Links:

-

Another field where 10mm fiberglass rod shines is in the aerospace industry

Applications of Fiberglass Rod Stock

Firstly, materials greatly impact the price of sink plates. Common materials include stainless steel, porcelain, granite, and composite sinks. Stainless steel is often favored for its durability and modern appearance, typically falling within a mid-range price bracket. Porcelain sinks, while elegant and easily cleanable, can be more expensive due to the cost of manufacturing and their susceptibility to chipping. Granite sinks are highly sought after for their natural beauty and durability; however, they usually come with a higher price tag due to the cost of extraction and processing. Composite sinks, made from a blend of materials, offer an alternative that is both stylish and resilient, with prices that can vary significantly based on the specific blend used.

One of the key characteristics of black steel iron wire is its robustness. The low carbon content allows for a degree of flexibility while maintaining a high tensile strength, making it suitable for construction projects that require reliable materials. Builders often use black steel wire in reinforcing concrete structures. The wire can be woven into mesh to provide additional support, ensuring durability and stability of buildings, bridges, and other constructions. This ability to enhance structural integrity makes black steel wire indispensable in modern engineering.

It’s essential to factor in the costs of installation when budgeting for a fibreglass water tank. While some tanks can be installed manually, larger and more complex tanks often require professional installation. Installation costs vary significantly based on location, accessibility, and the complexity of the setup. These costs can range from $300 to $1,500 or more, adding to the overall investment in a fibreglass water tank.

Craftsmen and hobbyists have also found innovative uses for plastic coated iron wire. Whether used in DIY projects, floral arrangements, or even art installations, this material aids in delivering creative freedom while maintaining integrity. Its ease of manipulation and availability in various colors make it a popular choice for both professional artists and amateurs.

Grating supplier is a crucial partner in the construction industry, providing essential materials for a variety of structural applications. From industrial platforms to walkways and stair treads, grating plays a key role in ensuring safety and stability in various environments.

The price of a 1500-litre steel water tank can vary widely depending on several factors, including the quality of the steel, the manufacturer, and any additional features that might be included. On average, you can expect to pay between $800 to $1,500. This price range is influenced by the thickness of the steel, the type of coating (such as galvanization), and the overall design of the tank. Manufacturers that provide warranties and superior customer service may also charge a premium for their products.

steel water tank 1500 ltr price

- Water Treatment These tanks are suitable for storing potable water and wastewater due to their structural integrity and safety standards, making them a reliable option for municipalities and industries.

The industrial sector also heavily relies on wire mesh The Versatile Steel Storage Tank A Modern Marvel in Industrial Solutions In terms of installation, a 1000 liter steel water tank requires professional handling due to its weight and size. This might entail additional expenses for delivery and setup. Nonetheless, many suppliers offer comprehensive packages that include installation, which can simplify the process and potentially reduce overall costs by avoiding separate charges for these services. Galvanized iron wire coil is a versatile and commonly used product in various industries. It is known for its strength, durability, and resistance to corrosion, making it an ideal choice for a wide range of applications. Overall, SS tanks for sale are an excellent choice for businesses in need of reliable storage solutions. Their durability, versatility, efficiency, and ease of maintenance make them a valuable asset for a wide range of industries. Whether you need to store water, chemicals, fuel, or other substances, SS tanks can provide a safe and secure storage solution that will meet your needs for years to come. Another aspect that sets Chinese corrugated roofing nails apart is the emphasis on quality control. Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability

Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability

Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability Manufacturers implement rigorous testing protocols to ensure that each nail meets specifications for dimensions, strength, and durability china corrugated roofing nails. This attention to detail is crucial for maintaining the integrity of roofing structures and protecting against leaks or failures under adverse weather conditions.

china corrugated roofing nails. This attention to detail is crucial for maintaining the integrity of roofing structures and protecting against leaks or failures under adverse weather conditions. 2x4 Welded Wire Mesh The Ideal Choice for Various Applications

Overall, fiberglass cooling towers offer a range of benefits for industries that require efficient heat dissipation. By partnering with a reputable manufacturer, businesses can ensure that they receive a durable, reliable, and energy-efficient cooling tower that will enhance their operations for years to come. With the right cooling tower in place, businesses can increase productivity, reduce energy costs, and maintain optimal operating conditions.

Moreover, the introduction of computer-aided design (CAD) and simulation technologies is impacting how manufacturers develop and refine their machines. These tools enable precise optimization of the pultrusion process, allowing for faster prototyping and higher-quality end products.

Versatility

Nylon window screen factories are also increasingly adopting sustainable manufacturing practices. By using eco-friendly materials and processes, these factories aim to reduce their environmental footprint while delivering superior products. This commitment to sustainability resonates with consumers who are increasingly aware of their ecological impact.

Benefits of Using Roofing Wire Mesh When working with an IPE 100 steel beam factory, communication is key. Make sure you clearly communicate your project specifications and requirements to the factory, so they can produce beams that meet your needs. Additionally, a factory that is responsive and communicative throughout the production process will help ensure that your project stays on track and on schedule.

