Links:

- Calculation of bearing capacity Moreover, these mirrors serve as a window to the soul, quite literally. They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver

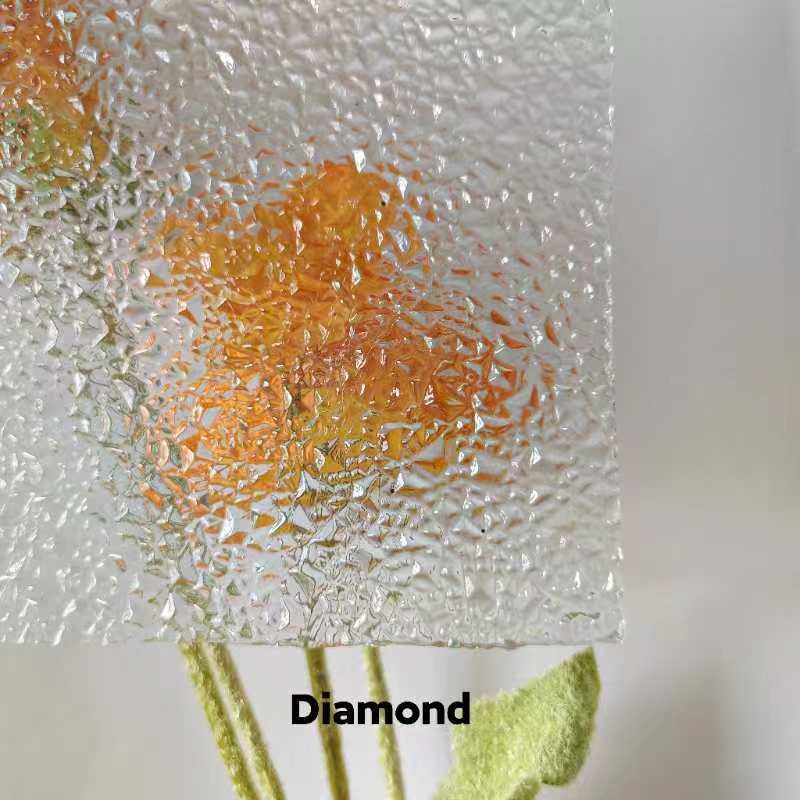

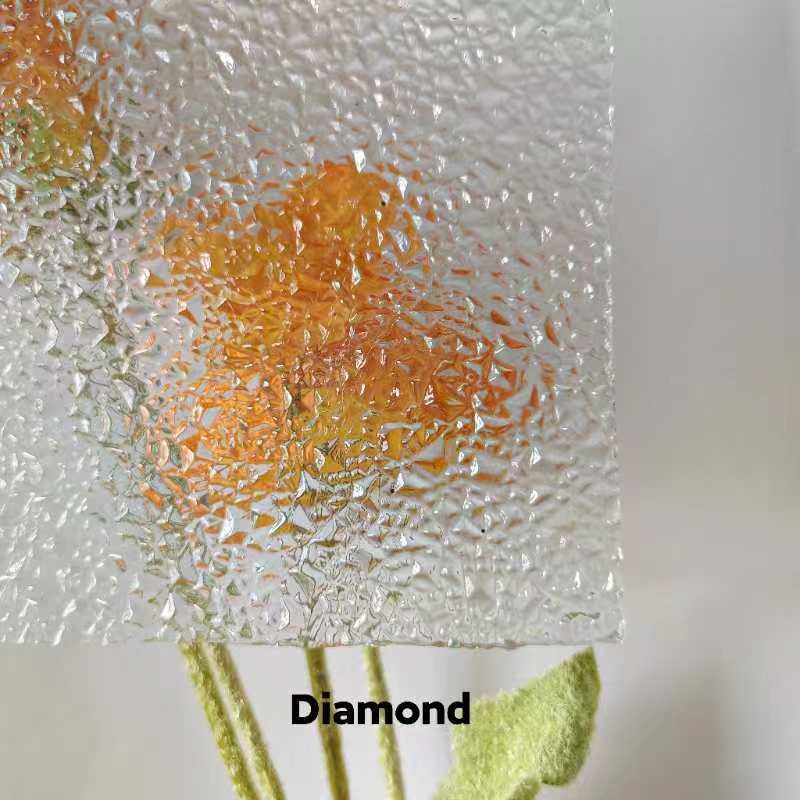

The Float Glass Factory A Gateway to Innovation in Glass Manufacturing

The silver carved mirror sparkled in the dimly lit room, casting a mesmerizing glow on the elegant surroundings. The intricate designs etched into the reflective surface seemed to dance in the flickering candlelight, creating an aura of mystery and magic. Furthermore, curved insulated glass units provide excellent sound insulation, helping to reduce noise pollution from outside sources. This can create a more peaceful and comfortable environment for building occupants, whether they are working, living, or relaxing inside. In the world of design and architecture, patterned glass has become a symbol of creativity and elegance. This unique form of glass is not merely a transparent barrier but an artistic medium that transforms light into a spectacle of colors and shapes. Patterned glass manufacturers are at the forefront of this revolution, blending traditional craftsmanship with modern technology to produce visually stunning results. Tempered glass is also commonly used in the automotive industry, where it is used in car windows and windshields. The strength of tempered glass makes it an ideal choice for protecting drivers and passengers in the event of a collision. 3. Entertainment Float glass video has the potential to revolutionize gaming and other entertainment industries, offering an unparalleled level of immersion and interactivity. Float glass is a type of high-quality glass that is commonly used in the construction industry. It is made by floating molten glass on molten tin, resulting in a smooth and flat surface. Float glass is known for its clarity, strength, and versatility, making it a popular choice for windows, doors, and other applications. The float glass making process begins with raw materials such as silica sand, soda ash, limestone, and other additives being mixed together and heated to a high temperature in a furnace. Once the materials have melted and formed a viscous liquid, they are poured onto a bath of molten tin. The molten glass spreads out evenly over the surface of the tin, forming a smooth sheet. The transparency of 6mm clear float glass makes it an ideal candidate for creating bright, airy spaces. Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment

Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment

Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment Natural light can flow unhindered through the glass, reducing the need for artificial lighting during the day and contributing to a more energy-efficient environment 6mm clear float glass. In commercial settings, such as retail stores and office buildings, this feature can help create an inviting atmosphere that fosters a sense of openness and collaboration. In conclusion, understanding and implementing the concept of average replacement cost can significantly enhance a company's inventory management strategy. It provides a stable and realistic view of product costs, helping businesses to make informed decisions about their operations and financial planning. As such, it remains a valuable tool for maintaining competitiveness and ensuring long-term success in an ever-changing marketplace. In conclusion, 3mm float glass, when precisely cut to size, offers endless possibilities in design and function. Its adaptability, coupled with the meticulous cutting process, makes it a popular choice for architects, interior designers, and homeowners alike. Whether it's a sleek window pane, a minimalist mirror, or a custom glass tabletop, each piece reflects the precision, skill, and innovation that goes into every cut. So, the next time you encounter a beautifully cut piece of 3mm float glass, remember the craftsmanship and technology that brought it to life.

6mm clear float glass. In commercial settings, such as retail stores and office buildings, this feature can help create an inviting atmosphere that fosters a sense of openness and collaboration. In conclusion, understanding and implementing the concept of average replacement cost can significantly enhance a company's inventory management strategy. It provides a stable and realistic view of product costs, helping businesses to make informed decisions about their operations and financial planning. As such, it remains a valuable tool for maintaining competitiveness and ensuring long-term success in an ever-changing marketplace. In conclusion, 3mm float glass, when precisely cut to size, offers endless possibilities in design and function. Its adaptability, coupled with the meticulous cutting process, makes it a popular choice for architects, interior designers, and homeowners alike. Whether it's a sleek window pane, a minimalist mirror, or a custom glass tabletop, each piece reflects the precision, skill, and innovation that goes into every cut. So, the next time you encounter a beautifully cut piece of 3mm float glass, remember the craftsmanship and technology that brought it to life. By investing in double glazed glass units, homeowners also contribute to environmental sustainability. By reducing energy consumption, they lower the carbon footprint associated with heating and cooling a home. Energy-efficient homes are increasingly desirable, making double glazing not only a sound choice for comfort but also a responsible option for those conscious of their environmental impact.

Furthermore, aluminium framed mirrors come in a variety of shapes and sizes, making it easy to find the perfect mirror to suit your space. Whether you are looking for a large statement mirror for your living room or a small vanity mirror for your bathroom, there is sure to be an aluminium framed mirror that fits your needs

aluminium framed mirror.

