Links:

Conclusion

2. Official Honda Dealerships

.

1. Visual Inspections Regularly check the belt for signs of wear, such as cracks, fraying, or glazing on the surface. Any visible damage could lead to belt failure, which can result in serious engine issues.

1. Machinery and Equipment

What is a Timing Belt?

Choosing the correct belt size is paramount to machine effectiveness. Here are a few tips for selecting the right 3pk belt

5. Testing and Validation After creating a custom serpentine belt, rigorous testing is essential to verify that it meets all operational requirements. This includes running the belt through various performance scenarios to ensure reliability, efficiency, and durability in real-world conditions.

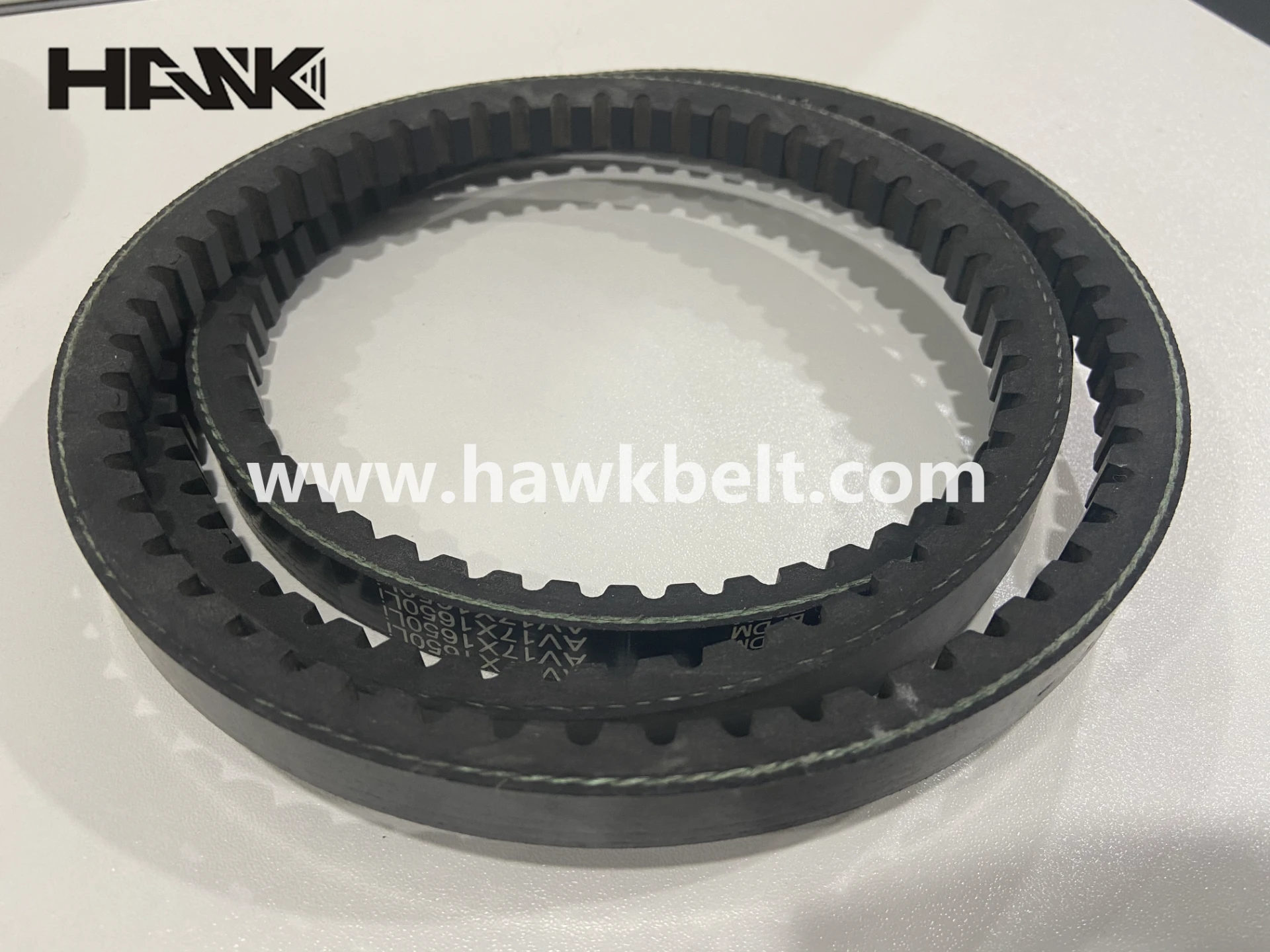

A V-belt is a type of mechanical belt that has a trapezoidal cross-section, resembling the letter “V.” This design allows the belt to fit snugly into V-shaped grooves on the pulleys, providing a larger surface area for maximum grip and reducing slippage. V-belts are commonly made from rubber or synthetic materials, which offer durability and flexibility, making them suitable for high-performance applications.

Signs of Wear and Tear

Importance of Standard Sizes

Flat Belt Drive

One of the defining features of PK belts is their durability. Made from high-quality rubber compounds, they can withstand significant stress and strain, which makes them ideal for demanding environments. Furthermore, PK belts can be used in both static and dynamic applications, offering flexibility in design and implementation.

3. Brake Systems Safety should always be a priority, and the brake system of the Fiat Uno is integral to this. From brake pads and discs to calipers and brake fluid, ensuring that these parts are in good condition is critical. Regular checks and replacements will keep the braking system responsive and reliable.

For those unfamiliar with selecting the right V-belt size, measuring the length of an existing belt can be beneficial. When measuring, follow these steps

3. Industrial Machinery Various industrial machinery, including conveyor systems and packaging equipment, utilize EPDM PK belts for power transmission. Their durability and resistance to degrading elements ensure consistent performance in demanding conditions.

Understanding the Timing Belt with 129 Teeth Importance, Function, and Maintenance

1. Regular Cleaning Dust and debris can accumulate around the belt, causing wear and tear. Periodically inspect and clean the area to prevent buildup.