3. Ease of Use Electro-galvanized nails are designed for ease of driving into concrete. They typically feature a sharp point and a strong shaft, enabling them to penetrate hard surfaces efficiently. This ease of installation can save time and labor costs on construction sites.

Using 2D finish nails effectively requires some specific techniques. First, it’s essential to ensure that your nail gun or hammer is set to the correct pressure to avoid driving the nails too deep. Over-sinking finish nails can create unsightly dings and may require additional work for repair. The nails should ideally be sunk just below the surface of the wood, allowing for the possibility of filling in the hole with wood filler for a smoother finish.

Fiberglass septic tanks are also known for their corrosion resistance. Unlike metal tanks that can rust over time, fiberglass tanks are inert to chemicals and do not deteriorate in acidic environments. This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements

This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements

This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements This ensures that the tank will remain in optimal condition for many years, reducing the need for costly repairs or replacements fiberglass septic tank manufacturers.

fiberglass septic tank manufacturers. The primary advantage of using fiberglass rods, whether at 3% or 4%, lies in their corrosion resistance. Unlike metal rods, fiberglass does not rust or corrode when exposed to moisture or chemicals, which significantly increases its longevity, especially in applications such as marine environments or chemical processing industries.

3 4 fiberglass rod

2

20 gauge 5kgs coil 7kgs coil galvanized iron wire. Gardening Trellises, stakes, and plant supports are made from galvanized iron wire to withstand weather conditions and support plants effectively.

20 gauge 5kgs coil 7kgs coil galvanized iron wire. Gardening Trellises, stakes, and plant supports are made from galvanized iron wire to withstand weather conditions and support plants effectively. Pure iron nails are an often-overlooked yet critical component in numerous industries, known for their unique properties and versatility. The factories dedicated to their production play a vital role in harnessing the potential of this material, contributing to economic growth while meeting the evolving needs of the construction and artistic sectors. As sustainability becomes increasingly important, the importance of pure iron nails is likely to rise, promising an enduring place for them in our infrastructures and practices. The future of pure iron nail production not only rests on technological advancements but also on the commitment to environmentally friendly manufacturing processes.

