Links:

Concrete attachments are an important part of any construction project, ensuring structural integrity, ease of construction and overall efficiency. These accessories range from basic items such as form ties and rebar to more specialized products such as curing blankets and expansion joints. Their main purpose is to support and strengthen concrete structures, making them more durable and resilient. By integrating high-quality concrete accessories into construction projects, builders can achieve better alignment, reduce labor costs, and accelerate project timelines. Additionally, using the right fittings can help prevent common problems such as cracking, misalignment, and premature wear, thereby extending the life of your concrete structure.

Molding accessories like falsework and shores are also indispensable. Falsework supports the formwork until the concrete sets, while shores, or props, provide additional support to prevent the formwork from collapsing under the weight of the wet concrete. Material Composition The primary material used in the production of welded wire is steel. The type of steel used can significantly impact the price of the wire. For example, stainless steel is more expensive than carbon steel due to its higher alloy content and superior corrosion resistance. Another advantage of the 6ft chain link fence is its low maintenance requirements Our collection of compression coil springs for sale offers a wide range of options to cater to diverse needs. From small, miniature springs for precision instruments to heavy-duty springs for industrial machinery, each product is meticulously crafted with attention to detail and quality. We understand that every application requires a specific spring rate, load capacity, and material, which is why our inventory includes a variety of spring sizes, wire diameters, and finishes. Wall ties, an essential component in masonry construction, play a pivotal role in maintaining the structural integrity of buildings. In this context, we delve into the specific application and significance of 200mm wall ties, an often-overlooked yet crucial element in construction engineering. Wire spring manufacturers play a crucial role in various industries, including automotive, electronics, and medical devices. These manufacturers specialize in producing wire springs, which are essential components that provide flexibility, resilience, and strength to many products. In this article, we will explore the importance of wire spring manufacturers and their impact on different sectors. In addition to their practicality, metal grid display boards also add a modern and industrial touch to any space. The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic

Our collection of compression coil springs for sale offers a wide range of options to cater to diverse needs. From small, miniature springs for precision instruments to heavy-duty springs for industrial machinery, each product is meticulously crafted with attention to detail and quality. We understand that every application requires a specific spring rate, load capacity, and material, which is why our inventory includes a variety of spring sizes, wire diameters, and finishes. Wall ties, an essential component in masonry construction, play a pivotal role in maintaining the structural integrity of buildings. In this context, we delve into the specific application and significance of 200mm wall ties, an often-overlooked yet crucial element in construction engineering. Wire spring manufacturers play a crucial role in various industries, including automotive, electronics, and medical devices. These manufacturers specialize in producing wire springs, which are essential components that provide flexibility, resilience, and strength to many products. In this article, we will explore the importance of wire spring manufacturers and their impact on different sectors. In addition to their practicality, metal grid display boards also add a modern and industrial touch to any space. The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic

The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way.

metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way. Concrete Mesh

One of the most significant benefits of using adjustable brick ties is the time and cost savings they offer adjustable brick tie. By reducing the need for custom-made ties and minimizing on-site modifications, builders can save significant amounts of time and money. This is particularly important in large-scale construction projects where time is of the essence and budget constraints are tight. Industrial Safety As we navigate through the labyrinth of emotions that accompany debonding, we might encounter resistance—fear of the unknown, grief for what was, or even guilt for choosing the path less traveled. Yet, it is through confronting these emotions head-on that we cultivate resilience and learn to trust the mystery of unfolding destiny. We understand that every ended chapter opens room for a new story, rich with potential and promise We understand that every ended chapter opens room for a new story, rich with potential and promise

adjustable brick tie. By reducing the need for custom-made ties and minimizing on-site modifications, builders can save significant amounts of time and money. This is particularly important in large-scale construction projects where time is of the essence and budget constraints are tight. Industrial Safety As we navigate through the labyrinth of emotions that accompany debonding, we might encounter resistance—fear of the unknown, grief for what was, or even guilt for choosing the path less traveled. Yet, it is through confronting these emotions head-on that we cultivate resilience and learn to trust the mystery of unfolding destiny. We understand that every ended chapter opens room for a new story, rich with potential and promise We understand that every ended chapter opens room for a new story, rich with potential and promise We understand that every ended chapter opens room for a new story, rich with potential and promise We understand that every ended chapter opens room for a new story, rich with potential and promise

