Current location:

Links:

-

In the realm of mechanical engineering, bearings are the unsung heroes that ensure smooth and efficient operation of various machines and systems. Among these, the 33895 bearing stands out for its exceptional performance and durability, setting a new benchmark in the industry. Furthermore, these bearings are known for their exceptional load capacity 3. Load Capacity The load capacity of a bearing refers to its ability to withstand external forces without failure. Bearings with higher load capacities are generally more expensive, as they require stronger materials and more complex designs to ensure durability.

- Proper Handling: When handling angular contact bearings, it's imUsing an angular contact bearing involves several key considerations to ensure proper installation and operation. In conclusion, the Hyatt cylindrical roller bearing catalog is a valuable resource for anyone in need of high-quality bearings for their equipment. With a wide range of options to choose from and a reputation for excellence, Hyatt bearings are the preferred choice for demanding applications where performance and reliability are paramount. Trust Hyatt to provide the bearings you need to keep your equipment running smoothly and efficiently. In automotive engines, for instance, these bearings are often found in the wheel hub assemblies, ensuring smooth rotations and minimizing wear. In industrial machinery, they are used in pumps, fans, and motors, reducing power consumption and enhancing operational reliability. They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount

In terms of design, double angular contact bearings are available in a variety of configurations to accommodate different mounting arrangements. Flanged outer rings, split inner rings, and integrated seals are just a few of the options available to optimize the bearing's performance in various applications. This flexibility makes double angular contact bearings a popular choice for a wide range of industries, including aerospace, automotive, and industrial machinery. The Unparalleled Performance of 32014 Bearing A Comprehensive Analysis Moreover, proper installation and maintenance of these bearings are equally important. Regular lubrication, cleaning, and timely replacement when signs of wear appear are necessary to maintain the bearing's efficiency and prevent premature failure. Both the LM11949 and LM11910 share a common thread of reliability and robustness

lm11949 lm11910. They are designed to withstand harsh operating conditions, with robust protection features like current limiting and thermal shutdown, ensuring safe operation and extended device life. Their compact package sizes also contribute to their popularity, allowing for easy integration into complex circuit designs without compromising on performance or space constraints. One of the key features of 33113x2 bearing is its ability to withstand heavy loads and high speeds. This makes it ideal for use in various types of machinery, such as gearboxes, motors, and pumps. Its robust construction and high-quality materials ensure that it can operate smoothly and efficiently under demanding conditions. 5. Static Load Rating 3,450 N The 6215 2RS bearing, a precision-engineered component integral to the operation of numerous mechanical systems, has undergone significant transformation since its inception. This bearing, characterized by its double rubber seals and contact with both rows of balls, offers superior performance in terms of load capacity, speed, and resistance to contaminants. One of the key features of the 6008 ball bearing is its ability to support both radial and axial loads. This makes it suitable for applications where the bearing will be subjected to varying types of forces. The deep groove design of the bearing also allows for high speeds and good performance in demanding conditions. Proper maintenance and care are essential for ensuring the longevity and optimal performance of the LM67010 bearing. Some key maintenance practices include

lm11949 lm11910. They are designed to withstand harsh operating conditions, with robust protection features like current limiting and thermal shutdown, ensuring safe operation and extended device life. Their compact package sizes also contribute to their popularity, allowing for easy integration into complex circuit designs without compromising on performance or space constraints. One of the key features of 33113x2 bearing is its ability to withstand heavy loads and high speeds. This makes it ideal for use in various types of machinery, such as gearboxes, motors, and pumps. Its robust construction and high-quality materials ensure that it can operate smoothly and efficiently under demanding conditions. 5. Static Load Rating 3,450 N The 6215 2RS bearing, a precision-engineered component integral to the operation of numerous mechanical systems, has undergone significant transformation since its inception. This bearing, characterized by its double rubber seals and contact with both rows of balls, offers superior performance in terms of load capacity, speed, and resistance to contaminants. One of the key features of the 6008 ball bearing is its ability to support both radial and axial loads. This makes it suitable for applications where the bearing will be subjected to varying types of forces. The deep groove design of the bearing also allows for high speeds and good performance in demanding conditions. Proper maintenance and care are essential for ensuring the longevity and optimal performance of the LM67010 bearing. Some key maintenance practices include  They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount

They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount They also find their way into high-speed applications like drones and robotics, where precision and durability are paramount 6205 ball bearing. The 6207 2RS is a deep groove ball bearing, a common type used in various industrial applications. The '6207' part of the code indicates the size of the bearing, referring to its inner diameter of 35mm and a standard width. The ' 2' signifies the series, which is a classification based on the bearing's dimensions and load-carrying capabilities. It is designed to handle both radial and axial loads, making it versatile for different applications. The pricing of 6004Z bearings is influenced by several key elements. Firstly, raw material costs, primarily steel, form a significant portion of the bearing's manufacturing expense. Fluctuations in global steel prices directly impact the bearing's final cost. Additionally, the quality of materials used, such as the type of lubricant or precision of the balls, can also affect the price. When selecting a taper roller bearing, it is important to consider factors such as load capacity, speed rating, and temperature range

6205 ball bearing. The 6207 2RS is a deep groove ball bearing, a common type used in various industrial applications. The '6207' part of the code indicates the size of the bearing, referring to its inner diameter of 35mm and a standard width. The ' 2' signifies the series, which is a classification based on the bearing's dimensions and load-carrying capabilities. It is designed to handle both radial and axial loads, making it versatile for different applications. The pricing of 6004Z bearings is influenced by several key elements. Firstly, raw material costs, primarily steel, form a significant portion of the bearing's manufacturing expense. Fluctuations in global steel prices directly impact the bearing's final cost. Additionally, the quality of materials used, such as the type of lubricant or precision of the balls, can also affect the price. When selecting a taper roller bearing, it is important to consider factors such as load capacity, speed rating, and temperature range

taper roller bearing catalogue. By choosing the right bearing for the application, you can ensure optimal performance and long service life.

In summary, the key difference between tapered roller bearings and ball bearings lies in their design and load-carrying capabilities. Tapered roller bearings are designed to support both radial and axial loads, while ball bearings are primarily intended for radial load support. Each type of bearing is tailored to meet specific operational requirements and environmental conditions in diverse industrial applications.

Furthermore, the installation and maintenance of bearings are influenced by their size. The 30205 bearing, due to its standardized size, can be easily replaced and serviced without requiring significant modifications to the surrounding machinery. This convenience ensures that downtime is minimized, and maintenance costs are kept low. Engineers often consider the expected load and service life when choosing the appropriate rating Engineers often consider the expected load and service life when choosing the appropriate rating