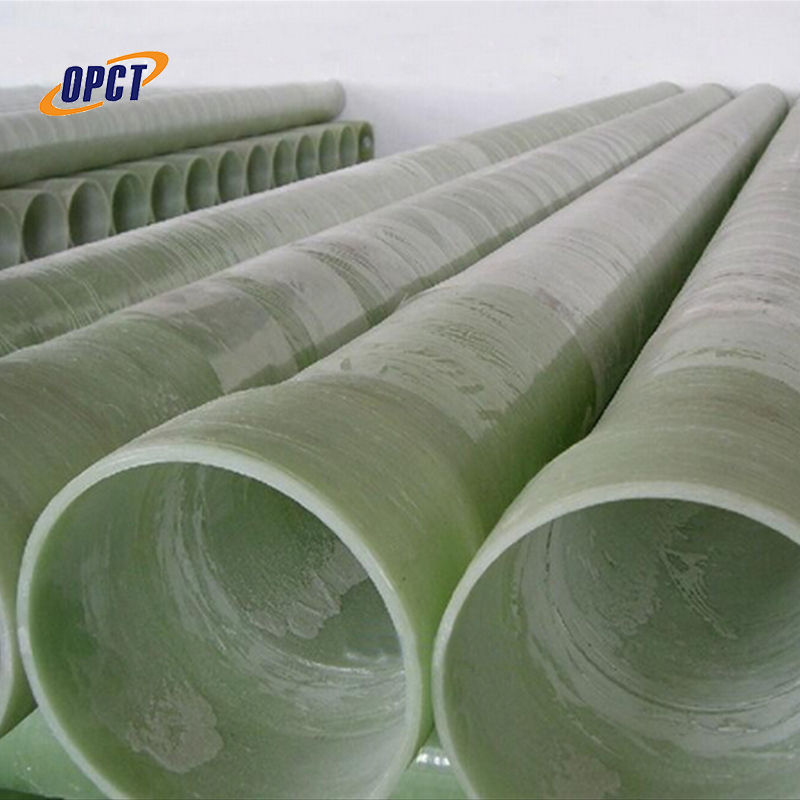

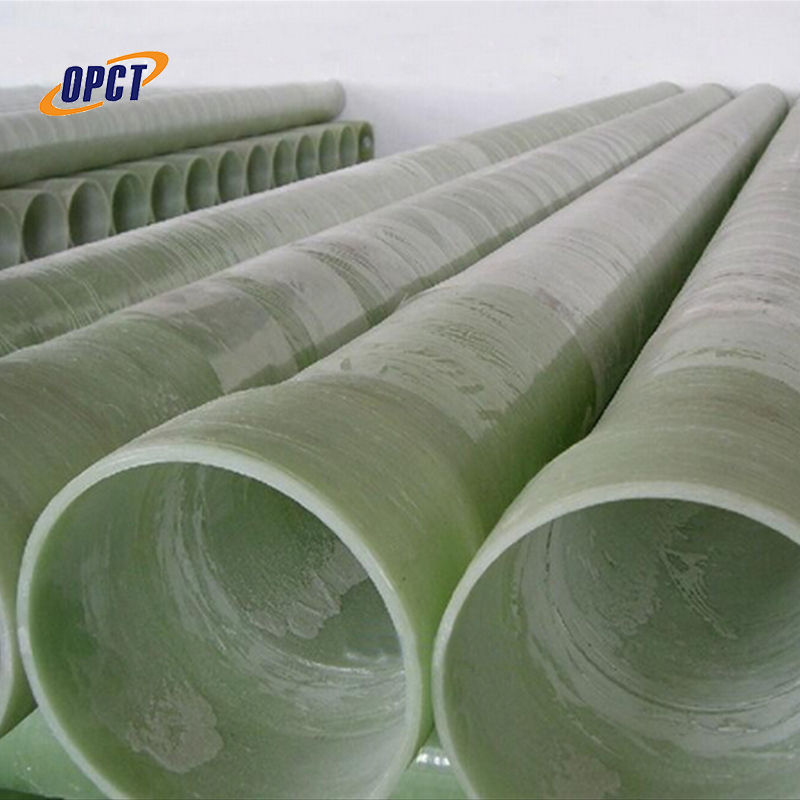

2. Lightweight and Easy to Handle The lightweight nature of FRP pipes makes them easier to transport and install compared to traditional materials like steel or concrete. This characteristic is particularly advantageous in remote areas where quick installation is essential.

PVC welded wire mesh is produced by welding together parallel and perpendicular wires to create a grid-like pattern. The welding process ensures that the connections are strong and secure, providing high structural integrity. After welding, the mesh is coated with PVC, which not only enhances its longevity but also adds a layer of protection against various elements. The thickness of the wire and the size of the mesh openings can be customized according to specific requirements, making it suitable for a wide range of applications.

Understanding Square Wire Mesh

In the world of storage solutions, the 50% 20-gallon stainless steel water tank stands out as a testament to both functionality and durability. This tank, with its sleek stainless steel exterior, offers not only a modern aesthetic but also a level of utility that makes it an indispensable asset for various applications. Today, we may no longer rely on square boats with nails factories to sustain our economies or expand our horizons. But we do still look to the past for inspiration and guidance, drawing on the lessons learned from those who came before us. And as we face new challenges and opportunities in our own time, we can take comfort in knowing that the same spirit of adventure and discovery that propelled those early vessels across the waves still burns bright within us all.

Composition and Properties

As a Catalyst:

A stainless steel water tank is a practical and durable solution for storing and transporting water in various settings

. With a capacity of 20 gallons, this type of tank can hold a significant amount of water for use in homes, businesses, and even in emergency situations.- Stainless Steel Wire Mesh $0.50 - $5.00/sq ft

Once the nails are formed and textured, they are then subjected to a series of quality control checks to ensure they meet the required standards. This includes checking the dimensions, weight, and strength of the nails. Any nails that do not meet the specified criteria are discarded, and only the highest quality nails are packaged and shipped to customers.

In conclusion, a 500-gallon galvanized water tank is an excellent investment for anyone in need of a reliable and durable water storage solution. Its longevity, versatility, cost-effectiveness, aesthetic appeal, and safety make it a standout choice for agricultural, commercial, and residential purposes. As the demand for efficient water storage continues to grow, opting for a galvanized water tank can ensure that you are making a responsible and sustainable choice for all your water storage needs. Whether for irrigation, livestock, or other applications, a 500-gallon galvanized tank is a smart option that will serve you well for many years to come.

Mini cooling towers are essential components in many industrial and commercial settings, as well as in residential air conditioning systems. These compact and efficient devices play a crucial role in removing excess heat from various processes and equipment, ensuring smooth operation and preventing overheating.

Environmental Considerations

An electro galvanized barbed wire factory employs advanced technology and machinery to produce high-quality wire. The manufacturing process begins with the selection of high-grade steel wire, which is then cleaned and prepped for galvanization.

Wire mesh and netting are essential materials that find applications across various industries due to their versatility, strength, and durability. These materials consist of interconnected strands of wire, which can vary in size, shape, and material, making them suitable for numerous uses. From construction and agriculture to security and decorative applications, wire mesh and netting are integral components in many facets of modern life.

2. Aerospace and Automotive The aerospace and automotive industries are always in pursuit of materials that can enhance performance and fuel efficiency. 1% fiberglass tubes can be employed in components that require a balance of weight and sturdiness. For example, they may be used in the framework of vehicles or as part of aircraft interiors, where strong yet lightweight materials contribute to overall efficiency.

3% and 4% fiberglass rods find applications across multiple industries. In the construction industry, they are often used in the reinforcement of concrete structures, where their tension and compressive strengths are utilized to improve overall stability.

4. Ease of Maintenance Steel tanks are relatively easy to clean and maintain. Regular inspections and proper cleaning protocols can extend the life of the tank and ensure that stored materials remain uncontaminated.