Purchasing a timing belt is not just about finding the cheapest option available. It’s crucial to prioritize quality, compatibility, and brand reputation. Regularly inspect your timing belt and adhere to replacement intervals to avoid engine problems. If you’re in the market for a timing belt, take the time to do your research and choose wisely—your engine will thank you for it! Whether you're a DIY enthusiast or seeking professional help, taking care of your timing belt is an essential part of vehicle maintenance that should never be neglected.

सर्पेंटाइन बेल्टची योग्य देखभाल करणे अत्यंत आवश्यक आहे कारण तो वेळेनुसार धूसर आणि खराब होऊ शकतो. वर्षातून एकदा देखभाल करणे उचित असते. बेल्टमध्ये हरकत, फाटणे किंवा गाळीचे लक्षण दिसल्यास त्याला तात्काळ बदलावे लागेल. योग्य देखभाल न केल्यास, बेल्ट तुटण्याचा धोका असतो, जो वाहनाच्या कार्यक्षमतेवर परिणाम करू शकतो.

serpentine belt use

V-belts, or wedge belts, have a trapezoidal cross-section that allows them to handle higher loads than traditional flat belts. The ribs on the 6PK belt increase friction and enhance power transmission efficiency, allowing these belts to operate smoothly even under high-stress conditions. This design is especially critical in settings where reliability and durability are paramount.

In the automotive industry, belts such as serpentine belts, timing belts, and V-belts are critical components that ensure the engine runs smoothly. These belts transfer power from the engine to various accessories like the alternator, power steering pump, and water pump. The importance of high-quality belts in these applications cannot be overstated, as they directly influence the performance and reliability of vehicles.

2. Visible Wear and Cracking On inspection, you may notice fraying, cracks, or other signs of deterioration on the belt itself.

Multiribbed belts are primarily used in automotive engines, where they serve as a single belt solution for multiple accessories. This design simplifies the belt system, reducing weight and space requirements while improving overall efficiency. Common applications include

Moreover, the environmentally conscious trend of sustainable fashion encourages consumers to seek out bargains. Buying discounted products is a way to reduce waste and promote a more sustainable approach to fashion. By choosing discounted PK belts, you’re not only saving money but also contributing to a more sustainable shopping culture. More people are becoming aware of the impact of fast fashion, and making thoughtful purchases is a step towards responsible consumerism.

