Links:

In environments such as commercial buildings, schools, hospitals, and public transportation facilities, the use of stair nosing is not just advisable but often required by safety regulations. Additionally, residential properties benefit from these safety measures, as they provide peace of mind to homeowners, especially those with young children or elderly residents.

Another significant advantage is the low maintenance requirement of FRP grating. Unlike traditional materials that may require regular painting or treatment to prevent rusting and degradation, FRP is inherently resistant to such issues. As a result, companies can enjoy lower lifecycle costs and reduced downtime for maintenance.

4. Market Demand Like any commodity, the price of FRP vessels is influenced by market demand. A sudden increase in demand for specific applications, such as wastewater treatment or coastal infrastructure projects, can drive prices up. Additionally, fluctuations in the raw material market, such as the cost of fiberglass and resin, can also affect overall pricing.

One of the most significant benefits of using 1354 FRP vessels is their exceptional resistance to corrosion. Unlike metal vessels, which can degrade over time due to chemical reactions with harsh substances, FRP vessels maintain their integrity even when exposed to aggressive environments. This makes them an ideal choice for industries such as chemical processing, wastewater treatment, and offshore oil and gas operations, where conditions can be particularly demanding.

Fiber Reinforced Polymer (FRP) channels have garnered significant attention in various sectors due to their unique properties such as high strength-to-weight ratio, corrosion resistance, and design flexibility. As industries increasingly lean towards advanced materials to enhance performance and durability, the pricing of FRP channels becomes a pivotal topic. This article delves into the factors influencing FRP channel prices, market trends, and their implications for various stakeholders.

In recent years, the demand for durable and cost-effective fencing solutions has risen dramatically. Among the various options available, Glass Reinforced Plastic (GRP) palisade fencing has emerged as a popular choice for both residential and commercial applications. This article explores the unique features and benefits of GRP palisade fencing, which make it an ideal solution for many property owners.

As the demand for greener, more sustainable infrastructure continues to rise, FRP walkways represent a forward-thinking solution that meets modern requirements for durability, design, and safety. More industries and local governments are recognizing the advantages of implementing FRP walkways as part of their investment in sustainable infrastructure for future generations. The combination of innovative material science and a commitment to environmental stewardship makes FRP walkways a leading choice for today's infrastructure projects.

The construction process of Pentair FRP tanks involves layering fiberglass with a resin that forms a strong bond, resulting in a lightweight yet robust product. This not only ensures mechanical strength but also contributes to the tank's ability to handle high internal pressures, making them ideal for applications where large volumes of water need to be stored safely. With a smooth inner surface, FRP tanks also promote better water quality by minimizing bacterial growth and reducing sediment buildup.

pentair frp tank

- Commercial Buildings Architects often utilize bar grating in staircases, outdoor dining areas, and lounges for both aesthetics and functionality

.Another effective method is water filtration, which employs physical and chemical processes to remove pollutants. Different types of filters, including activated carbon, ceramic, and UV filters, can be employed based on the specific contaminants present in well water. Activated carbon filters are effective at removing chlorine, sediment, and volatile organic compounds (VOCs), while UV filters can eliminate bacteria and viruses without the use of chemicals.

Constructed from high-quality steel, sectional steel tanks are built to withstand harsh environmental conditions, including extreme temperatures, UV exposure, and severe weather. They are often designed with corrosion-resistant coatings and protective measures, ensuring longevity and reduced maintenance costs. When properly maintained, these tanks can last for several decades, making them a reliable investment for businesses.

sectional steel tanks

Another significant benefit of stainless steel floor grating is the wide range of customization options available. Manufacturers can produce grating in various sizes, thicknesses, and patterns to meet specific project requirements. This flexibility enables businesses to create a tailored flooring solution that fits their operational needs while complying with safety regulations. Moreover, stainless steel can be easily cut and shaped, allowing for intricate designs and unique installations.

- Soil Retention For projects requiring soil retention, such as highways and railways, FRP sheet piling offers a durable and stable solution that can withstand lateral earth pressures while minimizing deformation.

3. Drainage Systems In various environments, galvanized bar grating can serve as an effective cover for drainage ditches and gutters. It helps prevent debris from clogging the drainage systems while allowing water to flow freely.

