In terms of applications, fiber water tanks are used across a broad spectrum of industries. In agriculture, they are used for irrigation and livestock watering due to their large capacity and durability. In municipal and residential settings, they serve as reliable sources for drinking water storage, rainwater harvesting, and emergency water supply. The industrial sector benefits from these tanks for storing chemicals, fire suppression water, and processing fluids, among other uses.

As environmental concerns become increasingly prominent, many builders are seeking sustainable materials. FRP decking fits this criterion as it can be made from recycled materials, and its durability reduces the need for frequent replacements, minimizing waste over time. Furthermore, the energy required to produce and transport FRP is generally lower than that of traditional materials, contributing to a smaller carbon footprint.

Water softeners serve as a solution to the problem of hard water by replacing calcium and magnesium ions with sodium or potassium ions through a process called ion exchange. By softening the water, these systems help to eliminate scale buildup in plumbing and appliances, prolonging their lifespan and improving efficiency. Furthermore, softened water can lead to brighter and softer laundry, and enhances the lathering capabilities of soaps, making bathing and cleaning more effective.

The effectiveness of RO systems lies in their ability to remove a wide range of contaminants. Commonly treated substances include dissolved salts, organic compounds, heavy metals, and microorganisms. RO systems are known for their efficiency in removing harmful elements such as lead, arsenic, and fluoride, making them suitable for improving water quality from various sources, including municipal supplies, wells, and even seawater.

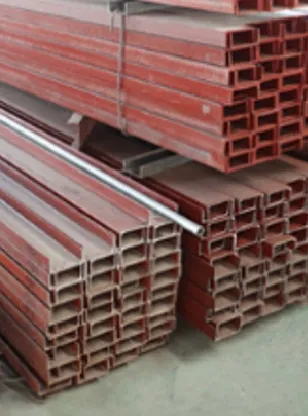

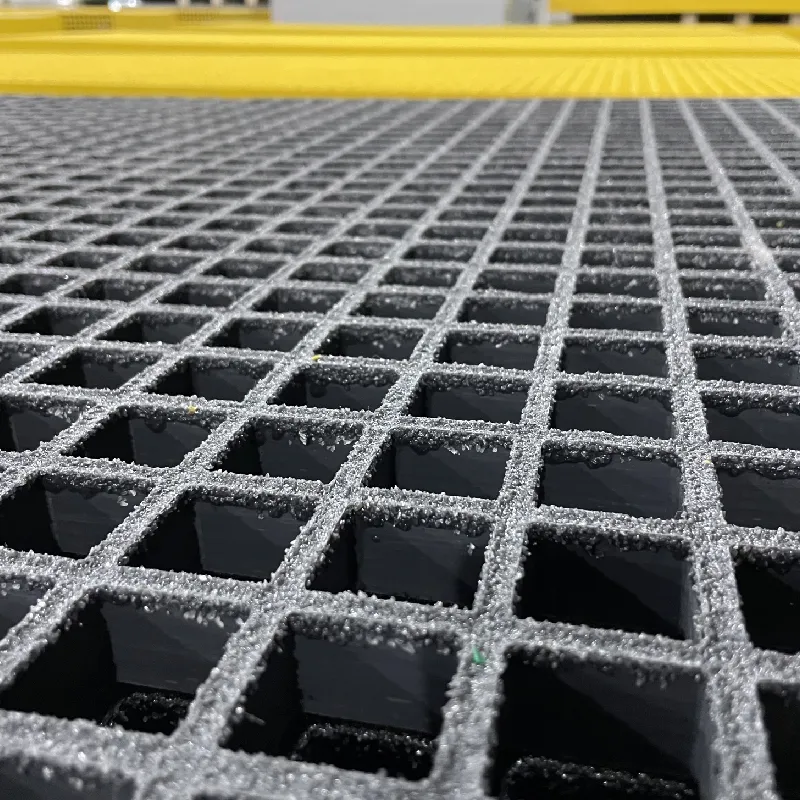

In recent years, the demand for advanced materials in construction and industrial applications has significantly increased. Among these materials, FRP (Fiber Reinforced Polymer) protruded grating has emerged as a prominent solution, offering durability, lightweight properties, and excellent resistance to environmental factors. This article will delve into the characteristics, advantages, applications, and future potential of FRP protruded grating.

One of the primary advantages of stainless steel floor grating is its exceptional durability. Unlike traditional materials such as wood or carbon steel, stainless steel is resistant to rust, corrosion, and extreme weather conditions. This quality makes it an excellent choice for outdoor environments, such as walkways, docks, and even industrial settings where exposure to moisture and harsh chemicals is common.

Fiberglass bar grating is an innovative material that has gained significant popularity across various industries due to its exceptional properties and versatility. Composed of fiberglass reinforced polymer (FRP), this type of grating offers numerous advantages over traditional materials such as steel and wood. As industries seek durable, lightweight, and corrosion-resistant solutions, fiberglass bar grating has emerged as a preferred choice for flooring, walkways, and platforms.

Fiberglass Reinforced Plastic (FRP) grating has emerged as a highly effective solution for a myriad of industrial and commercial applications, largely due to its durability, corrosion resistance, and lightweight nature. When it comes to project budgeting, one of the most critical factors to consider is the cost of FRP grating per square foot. This article will delve into the factors that influence this cost, the benefits of using FRP grating, and how to effectively calculate your overall expenses.

Furthermore, molded grating is not just a practical choice; its aesthetic appeal cannot be overlooked. Available in a variety of colors and finishes, it allows designers to incorporate functionality into their vision without compromising on style. Whether used in solar panel platforms, decorative walkways, or safety covers for industrial settings, molded grating can enhance the visual appeal of any project.

The applications of FRP vessels are widespread and diverse. In the water treatment industry, for instance, FRP tanks are commonly used for the storage and transportation of chemicals and water. Their non-corrosive nature ensures purity and safety, which is crucial for both potable water and wastewater treatment processes. Additionally, FRP vessels are increasingly utilized in the oil and gas sector for storing corrosive materials, where their durability and resistance to harsh chemicals are indispensable.

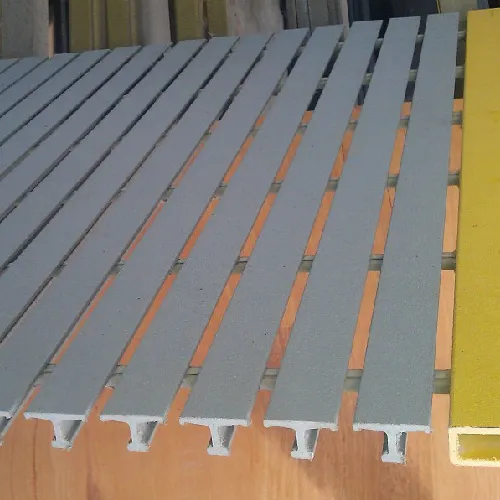

In addition to safety, grating floor plates also promote superior ventilation. The gaps between the slats allow for air circulation, which can be critical in preventing overheating in machinery and equipment. In environments where chemicals or other hazardous materials are handled, this ventilation helps to dissipate fumes and maintain a safer working atmosphere. Consequently, industries such as petrochemical plants, food processing facilities, and wastewater treatment plants frequently utilize grating floor plates to ensure compliance with safety regulations and improve overall air quality.

Anti-slip stair nosing refers to a specialized material or design applied to the edge of stairs to provide additional traction. These nosings are typically made from materials that enhance grip, helping to prevent slips caused by wet or uneven surfaces. Stair nosing can be made from various materials, including rubber, aluminum, or vinyl, each designed to offer specific benefits depending on the environment in which they are used.