Links:

Factors Influencing Grating Thickness

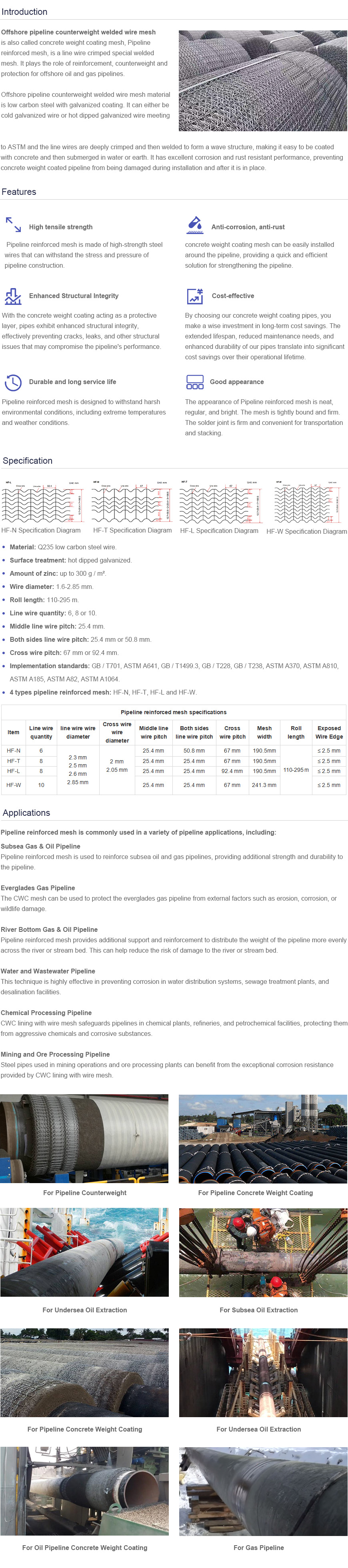

steel grating thickness

5. Taşınma ve Montaj Maliyetleri Galvanizli ızgaraların taşınması ve montajı da maliyetleri artırabilir. Özellikle ağır ve büyük ızgaraların montajı, uzman iş gücü ve özel ekipman gerektirebilir. Montaj sürecinin planlanması, toplam maliyeti etkileyen kritik bir aşamadır.

The applications of shale screens in Water Treatment

.توری های فولادی یکی از مصالح پرکاربرد در صنعت ساخت و ساز و مهندسی عمران به شمار میروند. این مصالح به خاطر مقاومت بالا و قابلیت تحمل بار زیاد، در بسیاری از پروژهها مورد استفاده قرار میگیرند. یکی از سوالات متداول در مورد توری های فولادی، اندازهها و ابعاد مختلف آنهاست. این مقاله به بررسی اندازههای مختلف توری فولادی و نکات مرتبط با انتخاب اندازه مناسب میپردازد.

트렌치 드레인 그레이트는 현대 건축과 조경 디자인에서 필수적인 요소로 자리잡고 있습니다. 이 배수 시스템은 표면에서 맺힌 물을 효과적으로 배출함으로써, 침수와 수분 문제를 예방하는 역할을 합니다. 특히, 비가 많이 오는 지역이나 물이 많이 고이는 지역에서는 그 필요성이 더욱 두드러집니다.

2. Bar Thickness and Spacing The thickness of the bars and the spacing between them also play crucial roles in the pricing structure. Thicker bars that can support heavier loads will generally cost more. Additionally, tighter spacing can increase the material usage, further impacting the price.

What is a Trench Drain?

Overall, galvanized steel bar grating’s durability, resistance to corrosion, cost-effectiveness, flexibility in design, and easy maintenance make it an excellent choice for a wide range of applications, from industrial settings to outdoor infrastructure. Whether used for flooring, walkways, or drainage covers, galvanized steel bar grating offers a reliable and long-lasting solution.

.Furthermore, regular maintenance, such as inspections for corrosion or wear, is vital, particularly in environments exposed to chemicals or extreme weather conditions.

The price of floor grating largely depends on the material used. Common materials include steel, aluminum, fiberglass, and plastic. Steel grating is typically the most economical option, often used in industrial applications due to its strength and resistance to heavy loads. Aluminum grating, while slightly more expensive, is lightweight and resistant to corrosion, making it suitable for outdoor and marine environments. Fiberglass grating is ideal for corrosive environments where durability is essential. Although it generally comes at a higher price, its longevity can offset initial costs.

.

