Links:

-

The selection of the right type of expansion joint foam strip is crucial

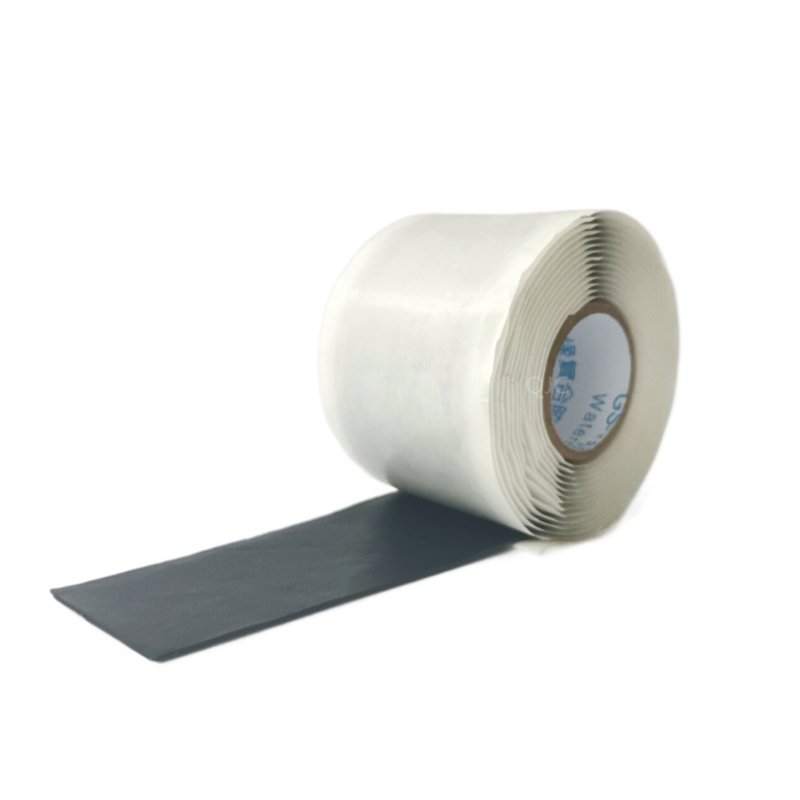

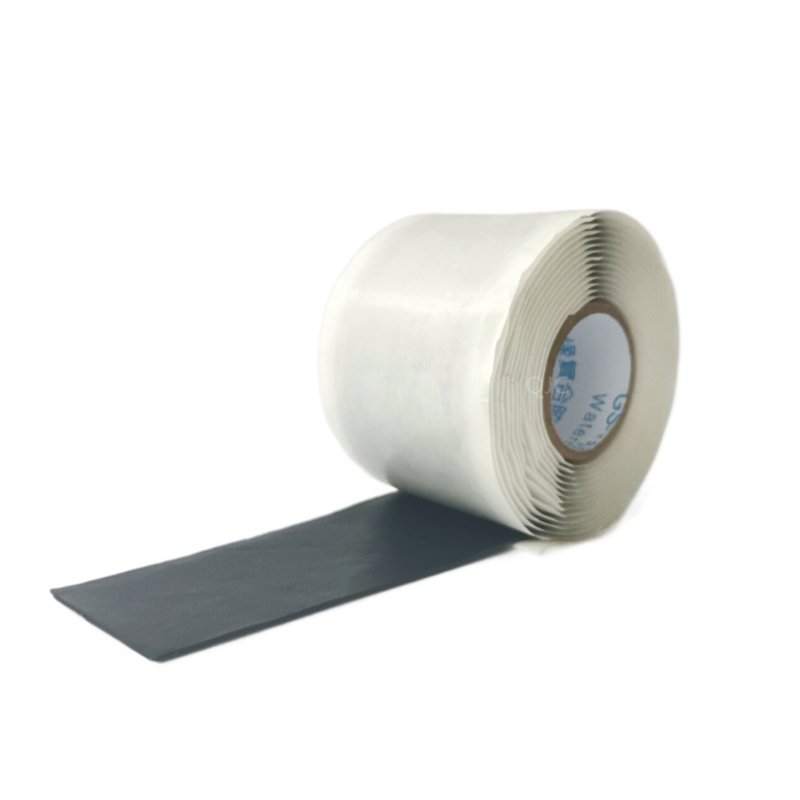

expansion joint foam strip. Factors such as the expected stress levels, environmental conditions, and the specific requirements of the structure all influence this choice. Engineers and architects often collaborate with material specialists to determine the most suitable foam strip, balancing durability, resilience, and cost-effectiveness. Overall, EPR self-amalgamating tape is a valuable tool for anyone working with electrical or plumbing systems. Its ease of use, versatility, and durability make it a reliable choice for a wide range of applications. Whether you're a professional tradesperson or a DIY enthusiast, this tape is sure to come in handy for all your sealing and insulating needs.

