Links:

-

In construction, wire mesh is an indispensable component. Reinforced concrete structures often incorporate wire mesh to enhance their structural integrity, preventing cracks and increasing durability. It's also widely used in flooring, roofing, and wall reinforcement. Its ability to withstand high stress and provide stability makes it ideal for these applications.

The Evolution and Significance of Pipe Machines

One of the primary reasons for the preference of steel water tanks over other materials like plastic or fibreglass is their longevity and resistance to environmental conditions. Steel tanks, especially those made from stainless steel or galvanized steel, offer an excellent balance between weight and strength. The price of a 1000 litre steel water tank, therefore, is largely influenced by the type of steel used. Stainless steel tanks are typically more expensive due to their corrosion resistance and health safety features, making them a preferred choice for potable water storage.

One of the most significant advantages of the 18/20 gauge black annealed wire is its versatility. Jewelry makers use it for creating intricate pieces due to its pliability and strength. It holds shapes well and is ideal for weaving or stringing beads. Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties

Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties

Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties Additionally, electronic hobbyists find this wire perfect for prototyping and building circuits because of its electrical conductivity and insulating properties 18 gauge black annealed wire. One of the primary benefits of galvanized iron wire coil is its resistance to rust and corrosion. The process of galvanization involves coating the iron wire with a layer of zinc, which creates a protective barrier that prevents moisture and other corrosive elements from reaching the underlying metal. This makes galvanized iron wire coil particularly well-suited for outdoor use, where it may be exposed to the elements.

18 gauge black annealed wire. One of the primary benefits of galvanized iron wire coil is its resistance to rust and corrosion. The process of galvanization involves coating the iron wire with a layer of zinc, which creates a protective barrier that prevents moisture and other corrosive elements from reaching the underlying metal. This makes galvanized iron wire coil particularly well-suited for outdoor use, where it may be exposed to the elements. Diverse Applications

The interplay between Chinese and German fiberglass mesh factories highlights important trends in global trade. While China offers competitive pricing and a vast array of product options, Germany provides unmatched quality and reliability. As a result, international buyers often find themselves navigating the trade-offs between cost and quality.

Concrete reinforcement wire mesh, often referred to simply as “wire mesh,” consists of a grid-like structure made from steel wires that are welded together at regular intervals. The mesh is available in various sizes and configurations, suitable for different applications. This reinforcement method is essential for distributing loads and reducing the risk of cracking, thereby extending the lifespan of concrete structures.

In addition to traditional roofing, these nails are also popular in the installation of roof insulation and vapor barriers, contributing to energy efficiency in buildings. Contractors and builders appreciate the reliability of rubber head umbrella roofing nails, making them a preferred choice in many roofing specifications.

Pultrusion is a process for producing linear fiber-reinforced plastic (FRP) composite profiles with a uniform cross-section. The pultrusion machine reinforces the fiber by impregnating them in a resin bath and then pulls it through a heated die in which the curing occurs.

The control systems on the annealed iron wire construction making machine ensure that the annealing process is carried out accurately and efficiently. They monitor and adjust the temperature, speed, and other variables to ensure that the wire is annealed properly and meets the required specifications. This level of precision and control is essential for producing high-quality iron wire that is strong, durable, and reliable for construction applications.

Overall, roofing nails factories play a vital role in the construction industry by supplying high-quality, durable fasteners for roofing projects of all sizes. With their advanced technology, production capacity, and focus on quality control and efficiency, these factories are essential partners for contractors and builders in the construction sector. Whether it's a small residential project or a large commercial development, roofing nails factories provide the necessary fasteners to ensure that roofs are securely installed and built to last.

In conclusion, the Concrete Nail Factory exemplifies the critical role of specialized manufacturing in the construction industry. By producing high-quality concrete nails that meet the diverse needs of builders and contractors, the factory underpins the structural integrity of our built environment. As construction projects become more ambitious and sophisticated, the products of the Concrete Nail Factory will continue to play an essential role in transforming blueprints into reality. With a focus on quality, sustainability, and innovation, the factory not only contributes to the present but also helps shape a more resilient future for the construction industry.