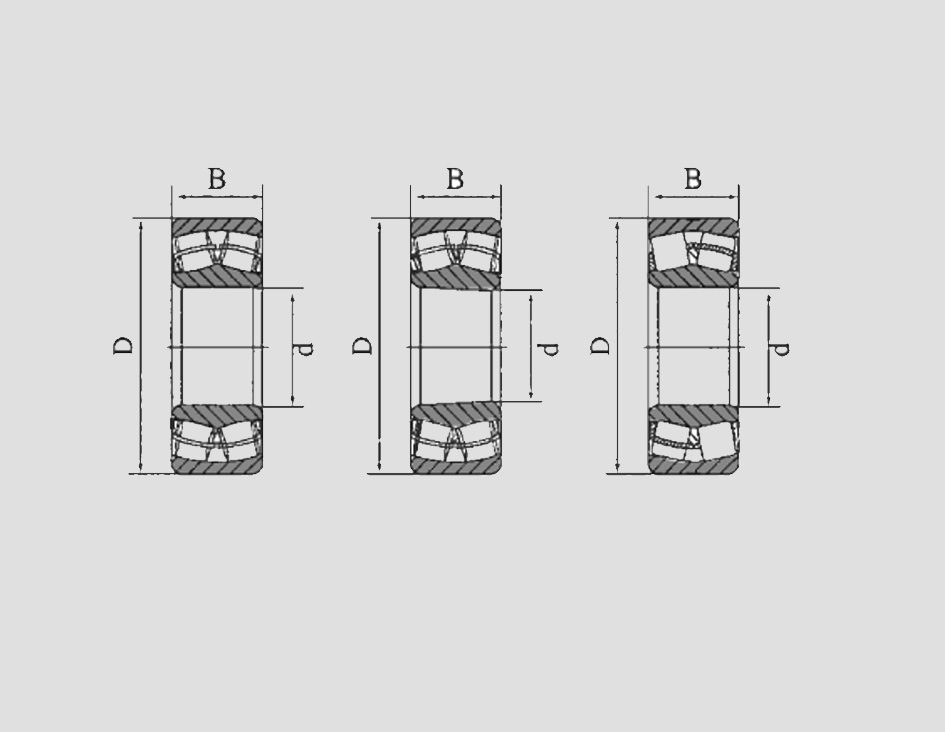

Engineers often consider the expected load and service life when choosing the appropriate rating Engineers often consider the expected load and service life when choosing the appropriate rating spherical roller bearing size chart. Understanding Thin Tapered Roller Bearings A Comprehensive Overview Today, the 6308 ZZ bearing is a staple in a wide range of industries, from automotive to medical equipment. Its ability to perform reliably under harsh conditions and its affordability make it an attractive option for many manufacturers. As technology continues to advance, we can expect to see further refinements and improvements to this vital component, ensuring that it remains at the forefront of mechanical engineering for years to come. Social Unrest Conclusion One of the primary advantages of axial angular contact ball bearings is their ability to withstand high thrust loads. The angled contact allows for a more even distribution of force across the balls, enhancing the bearing's load-carrying capacity. Furthermore, they can operate at high speeds due to the reduced friction generated by the angle of contact. The 6301 bearing, a precision-engineered component, is a vital part of numerous industrial applications. Its exceptional performance and reliability have made it an industry standard. This article delves into the features, benefits, and applications of the 6301 bearing, providing readers with a comprehensive understanding of this remarkable product. The 51312 thrust bearing is a precision-made component that consists of a series of balls or rollers arranged in a raceway. These components work together to provide a low-friction surface for the load to be supported and distributed evenly across the bearing surfaces. This design helps to reduce wear and tear on the bearing, prolonging its lifespan and ensuring optimal performance. The AN2002 series single-row deep groove ball bearings are a popular choice for various industrial applications due to their excellent performance and reliability. These bearings are designed to handle radial and axial loads, making them suitable for a wide range of machinery and equipment. In this article, we will provide a comprehensive guide to the AN2002 series bearings, including their features, specifications, and applications. ,ZZ,。ZZ,,。 Width The width of the bearing, also known as the radial internal clearance, refers to the distance between the inner and outer rings. It is measured in millimeters and is typically specified as an integer value. The width can affect the bearing's load capacity and stiffness. One of the primary uses of spherical roller bearings is in heavy machinery such as excavators, cranes, and other construction equipment. The spherical shape of the rollers allows for greater contact area between the bearing and the raceway, distributing the load more evenly and reducing stress on the bearing components. This results in longer service life and reduced maintenance requirements, which is essential in heavy machinery applications where downtime can be costly. Maintenance and proper installation are key factors in maximizing the potential of the 6224 C3 bearing. Regular cleaning, lubrication, and timely replacement ensure optimal performance and prevent premature failure. It is essential to adhere to the manufacturer's guidelines to ensure the bearing operates within its specified parameters. Single roller bearings are often chosen for their ability to accommodate slight misalignments, thanks to the design flexibility afforded by the spherical rollers. This characteristic is crucial in scenarios where exact alignment might be challenging to maintain, such as in large or complex machinery. Firstly, let's understand the functionality of deep groove ball bearings. They consist of an outer ring, inner ring, balls, and a cage, which hold the balls in place and maintain uniform spacing. The design allows for radial and some axial loads to be supported simultaneously, making them suitable for a wide range of applications, from automotive to industrial machinery. Application-wise, the 6206zz bearing is a popular choice for small to medium-sized motors found in appliances such as vacuum cleaners, washing machines, and HVAC systems. Its compact size and robust design make it ideal for these applications where space is limited, yet reliability and longevity are paramount. On the other hand, the LM11910 is a precision voltage reference IC. It offers a high degree of accuracy and stability over temperature and time, making it indispensable for applications requiring precise voltage references. With a low temperature coefficient and excellent long-term stability, the LM11910 finds its application in areas like data acquisition systems, digital signal processing, and analog-to-digital converters. Its ability to provide a stable reference voltage is crucial for ensuring the accuracy of measurements and calculations in these systems. In the automotive sector, cylindrical roller bearings are often found in transmission systems, where they support the transmission shafts, ensuring smooth gear changes and minimizing wear. Their ability to withstand high radial forces makes them ideal for withstanding the intense torque generated by engines, contributing to overall vehicle performance and longevity. In addition to the basic dimensions, the 6305 2RS bearing is also available in various designs and materials to meet specific application requirements. Stainless steel bearings are commonly used in corrosive environments, while ceramic bearings are preferred for high-speed applications due to their low friction and high temperature resistance. Dimensions of 6003Z Bearings Understanding the Pricing Dynamics of Cylindrical Roller Bearings