expansion joint foam strip. Factors such as the expected stress levels, environmental conditions, and the specific requirements of the structure all influence this choice. Engineers and architects often collaborate with material specialists to determine the most suitable foam strip, balancing durability, resilience, and cost-effectiveness. Overall, EPR self-amalgamating tape is a valuable tool for anyone working with electrical or plumbing systems. Its ease of use, versatility, and durability make it a reliable choice for a wide range of applications. Whether you're a professional tradesperson or a DIY enthusiast, this tape is sure to come in handy for all your sealing and insulating needs. When it comes to electrical tapes, 3M is the name of the game. But what makes these tapes stand out from the crowd? Well, let's break it down:

Self-amalgamating rubber tape, also known as pressure-sensitive tape, is a versatile and convenient solution for repairing various types of pipes, cables, and other electrical components. Its unique self-adhesive properties allow it to bond tightly to surfaces without the need for additional adhesives or solvents. In this article, we will discuss how to use self-amalgamating rubber tape effectively for repairs. One of the key advantages of auto electrical cloth tape is its durability. It is made from high-quality cloth material that is resistant to heat, moisture, and chemicals. This means that it can withstand the harsh conditions that are often present in automotive environments. You can trust that your repairs will last when you use auto electrical cloth tape. In addition to providing insulation, the 33kV HT insulation tape also offers protection against moisture, chemicals, and other environmental factors. This helps to maintain the integrity of the electrical system and reduces the risk of electrical failures or accidents

33 kv ht insulation tape. The Miraculous Power of Self-Adhesive Amalgamating Tape in Waterproof Applications On the other hand, green electrical tape holds a distinct role in the world of wiring and circuitry. It is specifically designated for earth or ground connections. In electrical systems, the green color signifies a safe path back to the ground, acting as an essential safety measure against electric shocks. Green electrical tape is used to identify and mark the grounding wire, ensuring that any excess electrical current finds its way safely back to the ground rather than posing a risk to people or equipment. This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations yellow and green electrical tape. The price of floor marking tape varies depending on several factors, such as the material, width, length, color, and brand. Generally, it ranges from $10 to $50 per roll, with larger rolls being more expensive but offering better value in terms of coverage area. Some premium brands may charge higher prices due to their superior quality, durability, and additional features like anti-slip properties or UV resistance. However, there are also many affordable options available that can provide satisfactory performance for basic applications.

yellow and green electrical tape. The price of floor marking tape varies depending on several factors, such as the material, width, length, color, and brand. Generally, it ranges from $10 to $50 per roll, with larger rolls being more expensive but offering better value in terms of coverage area. Some premium brands may charge higher prices due to their superior quality, durability, and additional features like anti-slip properties or UV resistance. However, there are also many affordable options available that can provide satisfactory performance for basic applications. Rubber tapes are an essential component in many industries, including construction, automotive, and electrical fields. These tapes are made from different types of rubber and used for various applications, such as sealing, insulation, and packaging. Here are some of the most commonly used rubber tapes:

1. Silicone Rubber Tape: This type of rubber tape is highly resistant to heat, cold, and moisture, which makes it ideal for electrical and electronic applications. It can also be used for sealing and insulating.

2. Butyl Rubber Tape: Butyl rubber tape is known for its high adhesive strength and excellent sealing properties. It is often used in the construction industry for sealing roofs, windows, and doors.

3. EPDM Rubber Tape: EPDM (ethylene propylene diene monomer) rubber tape is highly resistant to UV radiation and weathering, which makes it ideal for outdoor applications. It is often used for sealing or protecting joints, roofs, and facades.

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed It comes in different colors and patterns, allowing car enthusiasts to add a personal touch to their vehicles It comes in different colors and patterns, allowing car enthusiasts to add a personal touch to their vehicles

It comes in different colors and patterns, allowing car enthusiasts to add a personal touch to their vehicles It comes in different colors and patterns, allowing car enthusiasts to add a personal touch to their vehicles