Links:

-

In the vast array of fencing options, the welded wire fence stands out as a versatile and practical solution for a variety of applications. Measuring at a standard height of 6 feet, this type of fencing is particularly popular due to its durability, strength, and cost-effectiveness. Whether you're looking to secure your residential property, enclose livestock, or protect agricultural crops, a 6ft welded wire fence can provide an effective barrier without breaking the bank. Overall, plasterboard external corner bead is an indispensable tool for anyone looking to achieve a flawless and professional-looking finish on their walls. Its durability, versatility, and ease of use make it a must-have item for anyone involved in construction or renovation projects. So why wait? Invest in a high-quality plasterboard external corner bead today and transform your walls from drab to fab! One of the best places to find cheap tomato cages is online. There are many websites and online marketplaces that offer a wide variety of tomato cages at discounted prices. You can easily compare prices and find the best deal that fits your budget. Some websites even offer free shipping, making it even more cost-effective to purchase tomato cages online.

Black Annealed Wire: Crafting Functional Tools

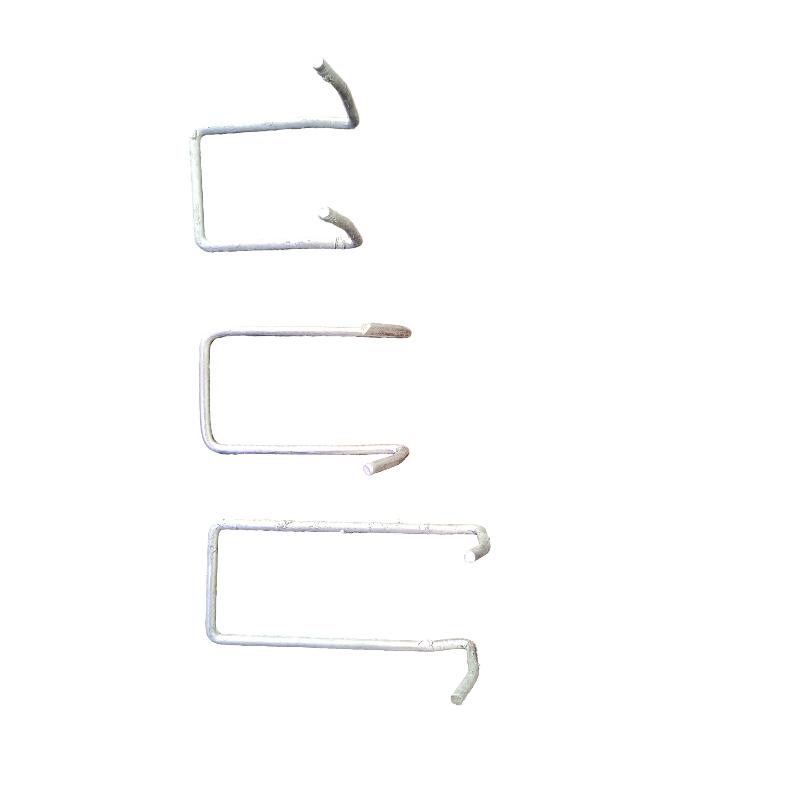

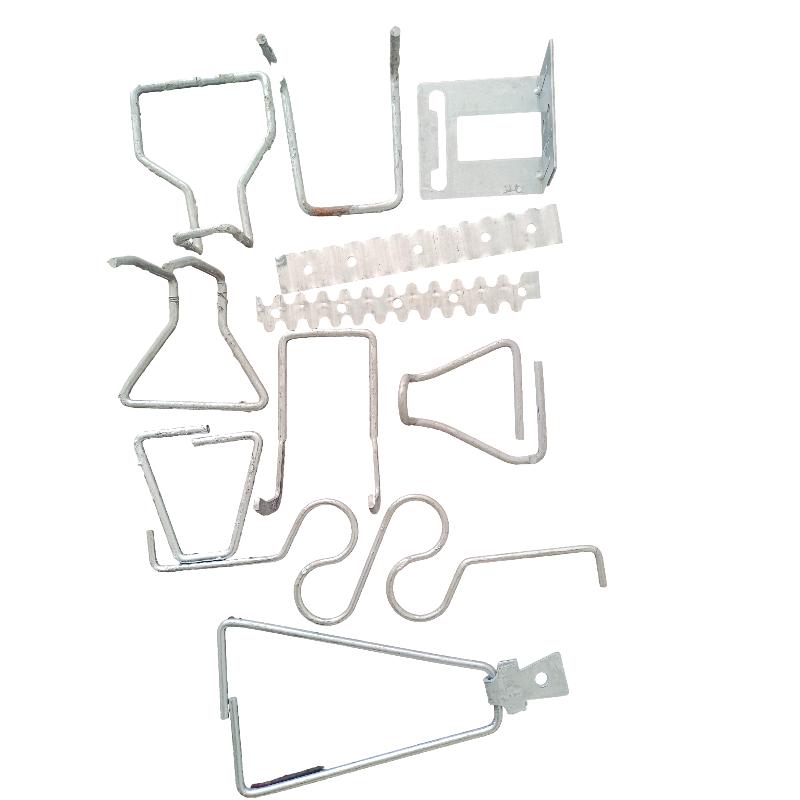

The installation process of these ties requires precision and expertise. It involves drilling holes into the masonry, applying a suitable adhesive, and then inserting the tie to create a strong bond. This method ensures minimal disruption to the brick's surface, preserving both its appearance and structural integrity. These extra tall cages, standing at a height of 7 feet or more, are engineered to accommodate the exuberant growth of tomatoes, providing ample space for their branches to spread without becoming entangled or breaking under the weight of the fruit. Their sturdy construction, often featuring thicker wires and reinforced joints, ensures durability against the rigors of weather and the heft of a bountiful harvest. Steel wall ties, often made from stainless steel or galvanized steel to withstand harsh weather