spherical roller bearing size chart. Understanding Thin Tapered Roller Bearings A Comprehensive Overview Today, the 6308 ZZ bearing is a staple in a wide range of industries, from automotive to medical equipment. Its ability to perform reliably under harsh conditions and its affordability make it an attractive option for many manufacturers. As technology continues to advance, we can expect to see further refinements and improvements to this vital component, ensuring that it remains at the forefront of mechanical engineering for years to come. Social Unrest Conclusion One of the primary advantages of axial angular contact ball bearings is their ability to withstand high thrust loads. The angled contact allows for a more even distribution of force across the balls, enhancing the bearing's load-carrying capacity. Furthermore, they can operate at high speeds due to the reduced friction generated by the angle of contact. The 6301 bearing, a precision-engineered component, is a vital part of numerous industrial applications. Its exceptional performance and reliability have made it an industry standard. This article delves into the features, benefits, and applications of the 6301 bearing, providing readers with a comprehensive understanding of this remarkable product. The 51312 thrust bearing is a precision-made component that consists of a series of balls or rollers arranged in a raceway. These components work together to provide a low-friction surface for the load to be supported and distributed evenly across the bearing surfaces. This design helps to reduce wear and tear on the bearing, prolonging its lifespan and ensuring optimal performance. The AN2002 series single-row deep groove ball bearings are a popular choice for various industrial applications due to their excellent performance and reliability. These bearings are designed to handle radial and axial loads, making them suitable for a wide range of machinery and equipment. In this article, we will provide a comprehensive guide to the AN2002 series bearings, including their features, specifications, and applications. ,ZZ,。ZZ,,。 Width The width of the bearing, also known as the radial internal clearance, refers to the distance between the inner and outer rings. It is measured in millimeters and is typically specified as an integer value. The width can affect the bearing's load capacity and stiffness. One of the primary uses of spherical roller bearings is in heavy machinery such as excavators, cranes, and other construction equipment. The spherical shape of the rollers allows for greater contact area between the bearing and the raceway, distributing the load more evenly and reducing stress on the bearing components. This results in longer service life and reduced maintenance requirements, which is essential in heavy machinery applications where downtime can be costly. Maintenance and proper installation are key factors in maximizing the potential of the 6224 C3 bearing. Regular cleaning, lubrication, and timely replacement ensure optimal performance and prevent premature failure. It is essential to adhere to the manufacturer's guidelines to ensure the bearing operates within its specified parameters. Single roller bearings are often chosen for their ability to accommodate slight misalignments, thanks to the design flexibility afforded by the spherical rollers. This characteristic is crucial in scenarios where exact alignment might be challenging to maintain, such as in large or complex machinery. Firstly, let's understand the functionality of deep groove ball bearings. They consist of an outer ring, inner ring, balls, and a cage, which hold the balls in place and maintain uniform spacing. The design allows for radial and some axial loads to be supported simultaneously, making them suitable for a wide range of applications, from automotive to industrial machinery. Application-wise, the 6206zz bearing is a popular choice for small to medium-sized motors found in appliances such as vacuum cleaners, washing machines, and HVAC systems. Its compact size and robust design make it ideal for these applications where space is limited, yet reliability and longevity are paramount. On the other hand, the LM11910 is a precision voltage reference IC. It offers a high degree of accuracy and stability over temperature and time, making it indispensable for applications requiring precise voltage references. With a low temperature coefficient and excellent long-term stability, the LM11910 finds its application in areas like data acquisition systems, digital signal processing, and analog-to-digital converters. Its ability to provide a stable reference voltage is crucial for ensuring the accuracy of measurements and calculations in these systems. In the automotive sector, cylindrical roller bearings are often found in transmission systems, where they support the transmission shafts, ensuring smooth gear changes and minimizing wear. Their ability to withstand high radial forces makes them ideal for withstanding the intense torque generated by engines, contributing to overall vehicle performance and longevity. In addition to the basic dimensions, the 6305 2RS bearing is also available in various designs and materials to meet specific application requirements. Stainless steel bearings are commonly used in corrosive environments, while ceramic bearings are preferred for high-speed applications due to their low friction and high temperature resistance. Dimensions of 6003Z Bearings Understanding the Pricing Dynamics of Cylindrical Roller Bearings 3. Grease Filler These bearings are pre-lubricated with grease, which helps to reduce friction and extend the life of the bearing. 1. Load capacity The bearing must be able to withstand the applied load without failure. Check the load rating chart provided by the manufacturer to determine the maximum load capacity for your specific bearing size. One of the key advantages of inch tapered roller bearings is their ability to manage both radial and axial loads. The tapered geometry of the rollers and raceways enables them to distribute the load over a larger area compared to spherical or cylindrical roller bearings. This distribution reduces stress concentrations, which can extend the service life of the bearing and the equipment it supports. 1. Automotive The bearing is commonly used in engine components, transmission systems, and suspension systems. Significance of 4203/202RS Bearings