1. Material Quality The cost of the raw materials used to manufacture the nails significantly affects their price. High-quality steel and galvanization processes ensure durability and resistance to rust, which are crucial for roofing applications. Suppliers that prioritize quality may charge higher prices, but these costs can translate into long-term savings through improved longevity of the roofing system.

china umbrella roofing nails pricelist

One way to determine the price of hexagonal wire netting is to consult a pricelist from a reputable supplier. A pricelist will typically provide pricing information for different sizes and types of hexagonal wire netting, making it easy to find the right product for your needs. It is important to keep in mind that cheaper does not always mean better, so be sure to consider the quality and durability of the wire netting as well.

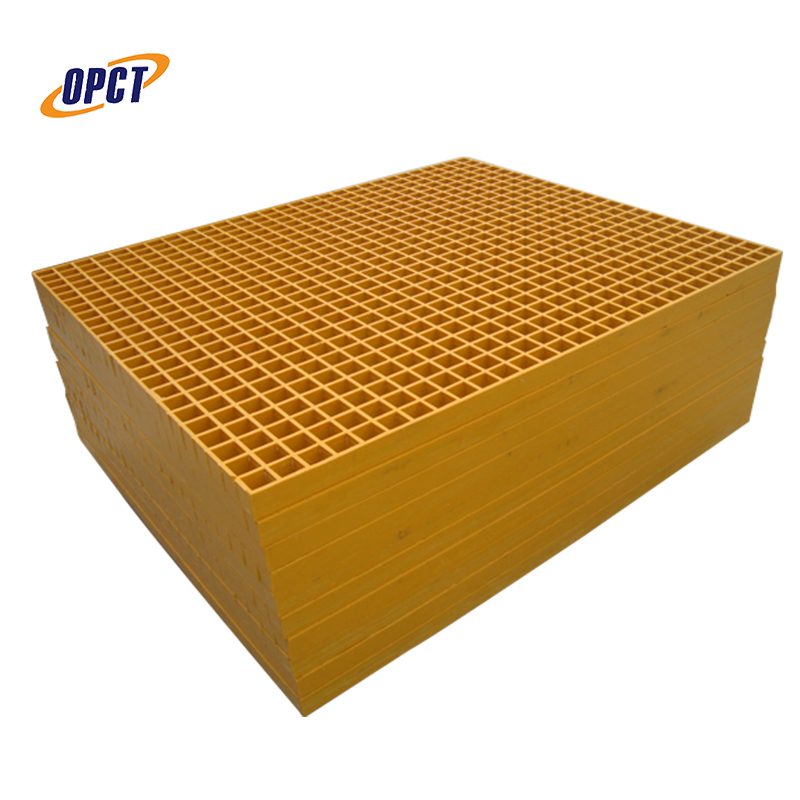

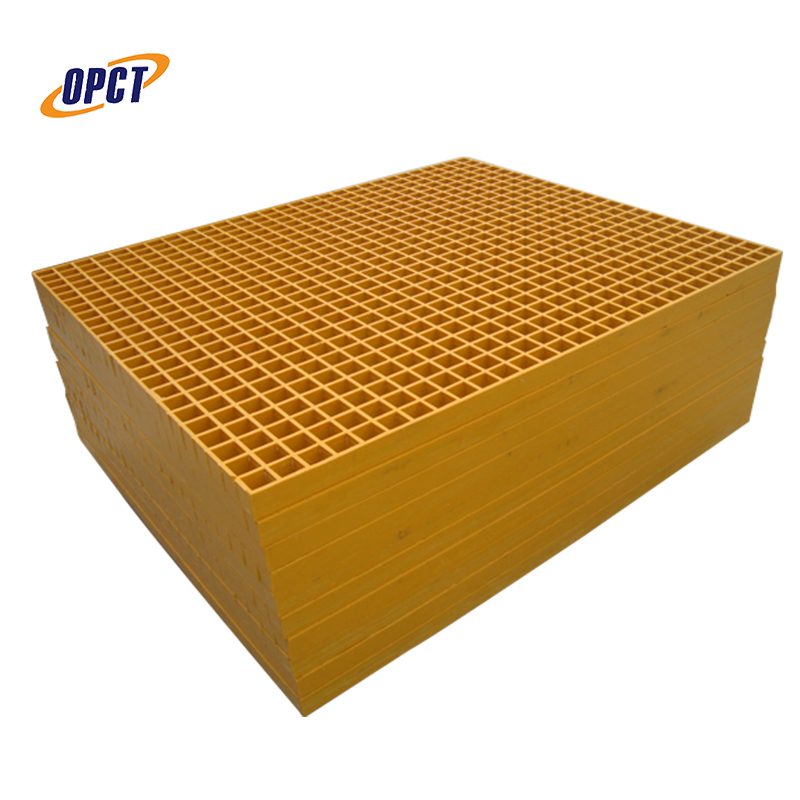

Some common applications of fiberglass grating include industrial flooring, walkways, platforms, and stair treads. In the food processing industry, where hygiene and safety are paramount, fiberglass grating can be used in areas requiring easy cleaning and maintenance. Additionally, it is frequently utilized in marine applications, such as docks and piers, where water exposure is a constant concern.

In conclusion, barbed wire rolls remain a go-to solution for both agricultural and industrial fencing needs. Their versatility, coupled with careful selection based on purpose, environment, and legal considerations, makes them an enduring choice for those seeking secure and reliable fencing solutions. Whether you're a farmer looking to protect your livelihood or a business owner aiming to secure your assets, barbed wire rolls for sale offer a practical and effective answer to a wide range of challenges. In conclusion, China steel coil plays a vital role in various industries, providing essential materials for automotive, construction, energy, manufacturing, and consumer goods sectors. With its strong manufacturing capabilities and high-quality standards, China has become a leading producer and exporter of steel coil products in the global market. As demand for steel coil continues to grow, China's reliable and versatile products will remain essential components in the development of modern industries. In the world of hobbyists and DIY enthusiasts, the 1/8 inch fiberglass rod is a staple. It is commonly used in model building, serving as structural support or decorative elements within scale models of vehicles, ships, and aircraft. The rod's ability to bend without breaking allows for precise shaping, while its smooth finish ensures a professional look upon completion.

