Links:

The globalization of the automotive industry has also had profound effects on auto parts. Manufacturers often source components from various countries, creating a complex supply chain. International cooperation has become crucial for maintaining quality and efficiency, as companies strive to combine cost-effectiveness with cutting-edge technology. This interconnectedness allows manufacturers to benefit from advancements in materials and design, ultimately leading to better vehicles for consumers.

auto auto parts

なをうことで、にをし、することができます。これにより、やをにぎ、やのをすることができます。

Advantages of Ribbed Belts

The efficiency and performance of an automobile's engine hinge significantly on its mechanical components, with the camshaft drive toothed belt being among the most crucial. This seemingly simple part plays a critical role in synchronizing the function of various engine components, directly influencing overall engine performance, fuel efficiency, and longevity.

Importance of the Power Steering System

2. Strength Limitations While modern belts are quite durable, they may not be as strong as chains when it comes to handling extreme power outputs. This makes them less suitable for high-performance or racing applications.

One of the primary benefits of using a flat lifting belt is the enhanced safety it provides. When lifting heavy weights, the risk of injury increases significantly, particularly for the lower back. A flat lifting belt helps to stabilize the core, reducing the strain on the lumbar region. By compressing the abdominal cavity, the belt supports the spine during movements like squats and deadlifts, helping to maintain proper posture and alignment.

- Home Appliances Many household appliances, such as washing machines and dryers, utilize V-belts for efficient operation.

What is an Adjustable V Belt?

Synchroflex timing belts find applications in numerous fields. In the automotive industry, they are commonly utilized in camshaft and crankshaft drives, ensuring precise timing for engine efficiency. In manufacturing, these belts are used in conveyor systems for materials handling, while in robotics, they facilitate motion control in robotic arms and automation equipment.

2. Reduced Maintenance Timing belts generally require less maintenance compared to chains or other mechanical drive systems. They do not require lubrication and are less prone to wear, resulting in lower overall maintenance costs and longer service life.

Typically, timing belts should be replaced every 60,000 to 100,000 miles, depending on the vehicle make and model. Rather than neglecting this crucial maintenance, car owners should treat the timing belt’s upkeep with the same dedication one would have toward monitoring the passage of time in our lives, heralded by the reliable journey of the sun across the sky.

The Importance of Quality Spare Parts

In summary, the Mitsuba Belt is much more than just an accessory; it is a reflection of cultural heritage, craftsmanship, and personal expression. With its significance rooted in Japanese tradition, the belt connects generations and transcends the boundaries of time and place. As it finds its way into modern fashion while maintaining its traditional values, the Mitsuba Belt serves as a reminder of the beauty of culture and the importance of preserving it for future generations. Whether worn during a festive celebration or as part of a contemporary outfit, the Mitsuba Belt continues to tell a story of its own, connecting people through the art of craftsmanship and cultural pride.

Un autre avantage majeur est la fiabilité accrue. Les courroies serpentine sont généralement fabriquées en caoutchouc renforcé, ce qui les rend résistant à l'usure. Elles sont également plus flexibles, ce qui leur permet de s'adapter facilement aux différentes exigences du moteur. Il convient de noter qu'une courroie bien entretenue peut avoir une durée de vie significativement plus longue que les systèmes à courroies multiples.

또한, 타이는 V벨트 생산을 위한 다양한 원자재와 부품을 쉽게 구할 수 있는 특성을 가지고 있습니다. 타이는 아시아에서 중요한 고무 생산지 중 하나로, V벨트 제작에 필요한 고무 원자재를 안정적으로 공급받을 수 있습니다. 이는 타이 V벨트 산업의 성장에 긍정적인 영향을 미치고 있습니다.

v belt thailand

3. Durability and Longevity V-ribbed belts are typically made from resilient materials such as rubber reinforced with polyester or other materials. This construction allows them to withstand wear and tear, leading to a longer service life.

In summary, EPDM PK belts offer a range of characteristics that make them an excellent choice for various applications across multiple industries. Their high flexibility, temperature resistance, and durability ensure that they can withstand the rigors of both industrial and automotive environments. As technology advances and the demand for efficient, reliable power transmission continues to grow, EPDM PK belts are likely to play an increasingly significant role in enhancing performance and sustainability across diverse applications. Whether you are involved in automotive engineering, HVAC system design, or industrial manufacturing, choosing EPDM PK belts can lead to improved efficiency and longevity in your projects.

3. Timing Belts Although not technically a drive belt, timing belts are vital for synchronizing the crankshaft and camshaft. They ensure that the engine’s valves open and close at the proper times in relation to the movement of the pistons. Unlike serpentine belts, timing belts are often made of stronger materials and have more precise functions.

There are numerous benefits associated with poly flat belts that make them a preferred choice for many applications

Signs of a Failing Alternator Belt

V-belts are essential components in various mechanical systems, widely used in automotive and industrial applications. Their primary function is to transmit power between pulleys while allowing for flexibility and dynamic response to loads. This article explores the different kinds of V-belts available, their specifications, advantages, and applications.

Understanding Transmission Rubber V-Belts Key Aspects and Benefits

1. Regular Inspections As mentioned, inspect the belt regularly for signs of wear and damage.

Function of the Alternator Belt

- Replacement Schedule Adhering to the manufacturer’s recommendations for replacement can prevent unexpected issues. Typically, V-belts should be replaced every 40,000 to 60,000 kilometers, but factors such as driving conditions can affect this lifespan.