These gratings can be used in many different ways. It can keep many selected structures clean and tidy. However, it has a weaker tensile strength compared to its counterparts.

La pavimentazione a reticolo aperto in acciaio inox rappresenta una soluzione innovativa e versatile per una vasta gamma di applicazioni. Questo materiale combina robustezza e leggerezza, offrendo una superficie sicura e durevole per ambienti industriali, commerciali e residenziali.

Metallrippen für Treppenstufen Tragfähigkeit, Sicherheit und Design

In conclusion, industrial floor grates are indispensable elements in modern industrial environments. They provide critical drainage capabilities, enhance safety, and contribute to the overall efficiency of operations. Understanding the features, materials, and installation guidelines of these components can help industries choose the right solutions for their specific needs, ultimately leading to a safer and more productive workplace.

En av de mest populre typene grating er perforert grating, som ofte brukes i industrielle settinger. Denne typen grating gir god ventilasjon og lysgjennomgang, noe som er avgjrende for mange arbeidsmiljer. P den andre siden har vi gitterrister, som ofte brukes i konstruksjon og tilbyr hy styrke og stabilitet. Gitterrister er ogs lett installere, noe som gjr dem til et populrt valg blant entreprenrer.

grating for sale

Thanh gạch mang lại nhiều ưu điểm như khả năng chịu lực cao, độ bền lâu dài và khả năng chịu thời tiết tốt. Nhờ vào thiết kế của nó, thanh gạch còn có khả năng thoát nước tốt, nên được ưa chuộng trong các khu vực ẩm ướt.

Ein A325%-Gitter ist ein optisches Gitter, das speziell entworfen wurde, um Licht in verschiedene Wellenlängen zu zerlegen. Die Bezeichnung „A325%“ verweist auf bestimmte Parameter des Gitters, wie die Gitterkonstante, die Materialbeschaffenheit und die Verarbeitungsmethoden, die seine Eigenschaften bestimmen. Diese Gitter sind üblicherweise aus Materialien gefertigt, die eine hohe optische Klarheit und Stabilität bieten, wie z. B. Quarz oder spezielle Polymere.

Galvanizli ızgaralar, inşaat ve endüstride yaygın olarak kullanılan önemli yapısal elemanlardır. Bu ızgaralar, dayanıklılığı ve korozyon direnci ile bilinir ve genellikle çelikten imal edilir. Galvanizleme işlemi, çelik yüzeyinin çinko ile kaplanmasını içerir; bu da onu paslanmaya karşı korur. Ancak, galvanizli ızgaraların maliyeti, birçok faktöre bağlıdır ve proje maliyetlerini etkileyen önemli bir unsurdur.

हेलीडेक नेट एयरलिफ्टको नयाँ आयाम

A greta de rivetado, também conhecida como greta de rebites, é um componente estrutural e estético que tem ganhado destaque em diversas áreas, desde a arquitetura até o design de interiores. Estas grelhas, formadas por uma série de tiras metálicas ou de madeira unidas por rebites, não apenas proporcionam suporte e estabilidade, mas também adicionam uma dimensão visual única a qualquer espaço.

Steel Grating

Inoltre, il pavimento in grigliato d'acciaio è facile da pulire e mantenere. La sua superficie liscia e aperta permette un rapido drenaggio dei liquidi, riducendo il rischio di slip e cadute. Questo lo rende ideale per applicazioni in cui la sicurezza è una priorità, come ristoranti, laboratori e aree di produzione alimentare. Grazie alla sua resistenza alla corrosione, è anche una scelta eccellente per ambienti esterni o situazioni in cui è esposto a sostanze chimiche.