Moreover, the construction of large square water tanks can be tailored to utilize materials that enhance durability and resistance to environmental factors. Reinforced concrete, stainless steel, or even advanced composite materials can be used to build these tanks, ensuring that they can withstand the rigors of time, pressure, and storage conditions. These materials are not only robust but can also be designed to reduce energy costs associated with temperature control, providing an additional layer of advantage.

large square water tanks

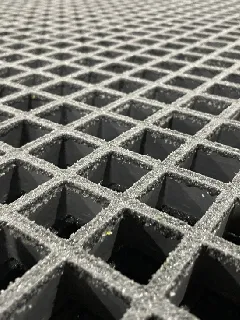

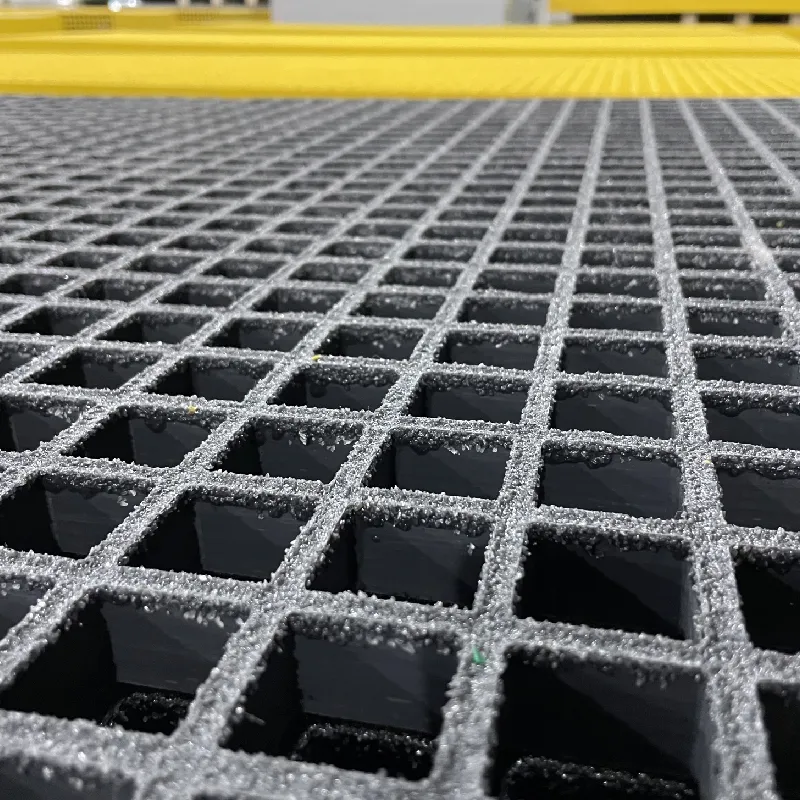

What is FRP Grating?

Moreover, the flexibility of FRP allows for the fabrication of complex shapes and profiles, accommodating various design requirements. This characteristic proves invaluable in architectural applications where aesthetic considerations and innovative designs are paramount. Additionally, FRP can be customized with different fiber types and orientations to meet the specific strength requirements of a project.

In industrial applications, aluminum bar grating excels in manufacturing plants, refineries, and chemical processing facilities, where durability and resistance to harsh chemicals are critical. The lightweight nature of aluminum also aids in compliance with weight restrictions, which can be particularly crucial in facilities that rely on overhead lifting systems or where weight-bearing capabilities are a concern.

Conclusion

- Drainage Covers The open design of FRP grating allows for smooth drainage in areas prone to water accumulation, helping to prevent hazardous conditions.

Durability

What is Fiberglass Grating?

In conclusion, Glass Fiber Reinforced Polymer rebar represents a significant advancement in construction technology. With its corrosion resistance, lightweight properties, high tensile strength, and compatibility with concrete, GFRP rebar offers an attractive alternative to traditional steel reinforcement. As the industry embraces these modern solutions, GFRP rebar stands out as a material that can enhance the durability, safety, and sustainability of our built environment, paving the way for the structural innovations of the future.

4. Thermal Insulation FRP materials provide excellent thermal insulation, which is crucial in processes requiring temperature control. This property ensures that stored contents maintain their desired temperature, improving process efficiency and quality.

