Another aspect to consider is the economic efficiency that arises from using concrete and steel nails in building projects. While the initial investment may be higher than using alternative materials, the long-term savings in maintenance, repairs, and energy costs can be substantial. Concrete structures tend to require less maintenance than those made with less durable materials, reducing the overall lifecycle costs. The strength of steel nails also ensures a reliable hold, minimizing the risk of structural failure and associated costs.

Fiber Reinforced Polymer (FRP) is increasingly prevalent in various industries due to its remarkable properties, including high strength-to-weight ratio, excellent corrosion resistance, and durability. One critical aspect of FRP applications is the design and specification of flanges, which are crucial for effectively connecting and sealing systems in piping, tanks, or structural assemblies. In this article, we will explore the significance of FRP flange dimensions and provide insights into standard practices for dimensioning.

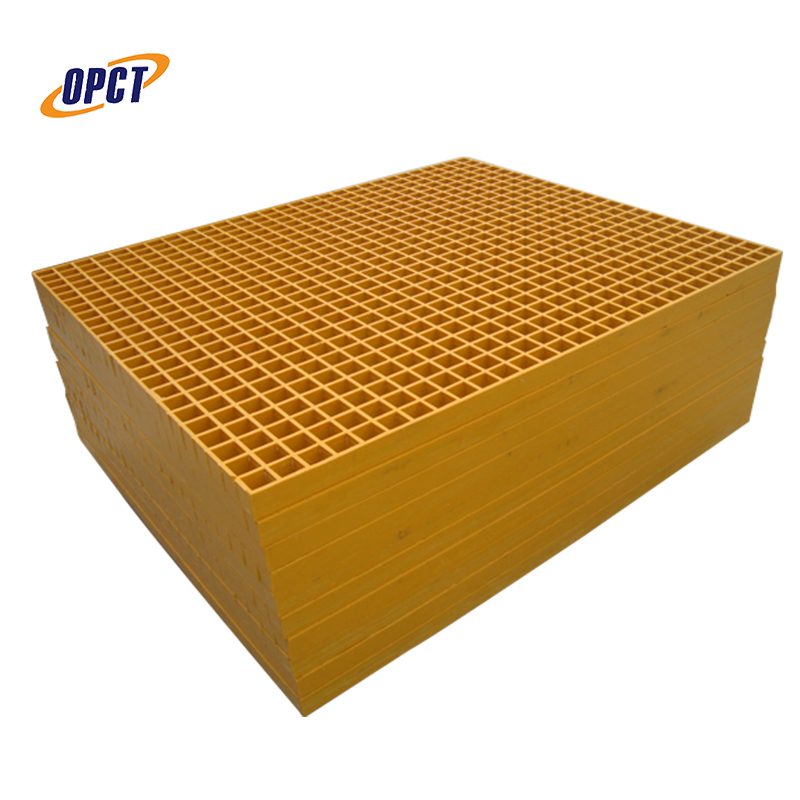

In conclusion, frp tray is a versatile and durable solution for a wide range of industrial applications. Its corrosion resistance, strength, and lightweight nature make it an ideal choice for industries that require reliable and cost-effective equipment. With its ability to withstand harsh chemical environments and heavy loads, frp tray offers long-lasting performance and peace of mind for industrial operations. If you are looking for a reliable and durable tray solution for your facility, frp tray may be the perfect choice for you.

Double twisted black annealed iron wire is produced by twisting two strands of iron wire together, with a specific annealing process that enhances its malleability and reduces brittleness. The annealing process also gives the wire a distinct black appearance due to the oxidation that occurs, which can provide additional corrosion resistance in certain environments. This wire is primarily used in construction, agriculture, and fencing, making it an essential product across various sectors.

Small mesh wire mesh is a remarkable material that has found its way into various industries, enhancing functionality and efficiency. Characterized by its closely spaced strands, this type of mesh provides numerous advantages across a range of applications, making it an essential component for construction, agriculture, manufacturing, and more.

As we look towards the future, the focus on sustainability within the beauty industry is also affecting nail care. Eco-friendly nail products, which are free from harmful chemicals, are gaining traction among consumers concerned about their health and the environment. Brands are developing polishes that are cruelty-free, vegan, and made from non-toxic ingredients, thus making a responsible choice without compromising on style.

Square wire mesh fencing has become a popular choice across various applications due to its versatility, durability, and aesthetic appeal. This type of fencing consists of rectangular or square wire openings, which can be made from various materials, including galvanized steel, stainless steel, and even plastic coatings. As security needs evolve and design preferences change, square wire mesh fences offer an effective solution suitable for both residential and commercial environments.

The fiberglass production process begins with raw materials, primarily silica sand, alumina, and various additives. These materials undergo a melting process at extremely high temperatures, typically around 1,400 to 1,600 degrees Celsius. The melted glass is then formed into fibers using several methods, including the traditional plunge method and more advanced techniques like the blow method. The choice of method often depends on the desired fiber diameter and application.

Black steel nails are made from carbon steel, which is known for its strength and durability. The term black refers to the finish of the nails, which is a result of the manufacturing process that leaves a protective layer of iron oxide. This finish provides an aesthetic appeal and also enhances the nails' resistance to corrosion to some extent. However, it is important to note that while this protective layer aids in resisting rust, these nails are not fully rust-proof. Therefore, their use is best suited for indoor applications or in environments where they will not be exposed to excessive moisture.

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability

Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability Whether used as insulating sleeves for electrical wires or as structural components in boat building, the 2-inch fiberglass tube offers reliable performance and long-lasting durability