1. Simplicity and Versatility Flat belt drives are relatively simple in design and can be used for various applications, making them versatile. They can handle multiple pulleys, allowing for complex setups in machinery.

2. Reduced Back Pain Motorcycle riding can put significant strain on the lower back due to the position in which riders sit. Many bikers experience motorcycle back, a term used to describe back pain caused by the unnatural posture and vibrations from the bike. A back support belt acts as a brace, providing essential support to the lumbar region and alleviating discomfort.

3. Timing Chains

timing belt types

Poly-V belts, also known as poly-V or serpentine belts, are increasingly becoming the go-to choice for various machinery applications due to their efficiency, versatility, and durability. One of the most notable variations in this category is the TB2 belt. Understanding the advantages and specifications of Poly-V TB2 belts can help manufacturers and engineers make informed decisions.

2. Reduced Wear and Tear Cogged belts are typically made from durable materials such as neoprene or polyurethane, which can withstand considerable wear and environmental conditions. This durability extends the life of the belt compared to non-cogged alternatives.

Applications of Flat Drive Belts

The Influence of Social Media

2. Increased Power Transmission Double sided timing belts can handle higher loads due to their ability to engage with two pulleys simultaneously. This characteristic allows for more efficient power transmission, which is vital in high-performance environments.

In summary, engine belts are crucial components that contribute significantly to the performance and longevity of Nissan vehicles. Whether it's the serpentine belt driving multiple accessories or the timing belt ensuring perfect engine timing, regular maintenance and timely replacement are paramount. By staying diligent in monitoring the condition of these belts, you can avoid unexpected breakdowns and maintain your Nissan's performance. Remember, when it comes to vehicle maintenance, an ounce of prevention is worth a pound of cure. So keep an eye on those engine belts - they play a critical role in your vehicle's health!

As correias dentadas de aço são ideais para aplicações que exigem um suporte robusto e resistência imbatível. Elas são frequentemente utilizadas em maquinários pesados e em sistemas onde há grandes tensões e cargas. Embora sejam mais pesadas que as correias de poliuretano ou borracha, sua resistência e durabilidade as tornam essenciais em ambientes industriais exigentes.

3. Enhanced Durability The heat joining process not only creates a stronger bond but also allows for the incorporation of advanced materials that can withstand harsh operating conditions. These belts are engineered to resist abrasion, heat, and chemical exposure, ensuring a longer lifespan and reduced maintenance needs.

1. Floor Mats and Liners Protection Against Wear and Tear

In Italy, sourcing genuine Iveco parts is a feasible and beneficial endeavor for vehicle owners and operators alike. Whether through authorized dealers or local automotive shops, you can find the necessary components to keep your Iveco in top shape. By prioritizing genuine parts and adhering to maintenance best practices, you can ensure that your vehicle not only retains its value but also continues to perform at its best. In the fast-paced world of commercial transport, every part matters, and investing in quality will always pay off.

Conclusion

Conclusion

Qu'est-ce qu'une Courroie de Distribution ?

Improved Grip and Stability

2. Proper Alignment Ensure that the pulleys are properly aligned. Misalignment can lead to uneven wear and premature failure of the belt.

Tooth belt drives are a sophisticated and highly effective means of power transmission in numerous applications. Their precise operation, low maintenance, and efficient performance make them a popular choice across multiple industries. As technology continues to advance, we can expect to see further innovations in tooth belt drive systems, enhancing their capabilities and applications even more. Whether in automotive engines, industrial machinery, or consumer products, tooth belt drives are likely to remain a crucial part of modern engineering solutions.

3. Alignment Check Always check the alignment of the pulleys. Misaligned pulleys can cause uneven wear and premature failure of the belt.

Conclusion

5. Weight Savings PU V belts are often lighter than their rubber counterparts. This weight reduction can lead to slight improvements in fuel efficiency, making a car more economical to operate.

- Unusual Noises If you hear squealing, grinding, or banging noises during operation, it could indicate that the belt is slipping or is misaligned.

The Importance of Motorcycle Primary Chain and Belt Systems