Links:

- Cancer The company's achievements are further highlighted by their global reach. With a distribution network spanning multiple continents, Sachtleben ensures that their premium TiO2 is accessible to customers worldwide. This international presence not only reflects their commercial success but also their reputation for reliable delivery and excellent customer service. In the electronics sector, Zinc Barium Sulphate is employed in the production of electronic components, benefiting from its excellent electrical insulation properties. It is also used as a dielectric material in capacitors and other electronic devices. Moreover, in agriculture, it is used as a source of essential minerals, zinc and barium, for plant nutrition.

- Taxation and Depreciation

- Some sunscreens will say “non-nano” on the label. Choose those, and if the label doesn’t specify if titanium dioxide is nanoparticle size, call or email the company and ask the particle size of the active sunscreen ingredient. Another reason to choose [Supplier Name] as your titanium white oem supplier is our commitment to customer service Rutile TiO2, a naturally occurring mineral, is renowned for its exceptional properties. It is highly reflective, which means that when incorporated into wallpaper, it can significantly brighten any room. This makes it an ideal choice for those seeking to create a light and airy atmosphere in their living spaces.

- Color added

According to the American Chemistry Council, titanium dioxide (TiO2) is an inorganic substance that's used as a white powder in a variety of industrial and consumer goods, including in sunscreen, cosmetics, toothpaste, paint, plastics, food and more.

Despite a bullish trends ruling the market for the bulk of the period, the North American market had mixed sentiments in the fourth quarter of 2021. This was mostly due to the adequate pushback from the supply-demand imbalance, which was further compounded by rising natural gas prices, which had taken a proper toll on the future production of numerous minerals, including titanium dioxide. An increase in COVID instances had prompted concerns in ore feedstock. As a result, during the fourth quarter of 2021, the FD UGSC (USA) quarterly average negotiations for the chemical CP Rutile Grade were finalised at USD 4434 per tonne.

In the dyeing industry, titanium dioxide is valued for its excellent light-scattering properties, which contribute to the vibrant and long-lasting colors of dyed materials. By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight

By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight plastic and dyeing used titanium dioxide r218 factory. R218 factory produces titanium dioxide that is specifically designed for use in dyes, allowing textile manufacturers to create high-quality, colorfast materials for a variety of applications.