steel grate flooring

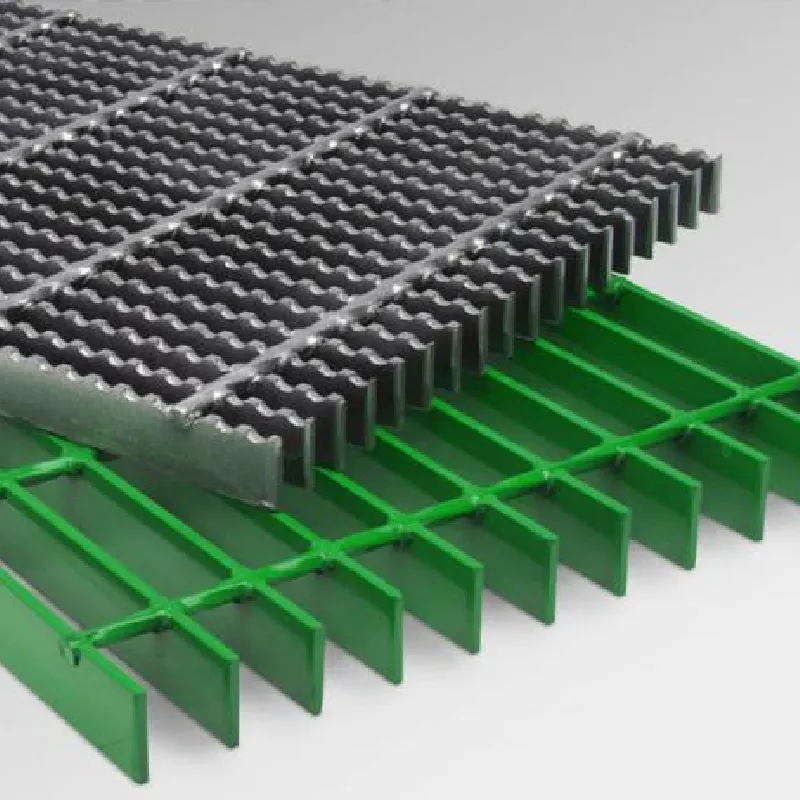

Aluminum bar grating offers a variety of options to suit different application needs. The flush top design provides a smooth surface for walking, while the rectangular bar and I-bar options offer enhanced strength and stability. Plank grating features a durable and slip-resistant surface, making it ideal for industrial settings.

1. วัสดุ กรองระบายน้ำทิ้งมักทำจากวัสดุที่หลากหลาย เช่น เหล็กกล้า สแตนเลส หรือพลาสติก แต่ละวัสดุมีข้อดีและข้อเสียที่แตกต่างกัน เช่น เหล็กกล้าอาจมีความทนทานสูง แต่สามารถเป็นสนิมได้หากไม่ได้รับการดูแล ในขณะที่พลาสติกมีน้ำหนักเบาและไม่เป็นสนิม แต่ความแข็งแรงอาจไม่เท่ากับเหล็ก

replacement trench drain grates

Безопасность также является важным аспектом, на который стоит обратить внимание при использовании мягкой стали в решетчатых настилах. Структура из сетки обеспечивает хорошее сцепление, что снижает вероятность скольжения. Это особенно актуально в промышленных условиях или на строительных площадках, где безопасность работников имеет первостепенное значение. В дополнение к этому, решетчатые настилы могут быть адаптированы для выполнения специфических требований, таких как антискользящие поверхности, которые делают их ещё более безопасными для использования.

Kuphatikiza apo, serrated steel flat bar imakhala ndi kayendetsedwe kabwino omwe angathandize pochita ntchito. Kapangidwe kake ka serrated kumapangitsa kuti zipangizozi zikhale zoyenda mwachangu komanso kwambiri. Izi zimathandiza poyika zinthu mwachangu komanso mwachitukuko, zomwe zimachititsa kuti zithe kulumikizana.

- Industriële Omgevingen In fabrieken en magazijnen waar vloeistoffen regelmatig worden afgevoerd, bieden roestvrijstalen graten een robuuste en betrouwbare oplossing.

Stålgrating för Trappsteg En Hållbar och Säker Lösning

Kolejnym istotnym aspektem zastosowania węglanowych ekranów jest ich pozytywny wpływ na ochronę środowiska. Dzięki skutecznej filtracji i minimalizacji odpadów, przemysł naftowy i gazowy staje się coraz bardziej przyjazny dla środowiska. W dobie zmian klimatycznych i rosnącej presji na ograniczenie emisji, innowacyjne rozwiązania, takie jak ekrany węglanowe, zyskują na znaczeniu.

이 시스템의 가장 큰 장점은 설치의 유연성입니다. 다양한 길이와 깊이로 제작 가능하여, 특정 공간의 필요에 맞게 조정할 수 있습니다. 또한, 이 드레인 시스템은 시각적으로도 세련되어, 공간의 미관을 해치지 않으면서 기능성을 제공합니다.

6 trench drain grate

Shale shaker screen mesh, a specialized type of filtering medium, is designed to separate solid particles from drilling fluids in oil and gas exploration. Constructed from durable materials such as stainless steel or synthetic fibers, these meshes are engineered to withstand the harsh conditions of drilling environments while maintaining their structural integrity and filtering efficiency.