Links:

5. Visual Inspection Cracks, fraying, or signs of wear on the timing belt indicate that it may need replacement.

Power steering systems are essential for modern vehicles, providing drivers with the ease of maneuverability and responsiveness. At the heart of many power steering systems lies the power steering pump, which is crucial for converting the driver’s steering input into appropriate tire movement. One of the vital components that ensure the pump operates effectively is the power steering pump drive belt. In this article, we will explore the role of the power steering pump drive belt, its importance, signs of wear, and tips for maintenance.

Moreover, belt flats are increasingly being designed with versatility in mind

. Many modern designs are reversible, providing wearers with the option to switch between different colors and styles without needing multiple belts. This innovation aligns with sustainability trends in fashion, as consumers are encouraged to invest in fewer, high-quality pieces that offer greater functionality.belt flat

Conclusion

To understand 7PK belt sizes, it’s important to know how they are measured. The dimensions of a serpentine belt are typically indicated in millimeters, including its length and rib count. The length of the belt is critical, as it affects how well the belt fits within the system. For a 7PK belt, the length can vary widely based on the specific application, but they often range from around 700 mm to over 4000 mm.

Should a belt need replacement, it’s crucial to select the correct specifications to maintain the system’s performance. Following manufacturer guidelines for installation and periodic maintenance can extend the life of Synchroflex timing belts and contribute to the reliable operation of machinery.

The applications of PK % Blet metrics are diverse and can be found across various industries, including finance, healthcare, e-commerce, and beyond. For instance, in the financial sector, the importance of quickly and accurately accessing transaction data cannot be overstated. Even a slight delay can result in significant financial implications. By monitoring PK % Blet, financial institutions can identify areas for optimization and ensure that their database operations remain swift and efficient.

As technology evolves, so too does the world of conveyor belts. The future is likely to witness advancements such as

5. Consistent Performance With a chain belt system, there is less chance of slippage, allowing for more consistent power delivery and improved handling.

Maintenance and Replacement

There are primarily two types of motorcycle chain systems roller chains and o-ring chains.

What Is the Primary Drive System?

Although the timing belt is classified as a maintenance-free component, certain signs indicate that it may need to be replaced. Here are some common signs to watch out for

1. Inspection A mechanic will assess the condition of the timing belt and related components, including tensioners and pulleys.

- Automotive Industry In automotive engines, double sided belts can help synchronize camshafts and crankshafts, ensuring smooth engine operations and improvements in performance.

The Role of V Belts

- A ratchet and socket (if required)

Performance and Handling

for mitsubishi space wagon

Lämpöliitosajohihna on tekninen innovaatio, joka on saanut huomattavaa huomiota teollisuudessa viime vuosina. Tämä erikoisteknologia tarjoaa monia etuja perinteisiin liitostekniikoihin verrattuna, ja sen käyttömahdollisuudet ovat laajentuneet merkittävästi.

When it comes to purchasing an alternator belt, balancing cost and quality is essential. While cheaper options may seem appealing, investing in a durable new serpentine belt or eco drive belt ensures long-term savings through reduced maintenance and improved engine performance.

- Cost-Effectiveness Compared to other power transmission systems, such as gears and chains, belts are often more affordable and easier to replace.Design and Operation

Conclusion

4. Home Appliances Many household appliances, such as washing machines and food processors, utilize rubber toothed belts to drive various components, ensuring smooth operation and longevity.

4. Home Appliances Cogged belts are also found in various household appliances, such as washing machines and treadmills, where they play a crucial role in transmitting power effectively.

1. High Load Capacity The ribbed design of the 8PK belt allows it to handle significant torque loads and offers superior grip on pulleys. This capability is critical in applications where power is transmitted across several components simultaneously.

Functionality of the Belt

2. Improved Performance With efficient power transfer and reduced energy loss, universal V-belts contribute to enhanced overall performance of machinery, allowing for better productivity.

When it comes to motorcycle riding, safety and style are paramount. Among the many accessories a rider can choose from, a leather motorcycle belt often stands out as a symbol of both functionality and fashion. The following exploration delves into the reasons why leather motorcycle belts have become a staple in the riding community, their historical significance, and how to choose the right one for your needs.

The conveyor belt is more than just a mechanical device; it is a symbol of innovation that has shaped the modern industrial world. From its humble beginnings to its current state as a cornerstone of efficiency and productivity, the conveyor belt continues to evolve, adapting to the challenges of today’s economy. Its contributions to safe working environments, reduced labor costs, and enhanced operational efficiency will ensure its place in the heart of industrial processes for years to come, paving the way for a more productive and sustainable future.

Installing a timing belt like the 535-5M-15 requires precision and care. Either a professional mechanic or an experienced e-scooter owner can undertake the installation process, which typically involves the following steps

Conveyor belts are vital elements of modern industrial processes, facilitating the efficient movement of goods and materials across various operations. Among the various types of conveyor belts available, ribbed conveyor belts stand out due to their unique design and capabilities. This article delves into the features, applications, and advantages of ribbed conveyor belts in different sectors.

1. Slippage Flat belts are more prone to slippage compared to V-belts, especially under heavy loads.

- Professional Assistance If you’re not comfortable inspecting or replacing the timing belt yourself, seek professional assistance. A certified mechanic will have the expertise to handle this critical task efficiently.

