Current location:

Links:

-

Moreover, with advancements in material science, these bearings are now available in various materials and coatings, enhancing their performance in harsh environments. From stainless steel for corrosion resistance to ceramic for higher temperature tolerance, the 62207 bearing can be tailored to suit a wide range of operational conditions. The 638 ZZ bearing has the following specifications The rolling elements within these bearings are typically spherical or cylindrical rollers, which offer superior load capacity compared to ball bearings. The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear

The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear

The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear The larger contact patch between the rollers and races further enhances the bearing's ability to handle heavy loads while minimizing friction and wear taper rolling bearing supports. This makes taper rolling bearing supports particularly well-suited for applications where high static or dynamic loads are common, such as in gearboxes, pumps, and conveyance systems. In terms of innovation, manufacturers continue to refine the 6308 z bearing by exploring new materials and coatings that can boost its resistance to wear and tear. Moreover, ongoing research focuses on improving lubrication techniques to further reduce energy consumption and increase operational efficiency. In conclusion, miniature deep groove ball bearings are an essential component in various applications due to their compact size, high load capacity, and low friction characteristics. Proper maintenance and care are essential for their longevity and performance. By understanding their construction, working principles, applications, and maintenance, you can make the most of these miniature deep groove ball bearings in your applications. The versatility of the 25877 bearing makes it suitable for a wide range of applications across various industries. Some potential applications include In addition to load capacity and speed rating, the bearing's size also affects its compatibility with other components in the machine

taper rolling bearing supports. This makes taper rolling bearing supports particularly well-suited for applications where high static or dynamic loads are common, such as in gearboxes, pumps, and conveyance systems. In terms of innovation, manufacturers continue to refine the 6308 z bearing by exploring new materials and coatings that can boost its resistance to wear and tear. Moreover, ongoing research focuses on improving lubrication techniques to further reduce energy consumption and increase operational efficiency. In conclusion, miniature deep groove ball bearings are an essential component in various applications due to their compact size, high load capacity, and low friction characteristics. Proper maintenance and care are essential for their longevity and performance. By understanding their construction, working principles, applications, and maintenance, you can make the most of these miniature deep groove ball bearings in your applications. The versatility of the 25877 bearing makes it suitable for a wide range of applications across various industries. Some potential applications include In addition to load capacity and speed rating, the bearing's size also affects its compatibility with other components in the machine Ball bearings are a crucial component in many machines and devices, providing smooth and efficient rotation for various applications. One commonly used type of ball bearing is the 6002zz bearing, known for its versatility and durability. * Small motors and generators Mounted Spherical Roller Bearings Engineered for Robust Performance The 6310 RS bearing is a highly reliable and efficient bearing designed for use in various industrial applications. This article provides a comprehensive guide to help you understand the features, benefits, and proper usage of this bearing. * Monitor the temperature and vibration levels of the bearing during operation to detect any potential issues early on. Taper roller bearings are also known for their high load capacity and durability. The combination of the tapered roller design and the cage structure provides a strong and stable support system that can withstand heavy loads over a long period of time. This makes them a popular choice for applications such as heavy machinery, construction equipment, and industrial machinery. * Robotics and automation Integrated into robotic arms, conveyor systems, and other automated machinery. Overall, the 32028 bearing is an essential component in many different types of machinery and equipment. Its ability to support heavy loads, reduce friction, and operate in challenging conditions make it a valuable asset for industries around the world. Whether used in automotive, aerospace, or manufacturing applications, this type of bearing continues to play a crucial role in keeping the wheels of industry turning. The 'ZZ' suffix is a code for the bearing's shield configuration. It signifies that the bearing has metal shields on both sides, providing protection against dust and small particles, extending the bearing's life. These shields also help to maintain lubricant within the bearing, reducing the need for frequent relubrication. Economy and Local Businesses 6014 Bearing Dimensions A Comprehensive Guide The 6311 bearing is a single-row deep groove ball bearing, which means it consists of an outer ring, inner ring, and a cage that holds a set of balls. The outer ring has two raceways, while the inner ring has one raceway. The balls roll between these raceways, providing support and reducing friction between the rings. Maintenance The Promise and Challenge of 600 Mbps High-Speed Internet In addition to material advancements, the 6007 2rs bearing has also benefited from improvements in manufacturing processes