Conclusion

3. Waterjet Cutting For those requiring highly complex designs or precise cuts without the risk of heat damage, waterjet cutting is an advanced technique. This method uses a high-pressure stream of water mixed with abrasives to cut through materials, making it ideal for sensitive applications.

The Emergence of FRP Bridge Deck Panels in Modern Infrastructure

Another significant advantage of FRP grating is its versatility in design and application. It is available in various sizes, colors, and load-bearing capacities, allowing it to be customized to meet specific project requirements. This adaptability makes FRP suitable for a broad range of applications, including walkways, platforms, trench covers, and industrial flooring. Moreover, FRP can be molded into various shapes, enhancing its applicability in complex architectural designs.

FRP grating is manufactured by combining fiberglass strands with a resin matrix. This process results in a composite material that exhibits exceptional tensile strength and toughness. The grating comes in various forms, including molded and pultruded options, which can be tailored to meet specific application requirements. The design typically features a grid-like structure, allowing for efficient drainage and slip resistance, making it suitable for walkways, platforms, and stair treads.

The Rise of FRP Walkways A Sustainable Solution for Modern Infrastructure

Design Specifications and Customization

Security and Privacy

1. Power Saws Tools like circular saws, jigsaws, or reciprocating saws equipped with carbide-tipped blades are commonly used for cutting FRP. These tools can cut through the dense composite material efficiently, producing clean edges when operated correctly.

The Galvanized Sectional Water Tank A Durable Solution for Water Storage

- Environment Evaluate the environmental conditions of the intended application. If exposure to chemicals or extreme weather is a concern, ensure that the chosen grating has the appropriate chemical resistance.

Versatility in Applications

fiber reinforced plastic rod

Advantages of Sectional Tanks

5. Versatility Available in a range of colors and finishes, FRP grating can be customized to suit aesthetic and functional requirements. Its adaptability allows it to be used in various applications, from decorative walkways in parks to robust industrial flooring systems.

Beyond its functional advantages, fiberglass floor grating comes in a variety of colors and designs, allowing for greater customization in visual appeal. This flexibility enables businesses to choose grating that complements their branding or enhances the aesthetic of their facilities. The ability to integrate color into the flooring system not only serves practical purposes, such as demarcation for safety, but also enriches the overall environment of the space.

Applications of FRP Pressure Tanks

Low Maintenance

Metal bar grating is a vital component in various industries, providing essential support and safety features in countless applications. With its robust construction, versatility, and efficient design, metal bar grating is an increasingly preferred choice for architects, engineers, and contractors alike.

One of the standout features of FRP mini mesh grating is its corrosion resistance. Unlike traditional metal grating, FRP does not rust or corrode when exposed to harsh chemicals, making it suitable for environments such as chemical processing plants, wastewater treatment facilities, and marine applications. Additionally, FRP is resistant to UV radiation, ensuring that it maintains its structural integrity and aesthetic appeal even when exposed to direct sunlight.

Understanding Anti-Slip Stair Treads

2. Versatility Anti-slip treads come in various materials, colors, and designs, allowing users to choose options that suit the aesthetic and functional needs of their stairs, whether they are indoors or outdoors.

The versatility of fiberglass stair treads allows them to be used in numerous applications. They are particularly popular in commercial settings such as warehouses, schools, hospitals, and shopping malls where foot traffic is frequent. Additionally, they are ideal for residential properties, especially in homes with outdoor steps, patios, or pools, where water exposure increases the risk of slips.

One of the significant advantages of galvanized steel water tanks is their longevity. Unlike plastic tanks that can degrade over time under UV exposure, galvanized steel tanks can last for decades with minimal maintenance. This longevity translates into cost savings in the long run, as there is less need for repairs or replacements. If properly maintained, these tanks can remain functional and reliable, providing safe water storage for years.

One of the standout features of galvanized sectional water tanks is their durability. The galvanization process involves coating the steel with zinc, which protects it from rust and corrosion. As a result, these tanks can withstand harsh weather conditions, making them suitable for a variety of environments. Whether exposed to extreme heat, cold, or moisture, a galvanized tank retains its integrity over time, often with a lifespan of several decades when properly maintained.

3. Thermal Insulation FRP materials possess excellent thermal insulating properties. This characteristic is particularly crucial in applications where temperature fluctuations can impact efficiency.

pentair frp vessels