Links:

- Sports and Recreation Rubber insulation tape, also known as electrical tape, is an essential tool in the world of electrical engineering and maintenance. This versatile material plays a critical role in ensuring safety, efficiency, and longevity in various electrical applications. One of the key advantages of Diall self-fusing tape is its ease of use. Unlike traditional tapes that require adhesive to stick, this tape simply bonds to itself when stretched and wrapped around an object. This makes it ideal for sealing leaks, repairing hoses, bundling wires, and more. The tape is also waterproof and weather-resistant, ensuring a reliable seal in any conditions.

Sealing air pipes

Window glazing tape (15063B) is a closed-cell, double-coated foam tape with a poly liner. The tape is one-sixteenth of an inch thick, widths range from one-fourth of an inch (6 millimeters) to one inch (24 millimeters), and it is available in black or white. Window glazing tape (15123B) is a thicker option at one-eighth of an inch thick.

In addition to its adhesive strength, automotive fabric tape is also designed to be flexible and conformable. This allows the tape to easily mold to the shape of the surface it is being applied to, ensuring a smooth and seamless finish. Whether you are working on curved areas, corners, or intricate patterns, automotive fabric tape can be easily manipulated to meet your specific needs.Cable management is another area where amalgamating rubber tape shines. It can be used to bundle and protect cables, providing an extra layer of insulation and shielding from external elements. The tape's ability to conform to irregular shapes and surfaces makes it a versatile tool for organizing and securing cables in both residential and commercial settings.

One key application of 50mm wide insulation tape is in electrical wiring. It's used to insulate live wires, prevent accidental contact with conductive surfaces, and secure loose connections. In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification

In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification

In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification In industrial settings, it's often employed for cable harnessing, bundling, and marking different wire types or voltage levels for easy identification 50mm wide insulation tape. - **Use a Straight Edge** Use a straight edge to apply the tape in a straight line, ensuring a professional appearance.

50mm wide insulation tape. - **Use a Straight Edge** Use a straight edge to apply the tape in a straight line, ensuring a professional appearance. What Temp does Electrical Tape Melt?

3 1. High dielectric strength This property allows the tape to withstand high voltage without breaking down or conducting electricity. The benefits of a well-installed rubber strip are immediate and long-lasting Moreover, insulation cotton tape is widely used in the automotive industry. It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance

1. High dielectric strength This property allows the tape to withstand high voltage without breaking down or conducting electricity. The benefits of a well-installed rubber strip are immediate and long-lasting Moreover, insulation cotton tape is widely used in the automotive industry. It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance

It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance It is used to insulate wires, cables, and components in vehicles to prevent interference and improve electrical system performance insulation cotton tape. The tape is also used to protect wires and cables from abrasion and corrosion, ensuring their longevity and reliability.

insulation cotton tape. The tape is also used to protect wires and cables from abrasion and corrosion, ensuring their longevity and reliability. How to Use Silicone Self-Adhesive Tape?

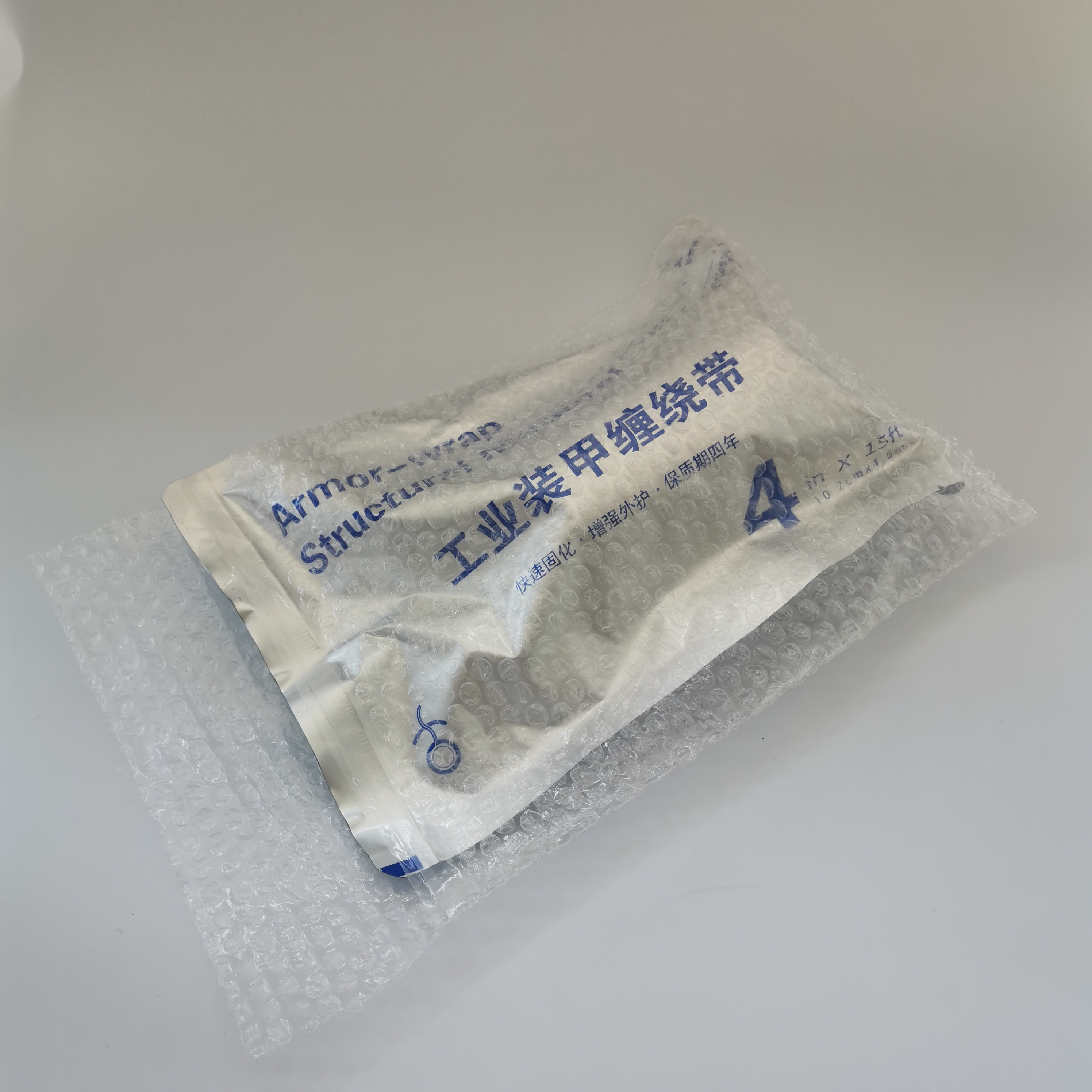

The Importance of Door Seal Tape in Enhancing Energy Efficiency and ComfortFlex Tape Black 4 in x 5 ft is a powerful and versatile waterproof tape that can be used for a wide range of applications. This black tape is designed to provide a strong and durable seal that can withstand even the harshest conditions. Whether you need to fix a leaky pipe, repair a broken fence, or patch up a hole in your boat, Flex Tape Black is the perfect solution.

Moreover, butyl rubber tape is non-toxic and safe for use in various applications, including food-related contexts. This makes it a great choice for sealing appliances, packaging, or other areas where food safety is a concern. Its versatility extends to a range of industries, including automotive, construction, electronics, and more.