8. Static load rating 6.6 kN The 592A bearing is designed with precision to withstand heavy loads and provide reliable support. It consists of an inner ring, outer ring, rolling elements, and cage that work together to reduce friction and prevent wear. The inner ring is designed to fit tightly around the shaft, while the outer ring provides a stable base for the rolling elements. The rolling elements, typically made of steel or ceramic, roll smoothly between the inner and outer rings, reducing friction and wear. The cage keeps the rolling elements evenly spaced, preventing them from colliding and ensuring uniform rotation. In general, larger bearings have higher load capacity due to their increased surface area and ability to withstand greater forces. Deep groove bearings are typically made from high-quality steel or chrome steel, which provides excellent strength and durability. Proper lubrication is also critical to ensuring optimal performance and longevity of deep groove bearings.

- Spherical Roller Bearings: Spherical roller bearings are commonly used in applications where misalignment compensation, high load capacity, and the ability to handle dynamic or oscillating loads are required, such as in heavy industrial machinery, mining equipment, and vibratory screens.

Another important feature of the 6312 bearing size is its durability and reliability On the other hand, spherical roller bearings have an inner ring, an outer ring, and a cage with barrel-shaped rollers. These bearings are designed to accommodate both radial and axial loads, making them highly versatile. Spherical roller bearings are particularly useful in applications where the shaft has a significant misalignment or where there is a need for high thrust loads. The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation

On the other hand, spherical roller bearings have an inner ring, an outer ring, and a cage with barrel-shaped rollers. These bearings are designed to accommodate both radial and axial loads, making them highly versatile. Spherical roller bearings are particularly useful in applications where the shaft has a significant misalignment or where there is a need for high thrust loads. The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation

The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation The barrel-shaped rollers in spherical roller bearings allow them to accommodate misalignment and still maintain proper contact between the bearing surfaces, ensuring smooth operation cylindrical roller bearings or spherical roller bearing. Width (W) Natural Beauty One of the primary advantages of duplex angular contact ball bearings is their ability to withstand high radial and axial loads. The dual arrangement allows for load distribution across both units, increasing their durability and service life The dual arrangement allows for load distribution across both units, increasing their durability and service lifeduplex angular contact ball bearing. Moreover, their capacity to manage combined loads makes them ideal for applications where both radial and thrust loads are present, such as in gearboxes, spindles, and pumps

