stability are paramount. The density of HPMC can vary based on its degree of substitution (the ratio of hydroxypropyl and methyl groups attached to the cellulose backbone), molecular weight, and moisture content.

In dietary supplements, HPMC serves multiple purposes, from enhancing texture and consistency to improving bioavailability of active ingredients. Its solubility in hot and cold water allows it to be used effectively in various formulations, including powders, tablets, and capsules.

Conclusion

The MHEC manufacturing landscape is continuously evolving, with innovations in production technology and formulation strategies. Manufacturers are increasingly exploring ways to enhance the performance of MHEC, including modifications that improve its solubility, thermal stability, and compatibility with various solvents and additives.

Alkalization treatment: Place the pretreated cellulose into a reactor and add sodium hydroxide solution for alkalization treatment. This step aims to disrupt the crystal structure of cellulose, making it easier for subsequent etherification reactions.

The pH of the solution can also influence the solubility of HEC. Typically, HEC exhibits good solubility in neutral to slightly alkaline environments. Extreme pH levels, whether acidic or alkaline, can lead to hydrolysis of the polymer backbone or side groups, thus affecting its solubility and functionality.

In conclusion, HPMC is a vital ingredient across various sectors, and China's position as a leading supplier is leveraging the compound's adaptability to meet global demands. As industries evolve and prioritize quality and sustainability, the role of HPMC in enhancing product performance will undoubtedly expand, solidifying China's reputation in the global marketplace. Whether in pharmaceuticals, construction, food, or personal care, HPMC is set to remain a cornerstone of innovation and functionality, with Chinese suppliers at the forefront of this essential chemical industry's growth.

2. Stabilization Hydroxyethyl cellulose acts as a stabilizer in emulsions, helping to maintain the uniformity and texture of products. Its stabilizing properties prevent the separation of oil and water phases in creams and lotions, ensuring a consistent product over time.

Conclusion

Methyl hydroxyethyl cellulose (MHEC) is a non-ionic cellulose ether that has gained significant attention in various industries due to its versatile properties and applications. Derived from natural cellulose, MHEC is modified to enhance its performance characteristics, making it a crucial ingredient in many formulations, particularly in construction, pharmaceuticals, and food industries.

The adhesion properties of gypsum plaster are crucial for ensuring long-lasting performance in wall applications. HPMC enhances the adhesive capabilities of gypsum plaster by increasing its bond strength with substrates. This characteristic is particularly beneficial when applying plaster to challenging materials or surfaces that typically resist adhesion. The improved bond helps prevent peeling or flaking, making structures more durable and reliable over time.

Conclusion

Conclusion

For instance, by investing in green chemistry processes, some manufacturers have begun producing MHEC with reduced environmental impact, appealing to environmentally conscious consumers and companies. These advancements not only enhance the reputation of the manufacturers but also contribute to the overall sustainability of the industries they supply.

The incorporation of Hydroxypropyl methylcellulose (HPMC) into gypsum products represents a significant advancement in construction technology. By enhancing workability, prolonging open time, improving adhesion, and promoting sustainability, HPMC plays a crucial role in the development of high-performance gypsum formulations. As the construction industry continues to evolve, the synergy between HPMC and gypsum products will undoubtedly pave the way for innovative and efficient building solutions that meet the demands of modern construction practices.

1. Cosmetics and Personal Care In the beauty industry, HEC is commonly utilized as a thickener and stabilizer in products such as lotions, creams, gels, shampoos, and conditioners. Its ability to enhance the texture and consistency of formulations makes it a popular choice among cosmetic manufacturers. Additionally, HEC provides a smooth, luxurious feel when applied to the skin or hair.

1. Choose the Right Water Temperature HEC is more soluble in warm water than in cold. Start with water that is at least room temperature (around 20°C or 68°F), but not exceeding 80°C (176°F). Using hot water helps to hydrate the polymer more efficiently, making the dissolution process smoother.

HPMC is a non-ionic, water-soluble polymer derived from cellulose, which is a natural polymer found in the cell walls of plants. Its structure comprises a hydrophilic (water-attracting) portion and a hydrophobic (water-repelling) portion. This unique combination of properties allows HPMC to dissolve in cold water and form a viscous gel or thickening agent. The degree of substitution (the extent to which hydroxyl groups in cellulose are replaced by hydroxypropyl and methyl groups) can be tailored to achieve specific functional properties.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) is a popular non-ionic polymer widely used in various industries, including pharmaceuticals, food, and construction. One of the critical questions surrounding HPMC concerns its solubility in water. Understanding whether HPMC is water-soluble is fundamental for its application in different fields, as solubility impacts its functionality and effectiveness.

Several factors contribute to the pricing of hydroxyethyl cellulose per kilogram. These include raw material costs, production methods, geographical regions, and market demand.

Hydroxyethyl cellulose is a versatile and valuable ingredient across multiple industries, thanks to its unique properties and capabilities. Its uses range from improving the consistency of pharmaceuticals and cosmetics to enhancing the texture of food products. As industries continue to seek natural and effective solutions, HEC stands out as an exemplary polymer that combines functionality with safety, demonstrating its importance in modern formulations. With ongoing research and development, the potential applications of hydroxyethyl cellulose are likely to continue expanding, solidifying its place as a key ingredient in many formulations.

2. Thermal Stability HPMC is stable under a wide range of temperatures, making it suitable for processes that require heat.

Properties of HEC

F: Improve the workability of mortars