conditions and resist corrosion, are slender metallic rods with a hook or anchor at each end. They are designed to span the cavity between two leaves of a wall, providing a secure link that distributes loads evenly and maintains the overall coherence of the structure. Their importance is not merely functional but also safety-centric, as they prevent any potential collapse due to shear forces or differential settlement. Moreover, weld mesh sheets provide excellent fire resistance. When exposed to fire, the concrete acts as a thermal barrier, protecting the steel reinforcement from extreme heat. The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure

The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure The mesh itself also has a high melting point, further delaying the spread of flames throughout the structure weld mesh sheets. As a result, buildings reinforced with weld mesh sheets are more resistant to fire damage and can help ensure the safety of occupants during fires. In modern times, long metal stakes have found new roles in science and technology. Geologists use them as survey markers, aiding in the precise mapping of the Earth's crust. Engineers employ them in construction projects, anchoring foundations and securing scaffolding. Even in the field of renewable energy, solar panel installers utilize metal stakes to secure photovoltaic arrays to the ground.

weld mesh sheets. As a result, buildings reinforced with weld mesh sheets are more resistant to fire damage and can help ensure the safety of occupants during fires. In modern times, long metal stakes have found new roles in science and technology. Geologists use them as survey markers, aiding in the precise mapping of the Earth's crust. Engineers employ them in construction projects, anchoring foundations and securing scaffolding. Even in the field of renewable energy, solar panel installers utilize metal stakes to secure photovoltaic arrays to the ground. HD coil springs, also known as heavy-duty coil springs, are a crucial component in the suspension system of a vehicle. They play a vital role in providing support and stability to the vehicle, especially when carrying heavy loads or navigating rough terrains.