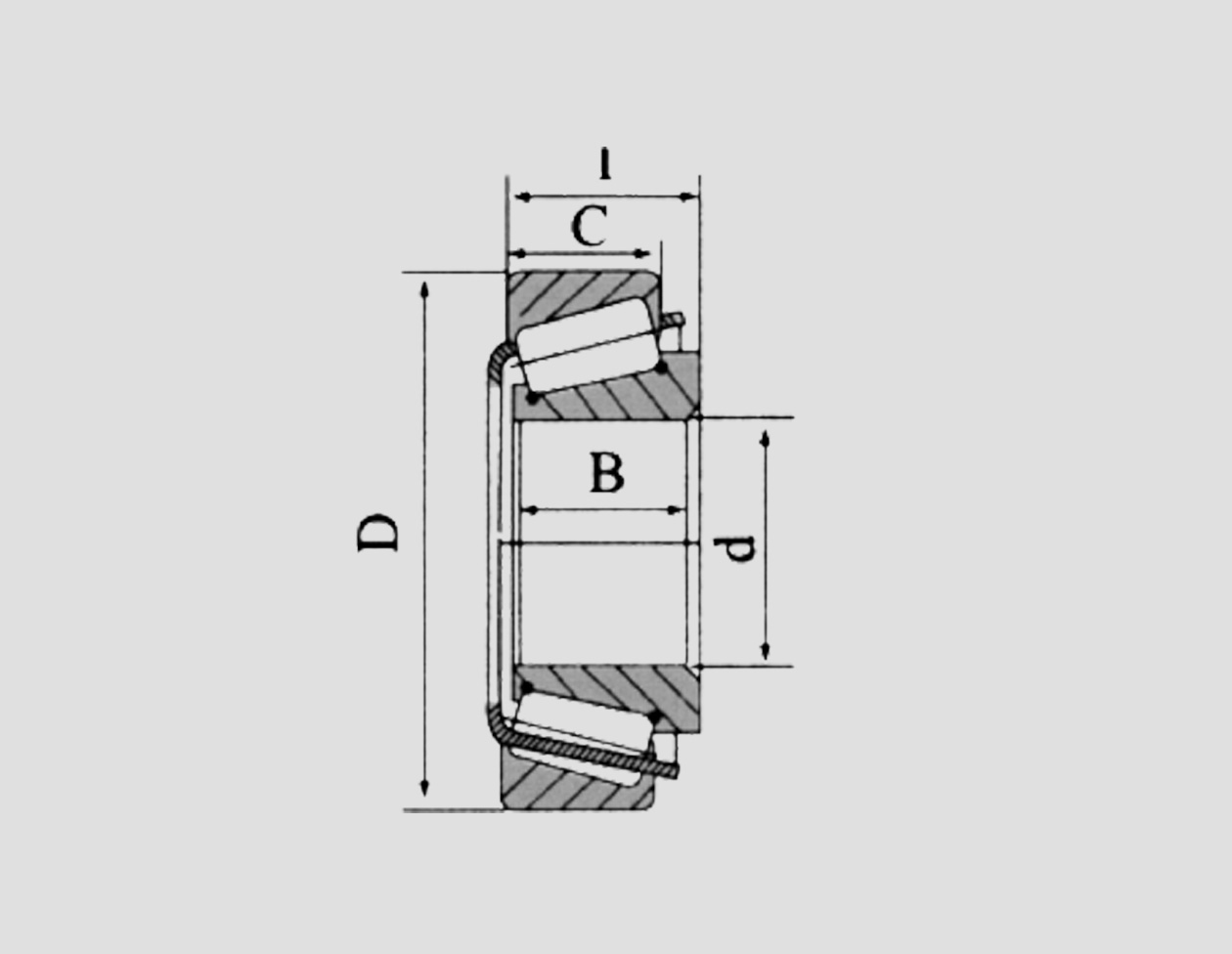

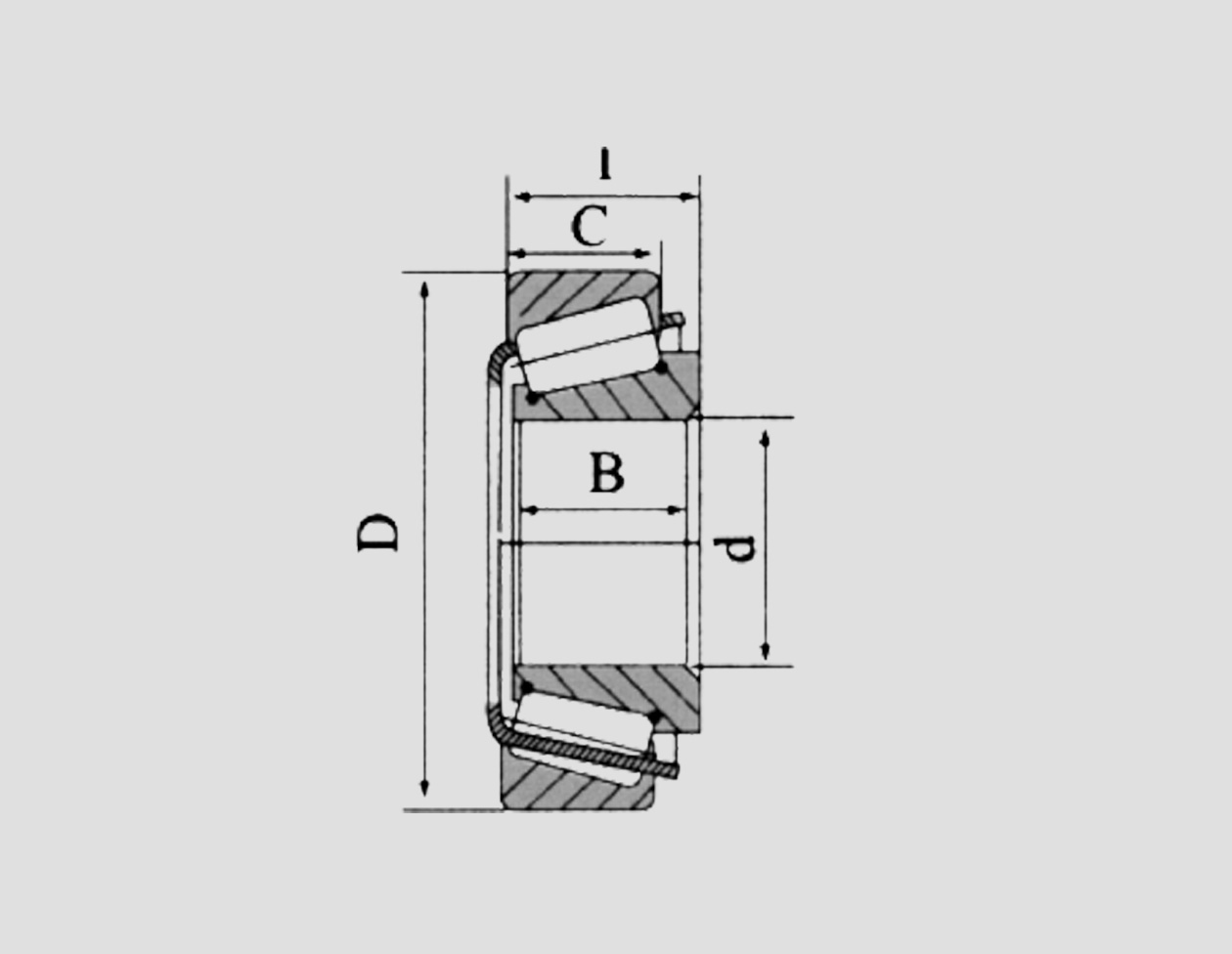

cylindrical roller bearings or spherical roller bearing. Width (W) Natural Beauty One of the primary advantages of duplex angular contact ball bearings is their ability to withstand high radial and axial loads. The dual arrangement allows for load distribution across both units, increasing their durability and service life The dual arrangement allows for load distribution across both units, increasing their durability and service lifeduplex angular contact ball bearing. Moreover, their capacity to manage combined loads makes them ideal for applications where both radial and thrust loads are present, such as in gearboxes, spindles, and pumps . Radial Clearance of Spherical Roller Bearings A Comprehensive Guide There are several reasons that may have contributed to the increase in the price of bearing 6312. One major factor is the overall increase in raw material costs. The materials used in the manufacturing of bearings, such as steel and lubricants, have experienced a surge in prices in recent times. This has resulted in higher production costs for bearing manufacturers, which in turn has led to an increase in the final price of the bearings. 4. Basic dynamic load rating (C) The maximum load that the bearing can sustain under dynamic conditions, without damage, expressed in Newtons (N) or pounds (lb). One of the key benefits of using a 51312 thrust bearing is its ability to handle both high axial loads and shock loads. This makes it an ideal choice for applications where sudden changes in load or direction are common, such as in heavy-duty machinery, automotive transmissions, and hydraulic systems. By providing a stable and reliable support system, the 51312 thrust bearing helps to prevent damage to the surrounding components and ensures the smooth operation of the equipment. The ball bearing 