In addition to their aesthetic appeal, silver textured mirrors also have practical benefits

. The reflective surface of these mirrors can make a room feel larger and more open, making them a great choice for small spaces. They can also be used to create the illusion of depth in a room, making them a versatile design element that can enhance any space.Glazed Tempered Glass A Versatile and Safe Material The use of dark grey floating glass as a design feature is more than just an aesthetic choice; it's a statement on the intersection of form and function. The dark grey hue provides a neutral yet powerful backdrop that can either fade into the background or serve as a focal point, depending on the designer's intent. Its versatility is unmatched, making it suitable for both residential and commercial settings. When it comes to maintenance, black aluminum mirrors are relatively low-maintenance The appeal of float glass mirrors lies not only in their optical clarity but also in their versatility. They can be cut, shaped, and tempered to suit various design requirements. Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities

Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities

Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities Whether it's a sleek, frameless bathroom mirror or a intricately designed, beveled wall mirror, float glass offers endless possibilities float glass mirror. Moreover, these mirrors have excellent thermal stability, making them suitable for areas with fluctuating temperatures.

float glass mirror. Moreover, these mirrors have excellent thermal stability, making them suitable for areas with fluctuating temperatures. Exploring Float Glass Designs A Perfect Blend of Functionality and Aesthetics

The market for pattern glass is evolving rapidly, driven by technological innovations and changing consumer preferences. Advances in glass manufacturing techniques have enabled suppliers to create increasingly intricate designs while maintaining affordability and accessibility. Innovations such as 3D printing and enhanced glass treatments allow for customization that once seemed impossible, providing endless possibilities for designers looking to make a statement.

Check the connection between the beam and the column.

Glass, a remarkable material with a history dating back thousands of years, continues to fascinate us with its versatility and aesthetic appeal. The term float glass specifically refers to a type of flat glass produced using the float process, where molten glass is floated on a bed of molten tin to create uniform thickness without the need for grinding and polishing. However, beyond float glass, there exists a fascinating world of different glass types, each with unique properties and uses.Self Frosting Glass A Closer Look at Innovation in Design and Functionality

The Silver Gothic Mirror has a magnetic quality that draws people in, inviting them to explore its depths 8mm float glass refers to a thickness of 8 millimeters, which strikes a perfect balance between strength, durability, and optical clarity. The manufacturing process involves melting raw materials like silica sand, soda ash, and limestone in a furnace at temperatures exceeding 1700°C. The molten glass is then poured onto a bed of molten tin, where it floats and spreads evenly to achieve a perfectly flat surface. As it cools, the glass solidifies, and subsequent annealing ensures internal stresses are relieved, enhancing its structural integrity. Once the glass pane is formed, it is carefully cleaned and polished to ensure that the surface is smooth and free of any imperfections. This is crucial for a mirror to provide a clear and accurate reflection. The next step is to apply a thin layer of metal, usually aluminum or silver, to the back of the glass pane. This reflective coating is what allows the mirror to reflect light and images This reflective coating is what allows the mirror to reflect light and images

This reflective coating is what allows the mirror to reflect light and images This reflective coating is what allows the mirror to reflect light and images

This reflective coating is what allows the mirror to reflect light and images This reflective coating is what allows the mirror to reflect light and images mirror pane glass. In addition to these fundamental considerations, environmental responsibility is becoming an increasingly significant factor for many businesses. Reflective glass suppliers who prioritize sustainability by employing eco-friendly practices and sourcing materials responsibly may gain a competitive edge in the market. Bamboo Mirror Silver Another advantage of ultra clear glass is its durability

mirror pane glass. In addition to these fundamental considerations, environmental responsibility is becoming an increasingly significant factor for many businesses. Reflective glass suppliers who prioritize sustainability by employing eco-friendly practices and sourcing materials responsibly may gain a competitive edge in the market. Bamboo Mirror Silver Another advantage of ultra clear glass is its durability In addition to energy efficiency and sustainability, Low-E2 glass offers enhanced durability and performance. The coating on Low-E2 glass not only improves insulation but also serves as a protective layer, reducing the accumulation of dirt and grime. This self-cleaning property lessens maintenance requirements, making it an appealing option for high-rise buildings and hard-to-reach areas.