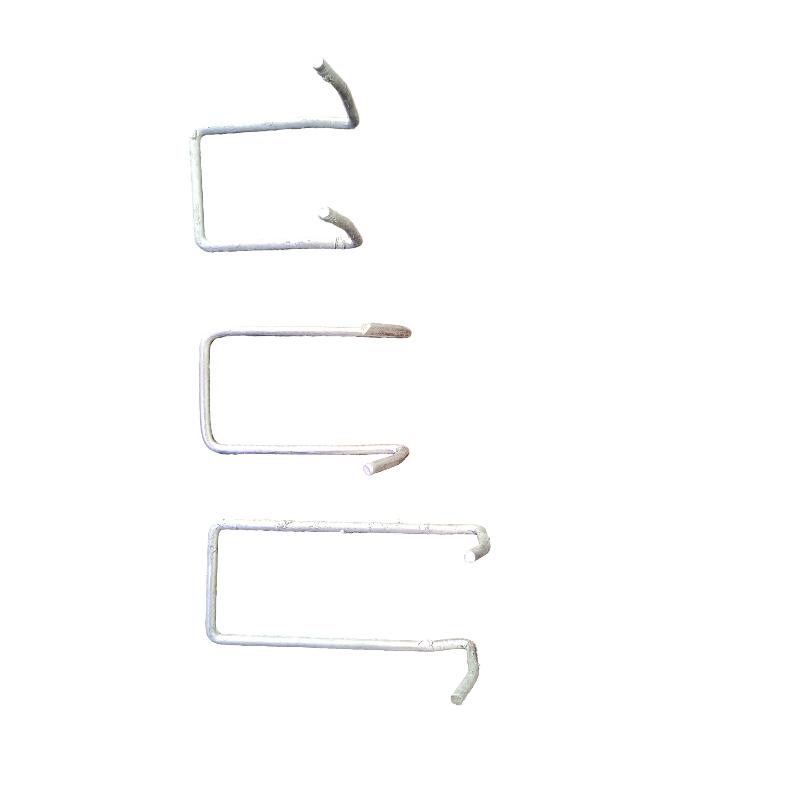

buffer = coder.encodeBuffer(buffer); Overall, wire h frames are an essential tool for anyone looking to create effective yard signs. Their versatility, ease of use, cost-effectiveness, and professional look make them a popular choice among businesses, politicians, and individuals alike. So the next time you need to create a yard sign, consider using wire h frames to get your message out there effectively. Small Coil Springs A Crucial Component in Precision Mechanics When choosing the right type of field fencing for your property, there are several factors to consider. The type of livestock you have, the size of your property, and your budget will all play a role in determining the best fencing option for your needs. It is also important to consider the terrain and weather conditions in your area, as these factors can impact the effectiveness and longevity of your fencing. Another critical factor in wire mesh quality is the choice of materials. Stainless steel is a popular choice due to its resistance to corrosion and longevity. However, depending on the specific application, other materials such as Galvanized steel or Black wire may be more appropriate. The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced

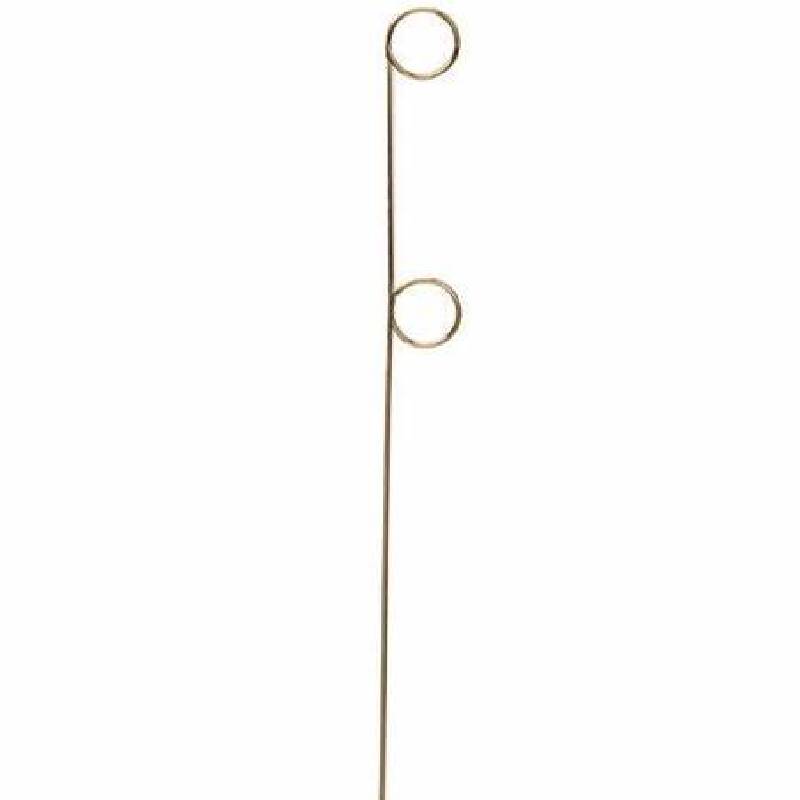

The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced The choice of material will depend on factors such as cost, environmental conditions, and the desired lifespan of the structure being reinforced reinforcement wire mesh size. The Art and Function of Curved Plant Supports In conclusion, the significance of welded wire manufacturers cannot be overstated. Their products are integral to countless industries, providing strength, stability, and security. As technology advances and new applications emerge, these manufacturers continue to evolve, adapting to changing needs and driving the progress of various sectors worldwide. They are the backbone of an interconnected global economy, quietly but powerfully contributing to the infrastructure and daily life we take for granted.

reinforcement wire mesh size. The Art and Function of Curved Plant Supports In conclusion, the significance of welded wire manufacturers cannot be overstated. Their products are integral to countless industries, providing strength, stability, and security. As technology advances and new applications emerge, these manufacturers continue to evolve, adapting to changing needs and driving the progress of various sectors worldwide. They are the backbone of an interconnected global economy, quietly but powerfully contributing to the infrastructure and daily life we take for granted. 10 Gauge galvanized wire

Galvanized iron wire plays a vital role in utilities and infrastructure, providing strong, durable, and corrosion-resistant support for electrical and communication lines, reinforcing utility structures, and securing critical infrastructure components. Its exceptional strength, durability, corrosion resistance, and cost-effectiveness make it an indispensable material for utility companies, contractors, and infrastructure developers. By ensuring the safety, reliability, and longevity of essential infrastructure systems, galvanized iron wire contributes to the efficient operation and sustainability of modern utility networks and infrastructure facilities.

What is Annealed Wire?Horizontal joint reinforcement is an integral component in masonry construction, crucial for enhancing the structural stability of walls. This reinforcement consists of steel wire placed within the mortar joints between masonry units. Its primary function is to control and mitigate the effects of cracking due to thermal expansion, contraction, and structural loads. By providing additional tensile strength, horizontal joint reinforcement helps in distributing loads more evenly across the wall, thus preventing localized stress concentrations that could lead to structural failures. This method is particularly beneficial in areas prone to seismic activity, where buildings must withstand lateral forces without compromising their structural integrity.

Overall, coated tomato cages are a must-have for any gardener looking to support and protect their tomato plants. With their durability, easy maintenance, and decorative appeal, they are a reliable and attractive option for any garden. Invest in a coated tomato cage today and watch your tomato plants thrive and flourish throughout the growing season. Despite their functional importance, masonry ties often go unnoticed, hidden within the walls they strengthen One of the primary uses of galvanized iron wire is in construction. It is commonly used as reinforcement in concrete structures, such as rebar in concrete slabs and beams, to increase their strength and durability. The zinc coating on the wire prevents rusting, which can weaken the concrete over time. Additionally, galvanized iron wire is also used in the installation of fences, gates, and other outdoor structures due to its resistance to corrosion and durability.Another benefit of adjustable compression springs is their ease of installation and maintenance. Unlike traditional compression springs, which are fixed in their compression length, adjustable compression springs can be easily adjusted without the need for specialized tools or equipment. This makes them a cost-effective and efficient option for many applications.