Installation Process

750 gallon fiberglass septic tank

In today's world, where water scarcity is becoming increasingly prevalent, the need for effective water storage solutions is more critical than ever. Custom steel water tanks are emerging as one of the most reliable and versatile methods for storing water. These tanks offer numerous benefits that make them an ideal choice for various applications, including agricultural, industrial, and residential uses.

There are several types of pipe machines, each tailored for specific purposes. One of the most common is the pipe bending machine, which allows for the precise shaping of pipes into desired angles and curves. This is essential in applications where pipes must navigate complex routes without compromising functionality.

When it comes to woodworking and construction, the details often make the difference between a good project and a great one. One of the most important components in achieving that level of finesse is the type of fasteners used. Among these, 2D finish nails have gained recognition for their versatility and ability to provide a seamless finish. In this article, we will explore what 2D finish nails are, their applications, and how to use them effectively in your woodworking projects.

Furthermore, fiberglass tubes are non-conductive and non-corrosive, making them suitable for use in electrical and marine applications. Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability 2 inch fiberglass tube.

2 inch fiberglass tube. 1. Strength and Durability The primary advantage of crimped woven wire mesh is its strength. The crimped wires create a cross-section that allows the mesh to handle heavy loads without deforming or breaking. This makes it particularly suitable for industries that utilize crushers and screens where heavy materials are present.

The 500-gallon capacity is perfect for a range of applications. For homeowners, it can serve as an efficient water storage solution for irrigation, livestock, or even potable water systems with proper treatment protocols. In agricultural settings, these tanks are invaluable for storing rainwater, which can alleviate reliance on municipal water supply and reduce costs.