6203 has a standard bore diameter of 17 millimeters, an outer diameter of 40 millimeters, and a width of 12 millimeters. These dimensions are critical for ensuring a proper fit and function within a machine or device. Additionally, the bearing's dynamic load rating is 9.55 kilonewtons, while the static load rating is 4.8 kilonewtons. These ratings indicate the maximum loads that the bearing can withstand under different conditions, making them important considerations for selecting the appropriate bearing for a particular application. Types of Bearing 32211 Despite their straightforward design, single roller bearings are not immune to wear and tear. Proper lubrication is key to prolonging their lifespan and ensuring that they operate at peak efficiency. Regular maintenance checks help identify potential issues before they escalate into costly repairs. The Significance of the 6218 ZZ Bearing in Modern Industry Bearings are essential components in various mechanical systems, providing support, reducing friction, and enabling smooth rotation. The 6302 bearing is a popular choice due to its reliability, durability, and cost-effectiveness. This article delves into the key features, specifications, and applications of the 6302 bearing, highlighting its importance in various industries. The 6209 2RS bearing is a key component in many industrial applications, playing a crucial role in ensuring smooth and efficient operation of machinery and equipment. This type of bearing is designed to withstand high levels of radial and axial loads, making it ideal for use in heavy-duty machinery such as conveyor systems, agricultural equipment, and automotive applications. The SKF taper roller bearing size chart in mm includes a wide range of sizes to cater to different applications. Whether it is a small electric motor or a massive industrial machine, SKF has a bearing to suit every need