Another advantage of using brick reinforcement mesh is its ability to improve the thermal and acoustic properties of a brick wall

brick reinforcement mesh. By creating a barrier between the inner and outer layers of the wall, the mesh helps to reduce heat loss and noise transmission, creating a more comfortable and energy-efficient living or working environment. In conclusion, diamond wire mesh, with its unique diamond pattern and exceptional strength, has become an indispensable material across multiple industries. Its ability to provide both practical solutions and aesthetic enhancements underscores its true value. As technology advances and design aesthetics evolve, the potential of diamond wire mesh seems limitless, promising a future of innovative applications and artistic expressions.

galvanised steel mesh. The small openings in the mesh make it ideal for separating and filtering materials of different sizes, making it well-suited for use in industrial processes such as mining, agriculture, and waste management. The zinc coating helps to prevent corrosion and rust, ensuring that the mesh remains effective and efficient in these demanding environments. Galvanized iron wire is also commonly used in the electrical industry

galvanized iron wire. It is used to make electrical cables, ground wires, and other components that require high levels of conductivity and durability. The zinc coating helps prevent corrosion, ensuring that the wire maintains its electrical properties over time. This makes it an ideal material for use in harsh environments, such as outdoor lighting and industrial machinery. In the realm of construction and engineering, concrete reinforcing mesh suppliers play a pivotal role in shaping the robustness and durability of modern infrastructure. These specialized companies provide an essential component that enhances the strength and stability of concrete structures, ensuring they can withstand the test of time. Cattle field fencing is an essential component of any livestock operation. It serves as a barrier to keep cattle contained within a designated area, as well as a deterrent to predators and unwanted visitors. The type of fence used can vary depending on the specific needs of the operation, but it is crucial to choose a fence that is not only effective but also safe for the animals. Timber frame ties play a crucial role in ensuring the stability and strength of timber frame structures. They help to distribute the weight of the structure evenly and prevent it from shifting or collapsing. Without timber frame ties, timber frame structures would be much more susceptible to damage from strong winds, earthquakes, and other natural disasters

galvanized iron wire. It is used to make electrical cables, ground wires, and other components that require high levels of conductivity and durability. The zinc coating helps prevent corrosion, ensuring that the wire maintains its electrical properties over time. This makes it an ideal material for use in harsh environments, such as outdoor lighting and industrial machinery. In the realm of construction and engineering, concrete reinforcing mesh suppliers play a pivotal role in shaping the robustness and durability of modern infrastructure. These specialized companies provide an essential component that enhances the strength and stability of concrete structures, ensuring they can withstand the test of time. Cattle field fencing is an essential component of any livestock operation. It serves as a barrier to keep cattle contained within a designated area, as well as a deterrent to predators and unwanted visitors. The type of fence used can vary depending on the specific needs of the operation, but it is crucial to choose a fence that is not only effective but also safe for the animals. Timber frame ties play a crucial role in ensuring the stability and strength of timber frame structures. They help to distribute the weight of the structure evenly and prevent it from shifting or collapsing. Without timber frame ties, timber frame structures would be much more susceptible to damage from strong winds, earthquakes, and other natural disasters

timber frame ties.

Metal rib lath, an essential component in the construction industry, plays a pivotal role in various building applications, particularly in stucco and plastering works. This innovative material, characterized by its distinctive ribbed pattern, offers a robust and durable solution for enhancing structural integrity and aesthetics. Heavy duty garden wire is an essential tool for anyone who loves gardening or landscaping. This strong and durable wire can be used for a variety of purposes, from supporting climbing plants to creating sturdy fences and trellises. However, the selection and installation of timber frame wall ties require careful consideration. The choice of tie type depends on factors such as the size and height of the building, the expected wind loads, and the type of masonry being used. Installation must adhere to strict building regulations to ensure compliance with safety standards and to prevent potential problems like tie failure or moisture ingress. Welded mesh, also referred to as expanded metal or expanded steel mesh, is a type of metal fabric that is created by stretching a sheet of metal and then welding the strands together at regular intervals. This process results in a strong, lightweight, and porous material that can be used in a variety of applications.