3. डिप्रिसियसन नयाँ भ्यानको मूल्य प्रयोगमा ल्याउँदा झन् छिटो घट्ने गर्दछ। यद्यपि प्रयोग गरिएको भ्यानमा यो समस्या कम हुन्छ। एक पटकमा गाडी किनिसकेपछि, यसले पहिले नै केही मूल्य घटाइसकेको हुन्छ, जुन पुनः बिक्री गर्दा फाइदाजनक हुन्छ।

When it comes to the intricate machinery of modern vehicles, understanding the components that contribute to their functionality is vital. Among these, the timing belt plays a critical role, serving as a connective thread that synchronizes the engine's operations. Its importance cannot be overstated, as it ensures that the engine's valves open and close at the correct intervals, thereby facilitating efficient combustion and engine performance.

5. Dash Cam

2. Gear Changing Some systems utilize multiple gears to achieve different speed settings. By shifting between gears, the output speed can be modified without altering the motor's performance.

Applications Across Industries

V-belts are made from various materials, each contributing specific properties

Craftsmanship and Quality

1. Regular Inspection Check the belts and pulleys for signs of wear, such as cracks, fraying, or glazing. Early detection of issues can prevent more significant problems down the line.

V-belt systems represent an essential innovation in motorcycle design, providing countless benefits that influence performance and rider satisfaction. Their smooth operation, ease of maintenance, and lightweight design cater to both the casual rider and the serious enthusiast. As technology continues to advance, we can expect further improvements in V-belt systems, leading to enhanced performance and efficiency in motorcycles.

V-belts are generally made from durable materials such as rubber, fabric, and synthetic compounds. However, they can wear over time due to environmental factors, engine heat, and constant movement. Regular inspection of V-belts is essential to detect signs of wear, such as cracking, fraying, or glazing.

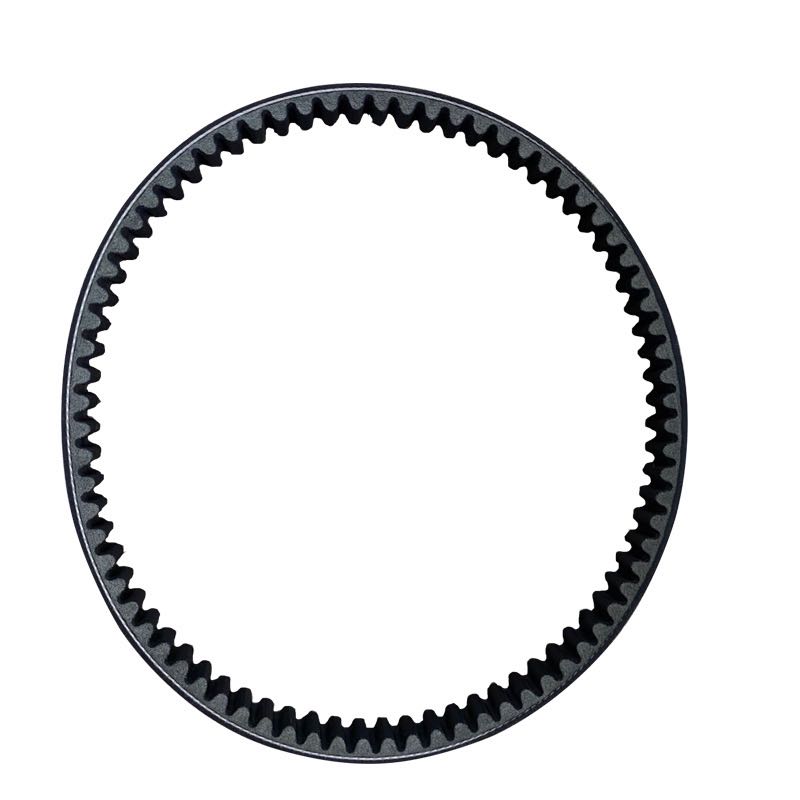

Small toothed drive belts, also known as timing belts or synchronous belts, play a crucial role in the functioning of various machines and devices. These belts are characterized by their toothed design, which allows for a precise and reliable connection between rotating components. In this article, we will explore the features, benefits, and applications of small toothed drive belts to understand their significance in modern engineering.

En av fordelene med å bruke belter er at de kan overføre kraft over betydelige avstander. Dette gjør at de kan koble sammen flere komponenter i et produksjonssystem. I tillegg kan belter brukes til å håndtere forskjellige hastigheter og dreiningsmomenter, avhengig av design og materialvalg.

The Role of Timing Belt Replacement

timing belt use

When it comes to power transmission in various mechanical applications, one of the most critical components that plays a pivotal role is the V-belt. Among the various types of V-belts, the raw edge V-belt stands out due to its unique design and functionality. In this article, we will explore what raw edge V-belts are, their advantages, applications, and maintenance.

- Quality Assurance Look for suppliers who adhere to international quality standards and have a robust testing process for their products. Certifications such as ISO 9001 can be indicators of a supplier’s commitment to quality.

4. Cost Consideration While it may be tempting to go for the cheapest option, keep in mind that quality often comes at a price. Investing in a decent timing belt can save you from costly repairs down the line.

One of the crucial attributes of conveyor belt rubber is its adaptability. It can be engineered to meet specific demands, such as oil resistance for applications in petrochemical industries or heat resistance for high-temperature environments. Additionally, various surface textures can be designed for enhanced grip and reduced material slippage, which is particularly important in applications involving steep inclines or declines.

What is a Belt Drive?

In the realm of industrial machinery and automotive applications, the importance of drive belts cannot be overstated. These components play a crucial role in transferring power from one part of a machine to another, ensuring seamless operation and efficiency. Among the various types of drive belts available, custom drive belts have gained significant popularity due to their adaptability and performance. In this article, we will explore what custom drive belts are, their applications, benefits, and the factors to consider when opting for a custom-made solution.

Key Factors to Consider

Characteristics of 8PK V-Belts