Fiberglass walkway grating is an innovative solution for creating durable and safe pathways in various environments. This specialized material combines the strength of fiberglass with the practicality of grating, resulting in a product that is both aesthetically pleasing and functionally superior to traditional walkway materials.

Hygiene and Safety

stainless steel water tank rectangular

As technology continues to advance, so too does the need for reliable cable management solutions. Fibreglass cable trays represent a significant step forward in this domain, offering not just protection and organization but also peace of mind. From busy manufacturing plants to sprawling corporate buildings, these trays ensure that the lifeline of modern industry—its cables and wires—are secure, organized, and efficient. The robust nature of heavy gauge welded wire mesh makes it an ideal choice for environments where strength and longevity are paramount. It is frequently used in construction sites to create barriers or safety fences, preventing accidents and ensuring the security of the premises. Its ability to withstand harsh weather conditions also makes it suitable for outdoor use, such as in parks or along highways, where it can serve as a protective barrier against wildlife or stray debris. In conclusion, wire nails are a versatile and essential item for anyone involved in woodworking, construction, or DIY projects. When shopping for wire nails for sale, it is important to consider the material, size, length, and head type of the nails to ensure you choose the right ones for your project. By taking the time to select the right wire nails, you can ensure a strong and durable hold for your next project.

Iron wire is available in various forms and specifications. Some of the most common types include

Production Processes

Another significant advantage of 80-gallon stainless steel tanks is their ability to be customized. Depending on the specific needs of a business, these tanks can be manufactured with varying features such as insulation, additional ports for sampling, or specialized drainage systems. Customization allows businesses to optimize their processes, whether incorporating a pressure relief valve for brewing operations or integrating a temperature control system for food storage.

5. Customizability GRP cable ladders can be custom-designed to meet specific requirements based on load capacities, dimensions, and environmental conditions. This versatility ensures they can be integrated into a wide range of projects seamlessly.

One of the most popular types of razor wire is wholesale razor wire. This type of razor wire is often sold in bulk quantities to businesses, government agencies, and other organizations that require large amounts of fencing material for security purposes. Wholesale razor wire is typically more affordable than purchasing individual coils of razor wire, making it a cost-effective option for those in need of a large amount of fencing material.

2. Cost Issues

5. Competition The competitive landscape among manufacturers and suppliers influences pricing strategies. Because China is a leading producer of construction materials, numerous suppliers vie for market share, which can lead to competitive pricing. Buyers should assess multiple suppliers and their offerings to find the best balance between price and quality.

1. Material Quality The price of a stainless steel water tank largely depends on the quality of the stainless steel used. There are different grades of stainless steel, such as 304 and 316, with 316 being more resistant to corrosive environments. Tanks made from higher-quality stainless steel usually come at a premium due to their increased durability and longer service life.

In conclusion, while the notion of a 50,000% 20-gallon tank may currently reside in the realm of hypotheticals, it serves as a symbol of hope and innovation in the pursuit of solving the global water crisis. As we continue to face the consequences of climate change and population growth, the development and adoption of groundbreaking technologies will be key to ensuring water security for generations to come.

5. Signage and Displays

1. Construction Industry In construction, binding galvanized wire is extensively used for tying rebar (reinforcing bar) and securing building materials. Its strong binding capability ensures that structures remain stable and resilient during the construction process. Additionally, it is also utilized for forming shapes and frameworks in concrete applications.

Another key advantage of fiberglass products is their cost-effectiveness. While fiberglass materials may have a higher upfront cost compared to some traditional materials, their long lifespan and low maintenance requirements make them a cost-effective choice in the long run.

fiberglass products

Quality assurance is another crucial aspect of China's finishing nails industry. Many manufacturers have adopted international quality standards, earning certifications such as ISO 9001. This focus on quality enhances the overall credibility of Chinese products and reassures international buyers about their reliability and performance. Regular inspections and adherence to strict production protocols further ensure that the finishing nails produced meet or exceed customer expectations.