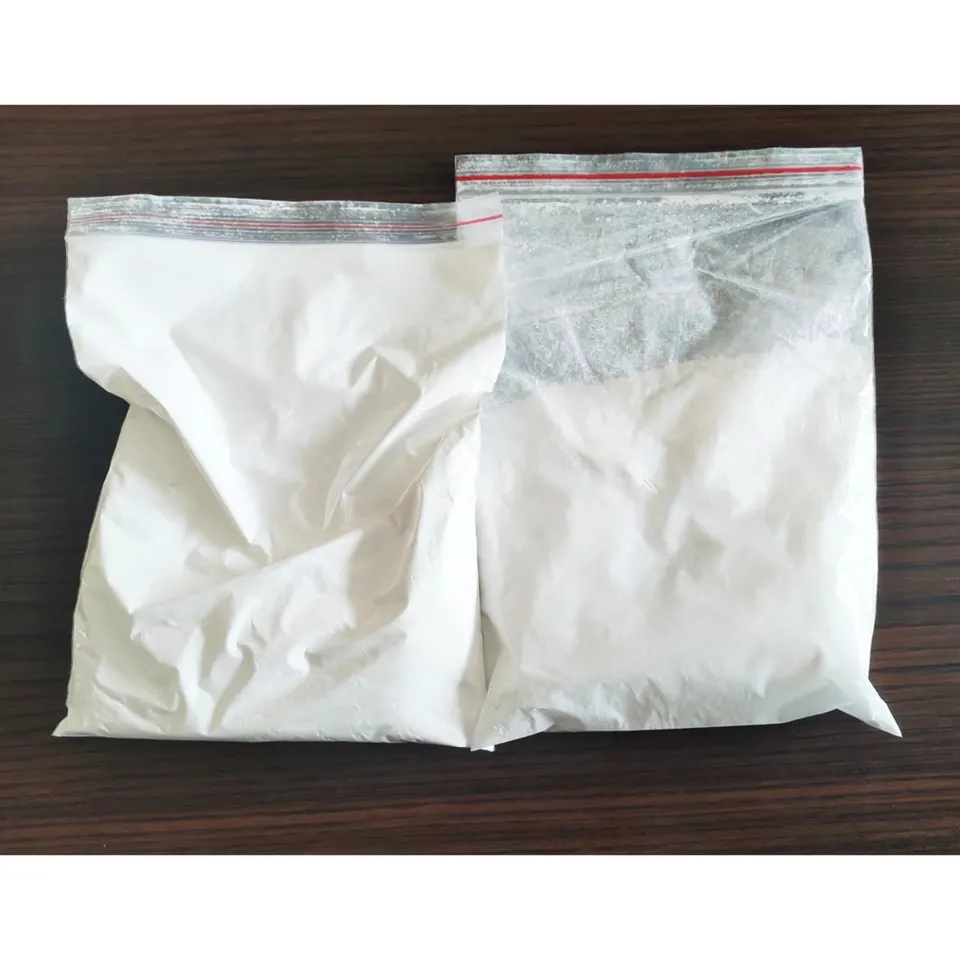

plastic and dyeing used titanium dioxide r218 factory. R218 factory produces titanium dioxide that is specifically designed for use in dyes, allowing textile manufacturers to create high-quality, colorfast materials for a variety of applications. Does not work with hydrogen sulfide and alkaline solutions. It is easy to decompose in the presence of acid to produce hydrogen sulfide gas. It is easily oxidized in the air and deteriorates after moisture. Whiteness and hiding power are strong.

Titanium Dioxide R605, often abbreviated as TiO2 R605, is a high-quality, premium-grade pigment that boasts an array of benefits. As a powder coating, it offers superior durability, resistance to UV degradation, and excellent color retention. Its chemical stability and heat resistance make it ideal for use in harsh environments, ensuring longevity and maintaining aesthetic appeal even under extreme conditions. In conclusion, the manufacturers of zinc barium sulfate play a pivotal role in supplying industries with a vital component that ensures products are visually appealing and perform as expected. Their commitment to quality, environmental stewardship, and continuous improvement positions them well to meet the evolving needs of their global customer base. As technology advances and consumer preferences shift, these manufacturers are poised to adapt and thrive, continuing to supply high-quality zinc barium sulfate for years to come. The robustness of calcium compounds is not only limited to their diverse applications but also reflects in their stability during storage and transportation. This durability makes them an ideal product for wholesale manufacturers who often deal with long supply chains and need products that can maintain quality throughout the distribution process.The produced barium sulfide enters the leacher, and the temperature is controlled above 65°C to obtain a barium sulfide content of 70%, and then enters the clarification barrel, add zinc sulfate for reaction after clarification, control the zinc sulfate content to be greater than 28%, pH=8~9, and obtain a mixture of barium sulfate and zinc sulfide with a density of 1.296~1.357 g/cm3.

Among the raw materials for coating production, titanium dioxide is more ideal, followed by lithopone. The covering power of lithopone is only that of titanium dioxide, and the price of lithopone is much lower than that of titanium dioxide, so lithopone still occupies a large market share.

Market Trends The production process in a nano-TiO2 factory begins with the selection of high-purity titanium precursors. Through precise control over reaction conditions, including temperature, pressure, and pH levels, scientists can manipulate the formation of either anatase or rutile phases. Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms

Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms Advanced techniques such as hydrothermal synthesis, sol-gel processes, and chemical vapor deposition are employed to achieve the desired nanoscale dimensions and crystalline forms anatase and rutile nano-tio2 factory.

anatase and rutile nano-tio2 factory. zinc oxide content, %

Hiding power

Titanium dioxide is widely used in coatings due to its excellent UV resistance, opacity, and durability. It is commonly used in paints, coatings, and pigments to improve their performance and appearance. Titanium dioxide can effectively scatter and reflect UV rays, making it an ideal choice for outdoor applications that require protection against sunlight. Its high opacity also helps coatings achieve better coverage and color consistency. In addition to its production capabilities, the China Titanium Dioxide Plant is also dedicated to sustainability and environmental protection

china titanium dioxide plant. The plant has implemented eco-friendly practices to minimize its impact on the environment, such as using renewable energy sources and reducing waste production. This commitment to sustainability has not only benefited the local community but has also enhanced the plant's reputation as a responsible corporate citizen.

