As we look to the future, barbed wire fencing continues to evolve. New materials and designs are being introduced, promising improved durability, aesthetics, and effectiveness. Yet, the fundamental principles established in the 19th century remain steadfast. Barbed wire fences symbolize resilience, practicality, and a connection to the land—a reflection of humanity’s ongoing negotiation with nature and the embodiment of our desire to create order amidst chaos.

In today’s world, where construction materials are evolving at a rapid pace, galvanized mesh panels have emerged as a preferred choice across various industries. These resilient and versatile panels are integral to numerous applications, including architectural design, agricultural fencing, and industrial security. In this article, we delve into the features, benefits, and applications of galvanized mesh panels, showcasing why they are a go-to solution for many projects.

In conclusion, galvanized welded mesh fencing offers a multitude of benefits that make it an ideal choice for various applications. Its durability, strength, versatility, low maintenance requirements, and eco-friendly characteristics set it apart from other fencing options. Whether for residential use, commercial security, or agricultural applications, galvanized welded mesh fencing is a reliable solution that meets the needs of today’s property owners while offering long-term value. Investing in this type of fencing is a wise decision for anyone looking to enhance security and boundary management effectively.

Constructing a 4' x 4' field fence involves several steps, starting with planning the layout of the fence. Farmers must choose the right materials and tools, which typically include fence posts, fencing wire, staples, and tensioning tools. The posts are crucial for providing stability; they should be evenly spaced, usually every 8 to 12 feet, and securely anchored in the ground.

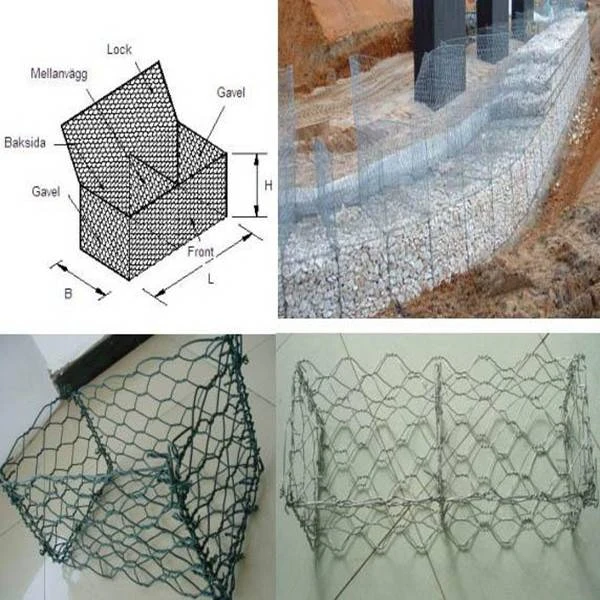

Moreover, wire mesh is generally resistant to rust and corrosion, particularly when made from galvanized steel or coated materials. This ensures that the fence remains sturdy and visually appealing over time, reducing the need for frequent replacements or repairs. Generating with stones also minimizes soil erosion, particularly in hilly or sloped areas, which can be beneficial for property owners concerned about landscape stability.

When it comes to securing properties, agricultural lands, or livestock areas, barbed wire fences are often a popular choice due to their effectiveness and affordability. However, potential buyers frequently ask what determines the price of barbed wire fences? The quest for understanding barbed wire fence prices involves several factors, including material quality, gauge, length, type of installation, and geographical location. In this article, we’ll explore these factors and provide insights to help you make an informed decision.

A vinyl chicken fence is a type of fencing specifically designed to contain chickens, while also providing a visually appealing barrier. Unlike traditional wood or chain-link fences, which can warp, rust, or deteriorate over time, vinyl fencing is made from durable, weather-resistant material that can withstand the elements without compromising its appearance. This makes it an excellent choice for those looking for longevity and minimal maintenance.

In the world of landscaping, aesthetics and functionality often go hand in hand, and one of the most compelling ways to achieve both is through the use of metal fencing trellises. These structures serve as a striking focal point in gardens, patios, and outdoor spaces, while also providing essential support for climbing plants, creating a harmonious blend of nature and design.

After shaping, blades are affixed to the wire. These blades are designed to cause maximum deterrence and injury to would-be intruders. Quality control is paramount during this phase, as even the slightest flaw can compromise the efficacy of the wire. Following this, the concertina wire is coiled into spirals, ready for packaging and shipment. Manufacturers need to keep up with technological advancements, employing modern machinery to ensure precision and efficiency in production.