We understand that every ended chapter opens room for a new story, rich with potential and promise We understand that every ended chapter opens room for a new story, rich with potential and promise debonding ties. In conclusion, stucco wire is a valuable material in construction due to its excellent crack resistance, versatility, and ease of installation. Whether you are building a new home or renovating an existing one, stucco wire is a smart choice for adding strength and durability to your project. With its many benefits and wide range of applications, it is no wonder that stucco wire continues to be a popular choice among builders and contractors alike. Trellises, on the other hand, are ideal for vining plants such as pothos or ivy. These lattice-like structures provide a surface for the plant's vines to climb, promoting vertical growth and saving floor space. Trellises can be freestanding or attached to walls, offering both functionality and visual interest. Metal grid display boards are also highly customizable, allowing users to easily change the layout and arrangement of items on the board. You can easily rearrange your display to highlight new products or promotions, making it a versatile and cost-effective option for businesses that frequently update their displays. Coil springs, an integral component in various engineering applications, play a pivotal role in absorbing and storing mechanical energy. These versatile springs, available for sale across numerous platforms, are widely used in automotive, industrial, and even household equipment due to their exceptional load-bearing capacity and resilience. Furthermore, the wire is employed in the manufacturing of staple pins, nails, and other fasteners, where resistance to corrosion is paramount. In telecommunications, galvanizing wire is used in overhead ground wires, providing both conductivity and durability. In conclusion, steel frame wall ties are the unsung heroes of building construction, providing resilience, longevity, and efficiency to structures. As the building industry continues to evolve, the reliance on these sturdy connectors will likely increase, further solidifying their status as an indispensable element of modern architecture. The Vibrancy of Tomato Stands for Sale A Glimpse into Local Agriculture In addition to providing support and air circulation, the 12% tomato cage also helps to improve the overall appearance of the garden. By keeping the tomato plant upright and organized, the cage creates a tidy and attractive look in the garden

debonding ties. In conclusion, stucco wire is a valuable material in construction due to its excellent crack resistance, versatility, and ease of installation. Whether you are building a new home or renovating an existing one, stucco wire is a smart choice for adding strength and durability to your project. With its many benefits and wide range of applications, it is no wonder that stucco wire continues to be a popular choice among builders and contractors alike. Trellises, on the other hand, are ideal for vining plants such as pothos or ivy. These lattice-like structures provide a surface for the plant's vines to climb, promoting vertical growth and saving floor space. Trellises can be freestanding or attached to walls, offering both functionality and visual interest. Metal grid display boards are also highly customizable, allowing users to easily change the layout and arrangement of items on the board. You can easily rearrange your display to highlight new products or promotions, making it a versatile and cost-effective option for businesses that frequently update their displays. Coil springs, an integral component in various engineering applications, play a pivotal role in absorbing and storing mechanical energy. These versatile springs, available for sale across numerous platforms, are widely used in automotive, industrial, and even household equipment due to their exceptional load-bearing capacity and resilience. Furthermore, the wire is employed in the manufacturing of staple pins, nails, and other fasteners, where resistance to corrosion is paramount. In telecommunications, galvanizing wire is used in overhead ground wires, providing both conductivity and durability. In conclusion, steel frame wall ties are the unsung heroes of building construction, providing resilience, longevity, and efficiency to structures. As the building industry continues to evolve, the reliance on these sturdy connectors will likely increase, further solidifying their status as an indispensable element of modern architecture. The Vibrancy of Tomato Stands for Sale A Glimpse into Local Agriculture In addition to providing support and air circulation, the 12% tomato cage also helps to improve the overall appearance of the garden. By keeping the tomato plant upright and organized, the cage creates a tidy and attractive look in the garden