When it comes to home maintenance, one of the key aspects that often gets overlooked is window replacement. Windows play a crucial role in the overall look and functionality of a house, and neglecting to replace them when necessary can lead to a range of issues. One popular option for window replacement is IGU (Insulated Glass Unit) windows. Acid-etched glass, also known as frosted glass, is a versatile and elegant material that has found its way into various applications in architecture, interior design, and art. Its unique texture and translucent appearance are achieved through an intricate process involving acid treatment. This has led to a thriving industry of acid-etched glass suppliers, each offering their own distinctive products and services. Crafted with meticulous attention to detail, the wave pattern glass is made by skilled artisans who pour molten glass into molds, creating a base layer. Then, they carefully apply layers of different colored glass on top, using techniques such as fusing and slumping to achieve the desired wave-like patterns. Each layer is carefully monitored to ensure that the colors blend seamlessly, creating a harmonious and visually stunning effect. And so, the bronze mirror, low in profile yet high in significance, continued to captivate all who encountered it. Its glass, once merely a tool for self-reflection, now acted as a portal to a world long gone, offering glimpses of grandeur and simplicity alike. In this small corner of the marketplace, the bronze mirror stood as a testament to the enduring mystery and majesty of the past, beckoning all who yearned to know more about the generations that had come before them.

Float Glass Sheets An Overview of Their Characteristics and Applications

In the soft light of summer evenings, the mirror serves as a quiet retreat for introspection. It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation

It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation

It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation It reflects the gentle flames, casting a soothing radiance that invites deep thoughts and peaceful contemplation silver mirror over fireplace. It's a place where one can find solace, gazing into the depths of their own reflection, lost in the tranquility of the moment.

silver mirror over fireplace. It's a place where one can find solace, gazing into the depths of their own reflection, lost in the tranquility of the moment. Once you've found the ideal glass for sale, proper care is essential to maintain its beauty. Most glassware is dishwasher safe, but it is wise to check the manufacturer’s recommendations. Hand washing delicate pieces can prolong their life and maintain their shine. When storing, use soft cloths to prevent scratches and avoid stacking heavy items on top.

- Shower Enclosures In bathrooms, tempered insulated glass is ideal due to its safety qualities and resistance to temperature changes.

The Enigma of Thin Mirror Glass In conclusion, frosted brown glass is a versatile and stylish design element that can add beauty and sophistication to any space. Its privacy-enhancing properties, luxurious appearance, and versatility make it a popular choice for those looking to elevate their interior design. Whether used in windows, doors, or as a decorative accent, frosted brown glass is sure to make a statement in any room. * Customer service Choose a supplier that provides excellent customer service, including prompt delivery, responsive technical support, and easy returns or exchanges. At night, the magic intensifies. The tinted black glass windows transition from being mere reflective surfaces to becoming screens onto which the city's neon dreams are projected. They shield the interiors from the bustling world outside while still allowing those within to enjoy the spectacle of urban nightlife. The glass acts like a veil, creating an intimate sanctuary where one can observe without being observed.

- Commercial Displays Retailers often use tinted tempered glass in displays to protect merchandise from UV light while maintaining visibility to customers.

They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver

They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver They offer a glimpse into one's own reflection, yet present it through a lens tinted by the rich history and cultural significance of silver sterling silver mirrors. One cannot help but contemplate the depth of character captured in the reflection of a sterling silver mirror—an intersection of personal identity and timeless luxury. Laminated mirror glass is a type of safety glass that consists of two or more layers of glass bonded together with a layer of plastic interlayer. This interlayer, usually made of polyvinyl butyral (PVB), acts as a barrier that prevents the glass from shattering into dangerous fragments when it is subjected to impact or stress. In addition to its practical benefits, tinted glass can also add a decorative element to your space. With a wide range of colors to choose from, you can easily complement your existing decor or create a bold statement with a pop of color

sterling silver mirrors. One cannot help but contemplate the depth of character captured in the reflection of a sterling silver mirror—an intersection of personal identity and timeless luxury. Laminated mirror glass is a type of safety glass that consists of two or more layers of glass bonded together with a layer of plastic interlayer. This interlayer, usually made of polyvinyl butyral (PVB), acts as a barrier that prevents the glass from shattering into dangerous fragments when it is subjected to impact or stress. In addition to its practical benefits, tinted glass can also add a decorative element to your space. With a wide range of colors to choose from, you can easily complement your existing decor or create a bold statement with a pop of color

tinted glass colour. Tinted glass is also versatile and can be used in a variety of settings, from modern and sleek to traditional and elegant. However, it's important to note that the choice of tinted glass depends on factors such as location, orientation, and climate. In colder regions, for instance, a lighter tint might be preferred to allow for more natural light and warmth. Therefore, careful consideration and planning are essential in utilizing tinted glass effectively. Apart from privacy, tinted glass also offers several aesthetic benefits