Links:

-

4. Commercial Spaces Frosted glass is widely used in commercial spaces, such as hotels, restaurants, and offices, to create a sophisticated and professional atmosphere. It can be used for partitions, room dividers, and feature walls to add visual interest and enhance the overall aesthetic of the space.

- 4.Sustainable production: In recent years, the Chinese glass industry has also focused on sustainable production practices, including energy efficiency, waste reduction, and environmental protection. Many manufacturers have adopted cleaner production methods and are investing in green technologies to reduce their carbon footprint.

Tempered glass is created by heating ordinary glass to a temperature exceeding 600 degrees Celsius before rapidly cooling it with jets of air or water. This rapid cooling process causes the outer layers of the glass to contract and the inner layers to expand, resulting in a uniform distribution of stress throughout the glass. When the glass is subjected to impact, the stress points help to disperse the force, preventing the glass from shattering into dangerous shards. When choosing a tinted glass supplier, there are several factors to consider, including When looking for tempered glass sheets, it is crucial to compare prices from different suppliers to ensure you are getting the best deal. The price of tempered glass sheets can vary depending on various factors, including the size, thickness, and quality of the glass. Another advantage of ultra clear glass is its durability One of the key features of float glass is its ability to 'float' on molten metal during production. This method results in a consistently smooth and flat surface on both sides, making it ideal for applications where precision and uniformity are crucial. The float process also imparts excellent thermal stability, ensuring minimal expansion or contraction under varying temperatures. Another reason for its enduring popularity is its ability to adapt to changing trends. While some design styles come and go, pink frosted glass remains a constant. It can be incorporated into modern designs with ease, or it can be paired with classic furniture and accessories to create a timeless look. This adaptability makes it a versatile addition to any home decor collection. In conclusion, frosted glass treatment is a versatile and effective solution for enhancing privacy and aesthetic appeal in various settings. Its ability to diffuse light, provide privacy, and complement different design styles makes it a popular choice among homeowners, business owners, and designers alike. So, if you're looking to create a more comfortable and stylish living or working environment, consider incorporating frosted glass into your next project. The Patterned Glass Factory is committed to sustainability and environmentally friendly practices, using recycled materials whenever possible and implementing energy-efficient manufacturing processes to minimize its carbon footprint. By prioritizing sustainability, the factory is able to produce beautiful patterned glass products that not only enhance the aesthetic appeal of any space but also contribute to a healthier planet.

Additionally, Low-E glass plays a crucial role in sustainable building practices. By minimizing energy consumption, it helps decrease greenhouse gas emissions associated with heating and cooling systems. This aligns with global efforts to combat climate change and promotes the use of sustainable materials in construction.

low emissivity glass

In addition to product quality, customer service plays a crucial role in the success of acid-etched glass suppliers

acid etched glass suppliers. They need to provide excellent pre- and post-sales support, including assistance in design conception, accurate estimation, prompt delivery, and efficient installation. Many suppliers also offer repair and maintenance services to ensure customer satisfaction. In conclusion, the world of acid-etched glass suppliers is a dynamic and creative industry, blending artistry with technological advancements. From traditional craftsmanship to cutting-edge innovation, these suppliers play a vital role in transforming ordinary glass into stunning, functional works of art. As the demand for unique and sustainable design solutions grows, the importance of skilled and reliable acid-etched glass suppliers will only continue to rise. When it comes to IGU replacement, there are several important factors to consider. First and foremost, it is crucial to hire a professional glazier to assess the condition of the existing unit and determine the best course of action. Attempting to replace an IGU without the necessary expertise and equipment can result in subpar results and potential safety hazards. For interior designers, frosted glass is a versatile medium that can be wielded to craft partitions, decorative panels, or even artistic installations

acid etched glass suppliers. They need to provide excellent pre- and post-sales support, including assistance in design conception, accurate estimation, prompt delivery, and efficient installation. Many suppliers also offer repair and maintenance services to ensure customer satisfaction. In conclusion, the world of acid-etched glass suppliers is a dynamic and creative industry, blending artistry with technological advancements. From traditional craftsmanship to cutting-edge innovation, these suppliers play a vital role in transforming ordinary glass into stunning, functional works of art. As the demand for unique and sustainable design solutions grows, the importance of skilled and reliable acid-etched glass suppliers will only continue to rise. When it comes to IGU replacement, there are several important factors to consider. First and foremost, it is crucial to hire a professional glazier to assess the condition of the existing unit and determine the best course of action. Attempting to replace an IGU without the necessary expertise and equipment can result in subpar results and potential safety hazards. For interior designers, frosted glass is a versatile medium that can be wielded to craft partitions, decorative panels, or even artistic installations buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes. Overall, the integration of glass into window technology has ushered in a new era of sustainable and intelligent design. With their exceptional combination of thermal efficiency, natural light penetration, and smart capability, igu window glass are poised to play a leading role in shaping the future of architecture and homebuilding. Another popular type of reflective glass is low-e reflective glass. Low-e, or low emissivity, glass is coated with a thin layer of metal oxide that reflects heat back into the room while allowing visible light to pass through. This helps to improve insulation and reduce energy costs by minimizing heat loss in the winter and heat gain in the summer. Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings

buy frosted glass. Its matte finish provides texture and depth, breaking the monotony of plain surfaces. And when it's time for illumination, frosted glass lampshades cast a dance of patterns on walls, bringing static rooms to life with moving shadows and shapes. Overall, the integration of glass into window technology has ushered in a new era of sustainable and intelligent design. With their exceptional combination of thermal efficiency, natural light penetration, and smart capability, igu window glass are poised to play a leading role in shaping the future of architecture and homebuilding. Another popular type of reflective glass is low-e reflective glass. Low-e, or low emissivity, glass is coated with a thin layer of metal oxide that reflects heat back into the room while allowing visible light to pass through. This helps to improve insulation and reduce energy costs by minimizing heat loss in the winter and heat gain in the summer. Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings

Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings Low-e reflective glass is ideal for buildings that require high levels of thermal performance, such as energy-efficient homes and commercial buildings types of reflective glass.

types of reflective glass. In summary, float glass is an incredibly versatile material that serves numerous applications across different industries. From its role in architecture and automotive manufacturing to interior design and solar energy solutions, float glass meets various functional and aesthetic needs. Its unique properties—such as optical clarity, strength, and adaptability—make it an indispensable choice for professionals looking to achieve both style and functionality in their projects. As technology progresses and the demand for sustainable materials increases, float glass will likely continue to play a vital role in shaping our built environment and everyday experiences.

Silver, known for its exceptional reflective properties, has been used in mirrors for centuries. Its ability to provide a clear, undistorted reflection makes it an ideal material for makeup mirrors. Unlike ordinary mirrors, silver-coated mirrors offer enhanced clarity, allowing users to examine their features minutely, crucial for precise makeup application. The reflective surface of a silver makeup mirror allows one to see every detail, from the subtlest eyeliner stroke to the tiniest speck of mascara, ensuring a flawless finish every time. Moreover, architects and designers have harnessed the potential of reflectorized glass to create iconic structures that double as city landmarks

. Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings. 2

. Their surfaces, at once opaque and transparent, challenge our perception of space and volume. These buildings not only house functions but also invigorate urban landscapes with their dynamic interaction with the surroundings. 2 In addition to its practical benefits, frosted line glass can also add a touch of style and sophistication to any space. The defined lines or patterns in the glass can create a striking visual impact and can be used to add texture and interest to cabinets, doors, or partition walls. Frosted line glass can also be customised to suit individual preferences, with a wide range of patterns and designs available to choose from

In addition to its practical benefits, frosted line glass can also add a touch of style and sophistication to any space. The defined lines or patterns in the glass can create a striking visual impact and can be used to add texture and interest to cabinets, doors, or partition walls. Frosted line glass can also be customised to suit individual preferences, with a wide range of patterns and designs available to choose from