12 tomato cage. This can be especially important for gardeners who take pride in the appearance of their outdoor spaces. Size and quantity are also important considerations when determining the price of compression springs. Larger springs or springs with a higher load capacity will generally cost more than smaller springs. Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit compression spring price. Manufacturers often offer discounts for larger orders, so it's important to consider your quantity needs when shopping for compression springs. In the realm of construction and industrial applications, half-inch wire mesh has proven to be an indispensable material. This versatile product, known for its durability and strength, is used in a wide array of settings, each requiring a unique set of properties from the mesh. Butterfly ties are typically made from corrosion-resistant materials such as stainless steel or galvanized steel, ensuring their durability and longevity. This makes them suitable for use in a variety of different environments, including coastal areas where exposure to saltwater can lead to corrosion. The use of high-quality materials also helps to ensure that butterfly ties will continue to provide reliable structural support for many years to come. One of the primary benefits of wholesale cattle fencing is its affordability. By purchasing materials in bulk, farmers can save money on upfront costs and labor expenses. This can be especially beneficial for smaller farms or those on a tight budget. Additionally, wholesale fencing suppliers often offer discounts on large orders, further reducing the overall cost of the project. } IBuffer buffer = IBuffer.allocate(inputVideo.length); How to Select the Right Welded Mesh Supplier In addition, supported plants often have better access to sunlight. Sunlight is crucial for photosynthesis, the process by which plants convert light energy into chemical energy for growth. When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields

compression spring price. Manufacturers often offer discounts for larger orders, so it's important to consider your quantity needs when shopping for compression springs. In the realm of construction and industrial applications, half-inch wire mesh has proven to be an indispensable material. This versatile product, known for its durability and strength, is used in a wide array of settings, each requiring a unique set of properties from the mesh. Butterfly ties are typically made from corrosion-resistant materials such as stainless steel or galvanized steel, ensuring their durability and longevity. This makes them suitable for use in a variety of different environments, including coastal areas where exposure to saltwater can lead to corrosion. The use of high-quality materials also helps to ensure that butterfly ties will continue to provide reliable structural support for many years to come. One of the primary benefits of wholesale cattle fencing is its affordability. By purchasing materials in bulk, farmers can save money on upfront costs and labor expenses. This can be especially beneficial for smaller farms or those on a tight budget. Additionally, wholesale fencing suppliers often offer discounts on large orders, further reducing the overall cost of the project. } IBuffer buffer = IBuffer.allocate(inputVideo.length); How to Select the Right Welded Mesh Supplier In addition, supported plants often have better access to sunlight. Sunlight is crucial for photosynthesis, the process by which plants convert light energy into chemical energy for growth. When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields

When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields When plants are allowed to grow vertically, they can reach for more sunlight, resulting in increased productivity and larger yields plant support.

plant support. Furthermore, stucco diamond mesh is easy to install and requires minimal maintenance. Once the mesh is in place and covered with a layer of stucco, it can last for many years without needing repairs or replacements. This makes it a cost-effective solution for long-term construction projects and renovations.

Manufacturing processes are a focal point in the PDF. It explains the weaving process, where wires are interlaced to form a fabric, and the welding process, where individual wires are fused at their intersections for added strength and durability. The document also highlights the significance of material selection, with steel, stainless steel, aluminum, and other metals commonly used, each offering unique properties suited to specific tasks. For security purposes, diamond wire mesh is a preferred choice for fencing and window guards In conclusion, extending spring with %2212%\22 is a powerful approach for enhancing the flexibility and efficiency of spring-based applications. By capitalizing on the framework's extensive ecosystem and well-defined extension points, developers can introduce customized solutions tailored to their unique business requirements while preserving the robustness and scalability of spring's core architecture. As businesses continue to evolve and demand more sophisticated applications, the value of %2212%\22-powered spring extensions will only grow. In addition to the practical advantages, the florist wire wholesale market contributes to the sustainability of the floral industry. Many wholesalers now offer eco-friendly options, such as biodegradable wires, catering to the growing demand for environmentally conscious products. 6.(Fence Netting)、,。,。

One of the key benefits of stucco diamond mesh is its ability to enhance the strength and stability of structures. By adding a layer of stucco-coated mesh to walls or ceilings, builders can increase the load-bearing capacity of the surface and reduce the risk of cracks or other damage. This is especially important in areas prone to seismic activity or extreme weather conditions.