. Radial Clearance of Spherical Roller Bearings A Comprehensive Guide There are several reasons that may have contributed to the increase in the price of bearing 6312. One major factor is the overall increase in raw material costs. The materials used in the manufacturing of bearings, such as steel and lubricants, have experienced a surge in prices in recent times. This has resulted in higher production costs for bearing manufacturers, which in turn has led to an increase in the final price of the bearings. 4. Basic dynamic load rating (C) The maximum load that the bearing can sustain under dynamic conditions, without damage, expressed in Newtons (N) or pounds (lb). One of the key benefits of using a 51312 thrust bearing is its ability to handle both high axial loads and shock loads. This makes it an ideal choice for applications where sudden changes in load or direction are common, such as in heavy-duty machinery, automotive transmissions, and hydraulic systems. By providing a stable and reliable support system, the 51312 thrust bearing helps to prevent damage to the surrounding components and ensures the smooth operation of the equipment. The ball bearing 6203 has a standard bore diameter of 17 millimeters, an outer diameter of 40 millimeters, and a width of 12 millimeters. These dimensions are critical for ensuring a proper fit and function within a machine or device. Additionally, the bearing's dynamic load rating is 9.55 kilonewtons, while the static load rating is 4.8 kilonewtons. These ratings indicate the maximum loads that the bearing can withstand under different conditions, making them important considerations for selecting the appropriate bearing for a particular application. Types of Bearing 32211 Despite their straightforward design, single roller bearings are not immune to wear and tear. Proper lubrication is key to prolonging their lifespan and ensuring that they operate at peak efficiency. Regular maintenance checks help identify potential issues before they escalate into costly repairs. The Significance of the 6218 ZZ Bearing in Modern Industry Bearings are essential components in various mechanical systems, providing support, reducing friction, and enabling smooth rotation. The 6302 bearing is a popular choice due to its reliability, durability, and cost-effectiveness. This article delves into the key features, specifications, and applications of the 6302 bearing, highlighting its importance in various industries. The 6209 2RS bearing is a key component in many industrial applications, playing a crucial role in ensuring smooth and efficient operation of machinery and equipment. This type of bearing is designed to withstand high levels of radial and axial loads, making it ideal for use in heavy-duty machinery such as conveyor systems, agricultural equipment, and automotive applications. The SKF taper roller bearing size chart in mm includes a wide range of sizes to cater to different applications. Whether it is a small electric motor or a massive industrial machine, SKF has a bearing to suit every need

skf taper roller bearing size chart mm. The company's extensive experience and expertise in bearing design ensure that each product meets the highest quality standards. One of the key advantages of bearing NU 316 is its ability to withstand high temperatures. The bearings are made from high-quality steel, which provides excellent heat resistance and ensures long-lasting performance even in harsh operating conditions. This is particularly important in industries where machinery operates continuously for extended periods, such as mining and cement production. The design of these bearings includes a deep groove, which allows for increased ball capacity. This enhances the load-carrying capability and provides better contact stress distribution within the bearing. The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial high temperature deep groove ball bearing. Miniature Deep Groove Ball Bearings A Comprehensive Guide One of the key advantages of the 6211 2rs bearing is its ability to minimize friction and reduce heat generation during operation. This helps to extend the lifespan of the bearing and the equipment it is installed in. The two rubber seals on the bearing also act as a barrier against moisture and dirt, preventing premature wear and damage

high temperature deep groove ball bearing. Miniature Deep Groove Ball Bearings A Comprehensive Guide One of the key advantages of the 6211 2rs bearing is its ability to minimize friction and reduce heat generation during operation. This helps to extend the lifespan of the bearing and the equipment it is installed in. The two rubber seals on the bearing also act as a barrier against moisture and dirt, preventing premature wear and damage

6211 2rs bearing. Step 1 Preparation