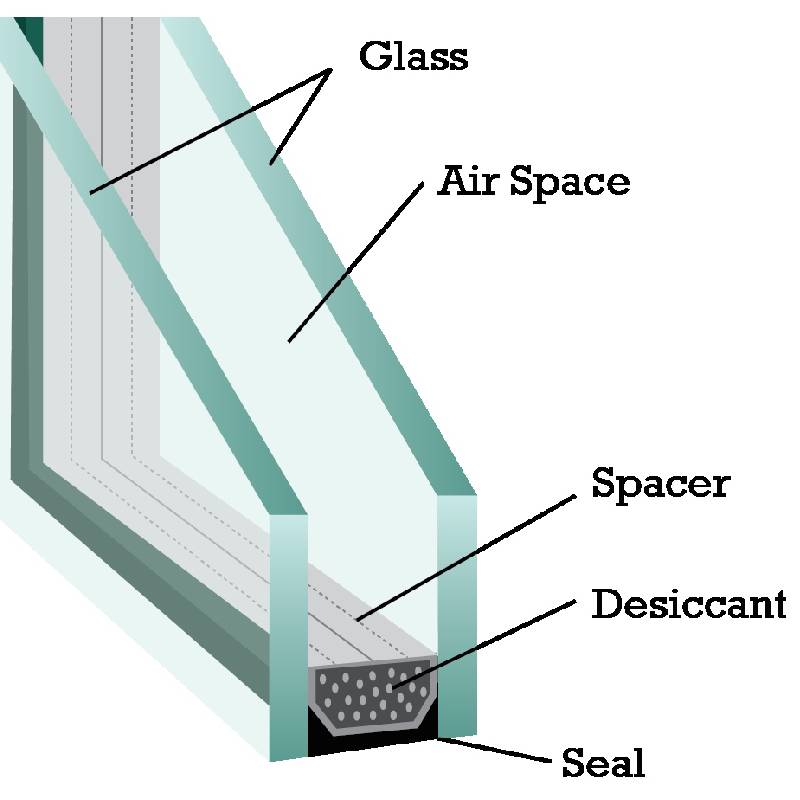

frosted line glass. The mirror's frame was crafted from sturdy aluminum, giving it a durable and long-lasting quality that would withstand the test of time. Its sleek lines and minimalist design made it a stylish addition to any room, whether it be a bedroom, bathroom, or living space. The primary advantage of these units lies in their ability to enhance thermal insulation. The trapped layer of air or gas between the glass panes acts as an insulator, reducing heat transfer and thereby keeping the indoor environment cooler in summer and warmer in winter. This significantly reduces the need for heating and cooling systems, translating into lower energy bills and a smaller carbon footprint.

One of the benefits of purchasing mirror glass for sale is that it can help to create the illusion of more space in a room. By strategically placing mirrors in different areas, you can make a room appear larger and more open. This is especially useful in smaller spaces where maximizing the feeling of openness is important.

In today's fast-paced world, energy efficiency has become a top priority for both residential and commercial buildings. One of the most effective ways to improve energy efficiency is by using low-emissivity (Low-E) glass. Low-E glass is a type of glass that has a thin, transparent layer of metal oxide coating on one or both surfaces. This coating helps to reduce the transfer of heat through the glass, making it an excellent choice for improving the energy efficiency of buildings.

One of the primary advantages of patterned glass is its ability to control light. The diffusion of natural light through textured surfaces can soften the harshness of direct sunlight, creating a pleasant atmosphere. This feature is particularly beneficial in spaces like bathrooms and office environments where privacy is paramount without compromising on natural light.

There are numerous benefits to using Low-E glass in buildings In the heart of a dimly lit chamber, there stood a captivating piece of art that whispered tales from eras long gone - a Silver Gothic Mirror. Its frame, intricately crafted with silver, was a testament to the finesse of Gothic artisans who wove stories into their work. The mirror, not just an object of utility, but a portal to the past, a silent observer of countless secrets and dreams. Moreover, Low-E glass not only regulates temperature but also offers excellent UV protection. It shields furniture, carpets, and artwork from fading due to harmful ultraviolet rays, preserving their color and quality over time. It also provides a degree of noise reduction, creating a tranquil living or working environment It also provides a degree of noise reduction, creating a tranquil living or working environment

It also provides a degree of noise reduction, creating a tranquil living or working environment It also provides a degree of noise reduction, creating a tranquil living or working environment

It also provides a degree of noise reduction, creating a tranquil living or working environment It also provides a degree of noise reduction, creating a tranquil living or working environment low e glass for sale. Yet, beyond aesthetics, reflective float glass serves a practical purpose

low e glass for sale. Yet, beyond aesthetics, reflective float glass serves a practical purpose One of the most captivating aspects of real silver mirrors is their ability to reflect light beautifully

. The silver layer heightened the brightness and clarity of reflected images, making them appear more vivid and life-like. This quality is especially appreciated in spaces where lighting is crucial, such as vanity areas and galleries.real silver mirror

Photovoltaic glass is a kind of packaging material used in photovoltaic modules, usually used as the cover glass of photovoltaic modules, the cover plate of double-glass components, the backplane glass and the substrate glass of thin film components are widely used, and its role is mainly to protect the battery from moisture and gas oxidation and corrosion electrodes, and extend the service life.

Enhancing Space and Light

Conclusion

In commercial environments, acid etched glass can be used effectively in office partitions, conference room doors, and even as decorative panels in lobbies. This not only adds a layer of sophistication to the office layout, but also promotes an open, airy feel. Businesses often opt for custom designs that reflect their identity or branding, further enhancing their image. The beauty of acid etched frosted glass lies in its ability to meld functionality with artistry.

acid etched frosted glass

In conclusion, understanding and implementing the concept of average replacement cost can significantly enhance a company's inventory management strategy. It provides a stable and realistic view of product costs, helping businesses to make informed decisions about their operations and financial planning. As such, it remains a valuable tool for maintaining competitiveness and ensuring long-term success in an ever-changing marketplace.

In addition to the initial cost of the blue reflective glass, it is also important to consider the long-term benefits and savings it can provide. Reflective glass can help reduce solar heat gain and UV exposure, potentially lowering cooling costs and extending the lifespan of furnishings and interior fabrics. Its reflective properties can also enhance natural light distribution and create a brighter, more inviting space.