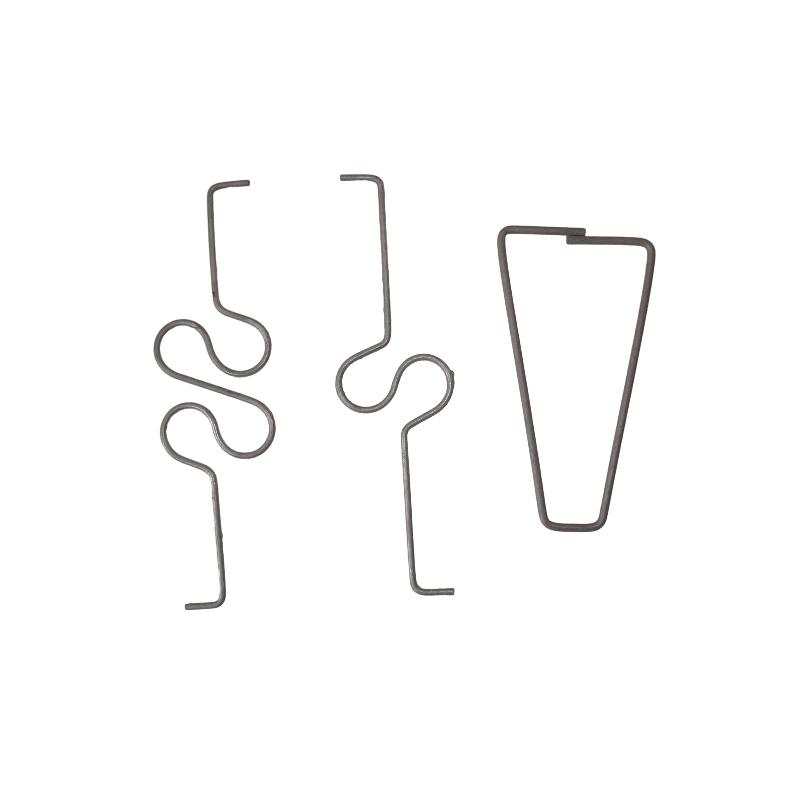

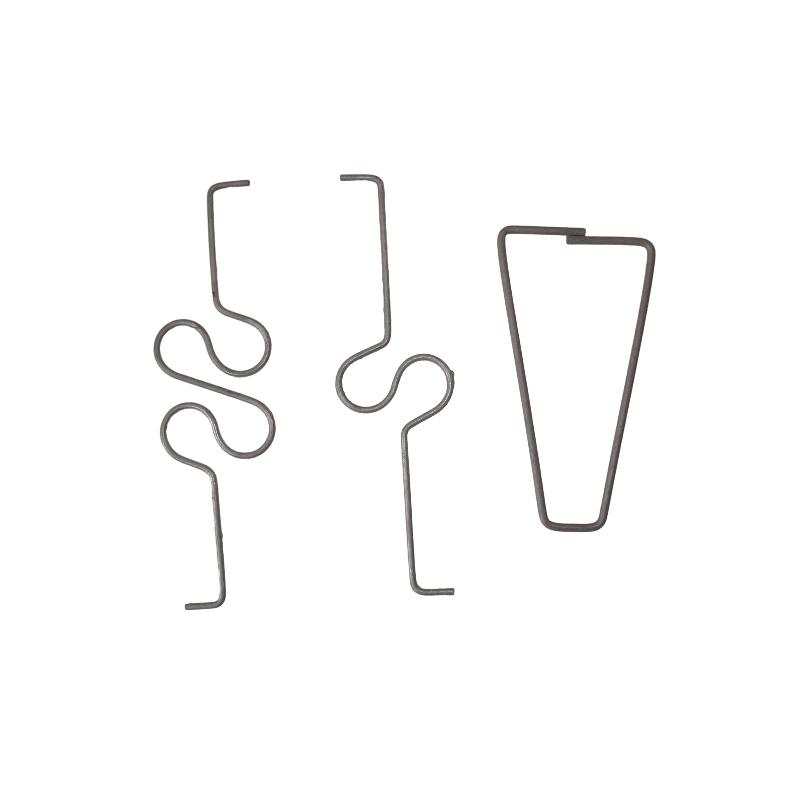

Snake Spacers is a story about the quest for knowledge, the journey of self-discovery, and the wonder of the universe. It challenges us to look beyond the boundaries of our own perception and reality, and to embrace the unknown as a source of endless possibility and adventure. In conclusion, square metal grid panels are more than just functional components; they are design elements that seamlessly integrate form and function. Their versatility, strength, and aesthetic allure make them a popular choice in architecture, engineering, and beyond. As technology advances and sustainability becomes a priority, square metal grid panels are poised to play an even greater role in shaping our built environment. Metal stucco lath is also a cost-effective choice, as it can help to reduce the overall maintenance and repair costs of a building. Its durable construction means that it will require minimal upkeep over time, saving both time and money for the building owner. PVC chicken wire, also known as vinyl-coated wire mesh, is a popular material used in various applications due to its durability, affordability, and versatility. This type of wire mesh is made by coating galvanized steel wires with polyvinyl chloride (PVC), which provides a protective layer that prevents rust and corrosion. As a result, PVC chicken wire retains its strength and integrity for an extended period, making it an ideal choice for long-term projects. Field wire fencing is a popular choice for securing properties and boundaries in rural and agricultural settings. This type of fencing is made up of strong wire that is woven or welded together to create a durable barrier that keeps out unwanted animals and intruders. One of the key advantages of galvanized mesh fencing is its versatility. It can be used to create a variety of fences, including privacy fences, pool fences, and security fences. The open design of the mesh allows for easy visibility, making it an excellent choice for security purposes. Additionally, the fence can be easily customized to fit your specific needs, whether you need a tall fence for added privacy or a shorter fence for a more open feel. In addition to improving structural integrity, brick ladder reinforcement also enhances the thermal performance of the wall. The steel bars or wires used in the reinforcement help conduct heat more efficiently, resulting in better insulation and reduced energy costs. This is especially beneficial in colder climates, where maintaining a comfortable indoor temperature is essential. 3/8 rib lath is a critical material in the construction industry, particularly in the process of stucco application. It serves as a supportive base for the stucco to adhere to, providing both strength and stability to the exterior walls. This article delves into the intricacies of 3/8 rib lath, its composition, usage, and significance.