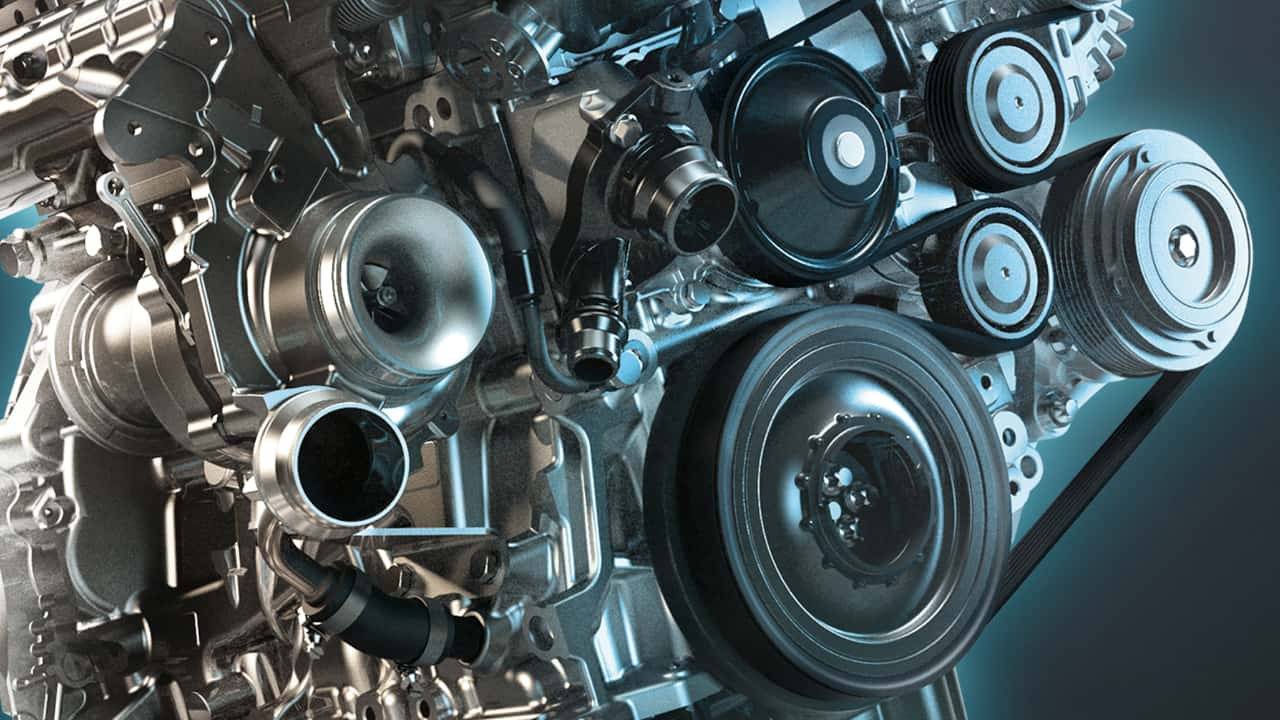

A tensioner belt pulley is part of the vehicle's serpentine belt system, which drives multiple accessories such as the alternator, water pump, power steering pump, and air conditioning compressor. The tensioner itself is a spring-loaded or hydraulic device that maintains tension on the serpentine belt, ensuring it remains tight enough to function properly without slipping or breaking. The pulley, which is an integral part of this mechanism, assists in guiding the belt around the engine's various pulleys while providing the necessary tension.

Conclusion

3. Reduced Noise Belts operate more quietly than chains, which can be a comfort for riders who enjoy the serenity of the road rather than the clanking noise of a chain-driven bike.

In critical situations, the reliability of an emergency fan belt ensures that you can get your truck back on the road with minimal downtime. By carrying a spare in your vehicle, you are prepared to tackle unexpected belt failures without waiting for roadside assistance.

3. Contamination Dust, dirt, and other contaminants can wear down the belt's teeth, affecting its performance.Applications of Timing Belt Motors

Double sided timing belts represent an advanced solution to the challenges of power transmission in various mechanical systems. Their design offers compactness, efficiency, and a range of applications, making them a valuable choice in modern engineering. As industries continue to evolve and demand continues to grow for high-performance machinery, double sided timing belts are likely to play an increasingly vital role in achieving operational excellence. Understanding their advantages and applications is crucial for engineers and manufacturers aiming for innovation and efficiency in their designs.

4. Round Belts These are more flexible than flat belts and are ideal for smaller, lighter applications, such as in small machinery or conveyor systems.

drive belt suppliers

Several factors can affect the positioning and effectiveness of the Pk Belt within a company's supply chain. These include market trends, seasonal variations, lead times from suppliers, and customer buying behaviors. For instance, during peak seasons, businesses may need to adjust their Pk Belt to accommodate an increase in demand, ensuring that they do not fall short of meeting customer expectations. Meanwhile, during off-peak seasons, they may choose to lower their Pk Belt to avoid excess inventory that would incur unnecessary holding costs.

There are several types of V-belts used in automotive applications, each designed for specific purposes and configurations

- Robotics Double sided timing belts provide precision control over movement in robotic applications, where space efficiency and high load capacities are crucial.

Understanding and Buying Serpentine Belts A Comprehensive Guide

When considering V-belt pulleys, understanding the factors influencing their prices is essential for making informed and strategic purchasing decisions. Quality, size, manufacturing processes, and supplier reputation all play pivotal roles in pricing. By carefully evaluating these factors and exploring different options, businesses can find the right V-belt pulley that meets their operational needs without exceeding their budget. Whether you are sourcing for a small workshop or a large manufacturing facility, investing time in research will yield significant long-term benefits.

5. Ozone and Weather Resistance

Advantages of Chains

Conclusion