The Silver Bubble Mirror is not just a beautiful object; it is a source of fascination and intrigue. Many have tried to uncover the secrets behind its creation, but to no avail. Some say it is the work of fairies, others believe it is the product of ancient magic Some say it is the work of fairies, others believe it is the product of ancient magic

Some say it is the work of fairies, others believe it is the product of ancient magic Some say it is the work of fairies, others believe it is the product of ancient magic

Some say it is the work of fairies, others believe it is the product of ancient magic Some say it is the work of fairies, others believe it is the product of ancient magic silver bubble mirror. But one thing is for certain the Silver Bubble Mirror holds a power that goes beyond the mere act of reflection. One of the main benefits of single glazed low e glass is its ability to reflect heat back into the building during the colder months, keeping the interior warm and comfortable. This can help to reduce the reliance on heating systems, resulting in lower energy bills and a more sustainable living environment. Additionally, the low e coating can also help to reduce glare and block out harmful UV rays, protecting furniture and other belongings from fading over time. Glass, often seen as fragile, is also incredibly durable. Our tempered glass products, like the sturdy glass coffee mugs and durable glass cookware, showcase this strength. They are built to withstand the rigors of daily use while maintaining their pristine appearance. Overall, a decorative bathroom window can be a stylish and functional addition to your space. By choosing the right window treatments and accessories, you can create a beautiful focal point that enhances the overall look and feel of your bathroom. Whether you opt for curtains, blinds, or decorative elements, there are plenty of options to suit your style and budget. Make your bathroom window a standout feature in your space and enjoy the natural light and style it brings to your daily routine.

silver bubble mirror. But one thing is for certain the Silver Bubble Mirror holds a power that goes beyond the mere act of reflection. One of the main benefits of single glazed low e glass is its ability to reflect heat back into the building during the colder months, keeping the interior warm and comfortable. This can help to reduce the reliance on heating systems, resulting in lower energy bills and a more sustainable living environment. Additionally, the low e coating can also help to reduce glare and block out harmful UV rays, protecting furniture and other belongings from fading over time. Glass, often seen as fragile, is also incredibly durable. Our tempered glass products, like the sturdy glass coffee mugs and durable glass cookware, showcase this strength. They are built to withstand the rigors of daily use while maintaining their pristine appearance. Overall, a decorative bathroom window can be a stylish and functional addition to your space. By choosing the right window treatments and accessories, you can create a beautiful focal point that enhances the overall look and feel of your bathroom. Whether you opt for curtains, blinds, or decorative elements, there are plenty of options to suit your style and budget. Make your bathroom window a standout feature in your space and enjoy the natural light and style it brings to your daily routine. Environmental Impact

Market demand is another essential factor that shapes the cost of 10mm float glass. Peak construction seasons or increased projects can drive up prices due to higher demand Peak construction seasons or increased projects can drive up prices due to higher demand10mm float glass price. Conversely, during economic downturns or low construction periods, manufacturers might reduce prices to stimulate sales

. The large silver heart-shaped mirror hung elegantly on the wall, its reflective surface capturing the beauty of the room. The intricate designs on the frame added a touch of sophistication to the mirror, making it a focal point in the space.

. The large silver heart-shaped mirror hung elegantly on the wall, its reflective surface capturing the beauty of the room. The intricate designs on the frame added a touch of sophistication to the mirror, making it a focal point in the space. Quality control is paramount in this process, as even minor imperfections can lead to significant flaws in the final product. Automated systems are often employed to monitor thickness and detect any anomalies during production. Once the glass sheets have cooled and been cut to size, they undergo further treatments if necessary, such as polishing, coating, or laminating.

In the world of art, reflective brown glass is a medium that invites creativity. Artists utilize its unique characteristics to create stunning sculptures, installations, and even stained glass pieces. The interplay of light and reflection creates a dynamic visual experience, making each piece a living, evolving work of art. As the light danced upon its surface, the burnished silver mirror seemed to come alive, its reflections shifting and changing like the tides of time

burnished silver mirror. It was as if the mirror held the power to travel through the years, offering glimpses of what once was and hints of what could be. To stand before it was to embark on a journey through the labyrinth of time, guided by the silent stories embedded within its silvered heart. Laminated float glass, another variant, consists of multiple layers bonded together with an interlayer, typically polyvinyl butyral. Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers

burnished silver mirror. It was as if the mirror held the power to travel through the years, offering glimpses of what once was and hints of what could be. To stand before it was to embark on a journey through the labyrinth of time, guided by the silent stories embedded within its silvered heart. Laminated float glass, another variant, consists of multiple layers bonded together with an interlayer, typically polyvinyl butyral. Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers

Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers Even when fractured, the glass adheres to the interlayer, preventing dangerous shards from dispersing—a characteristic that has earned it a place in windshields and protective barriers types of float glass.

types of float glass.