Another common use of titanium IV oxide is in food coloring. Titanium dioxide is a FDA-approved food additive that is used to enhance the color of various food products. It is commonly used in candies, pastries, and dairy products to create vibrant colors. Titanium dioxide is a safe food additive that is used in small quantities to enhance the visual appeal of food products.

For the First Quarter of 2022

Titanium dioxide, commonly known as TiO2, is a widely used inorganic compound that exists in several crystalline forms including anatase, rutile, and brookite. Among these, anatase titanium dioxide (TiO2) with its specific surface area codenamed B101 has garnered significant attention due to its unique properties and applications in various industries. In this article, we delve into the world of titanium dioxide anatase B101 suppliers, exploring their role and the benefits they offer to consumers.Top Quality, pure Lithopone B301, Lithopone B311 powder / substance factory in China; China Lithopone B301, Lithopone B311 powder Raw Material Suppliers in China. China Lithopone B301, Lithopone B311 powder Manufacturers in China.

According to Procurement Resource, the prices of titanium dioxide are expected to showcase mixed sentiments. With trade and supply-chain normalization, the automotive and construction sectors are estimated to improve their global performance, thus affecting the prices positively.

In the world of pigments, titanium dioxide stands tall as a favorite material for its ability to provide brilliant whiteness and exceptional opacity. Its refractive index is high, making it ideal for achieving that pure, lustrous look in paints and coatings. But its capabilities don’t end there; titanium dioxide is also prized for its stability and resistance to discoloration, ensuring longevity in artistic creations and protective layers.ZnSO4 – BaS ➔ BaSO4*ZnS

Colour Characteristics

No. EFSA’s role was limited to evaluating the risks linked to titanium dioxide as a food additive. This included an assessment of relevant scientific information on TiO2, its potential toxicity, and estimates of human dietary exposure. Any legislative or regulatory decisions on the authorisations of food additives are the responsibility of the risk managers (i.e. European Commission and Member States).

References

This constant high rate of ROS production leads rapidly to extreme macromolecular oxidation, here it is observed in the AOPP and MDA detected after 3 h in samples treated with bare P25TiO2NPs (Fig. 6, Fig. 7). Macromolecular oxidation includes, among others, both protein and lipid oxidation. The ROS causes protein oxidation by direct reaction or indirect reactions with secondary by-products of oxidative stress. Protein fragmentation or cross-linkages could be produced after the oxidation of amino acid side chains and protein backbones. These and later dityrosine-containing protein products formed during excessive production of oxidants are known as advanced oxidation protein products (AOPP). They absorb at 340 nm and are used to estimate the damage to structural cell amino acids. Lipid oxidation is detected by the conjugation of oxidized polyunsaturated lipids with thiobarbituric acid, forming a molecule that absorbs light at 532 nm. Polyunsaturated lipids are oxidized as a result of a free-radical-mediated chain of reactions. The most exposed targets are usually membrane lipids. The macromolecular damage could represent a deadly danger if it is too extensive, and this might be the case. Moreover, it could be observed that cellular damage continues further and becomes irrevocable after 6 h and MDA could not be detected. This may be due to the fact that the lipids were completely degraded and cells were no longer viable. Lipids from the cell membrane are the most prone to oxidation. In fact, lipid peroxidation biomarkers are used to screen the oxidative body balance [51]. At the same time, AOPP values are up to 30 times higher for bare nanoparticles in comparison to the functionalized ones.