Galvanized iron wire also plays a vital role in construction and infrastructure projects beyond its use as binding wire. In industrial construction, the wire is utilized for various purposes, such as securing scaffolding, reinforcing concrete structures, and installing fencing around construction sites. Its strength and durability make it suitable for withstanding the rigors of construction work, ensuring that temporary structures remain stable and secure throughout the building process. Additionally, galvanized iron wire is used in the installation of electrical wiring and communication cables, providing a reliable means of support and protection for these essential infrastructure components.

When designing a 1% 8% compression spring, several factors must be taken into consideration 1 8 compression spring. The material of the spring, the diameter of the wire, the number of coils, and the pitch of the coils all play a crucial role in determining the performance of the spring. It is essential to calculate the exact dimensions and specifications of the spring to ensure that it can withstand the required amount of force and compression without failing.

1 8 compression spring. The material of the spring, the diameter of the wire, the number of coils, and the pitch of the coils all play a crucial role in determining the performance of the spring. It is essential to calculate the exact dimensions and specifications of the spring to ensure that it can withstand the required amount of force and compression without failing. Brick veneer anchors are specialized ties used specifically to attach a brick veneer to a structural backing. These anchors ensure that the aesthetically pleasing brick facade remains securely attached to the underlying structure, which could be wood, steel, or concrete. Brick veneer anchors are designed to accommodate the slight movement that can occur between the veneer and the backing without compromising the integrity of the facade. They come in various designs, including corrugated metal, Z-shaped, and adjustable anchors, each providing different benefits depending on the specific requirements of the project. Proper installation of brick veneer anchors is essential to ensure that the brick facade performs well under various environmental conditions while maintaining its visual appeal.

Brick wire ties, an often-overlooked component in construction, play a crucial role in the stability and integrity of structures. These small, yet sturdy connectors are the silent heroes that bind bricks together, turning individual units into robust walls and frameworks.