Current location:

Links:

-

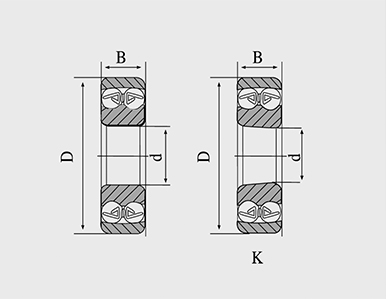

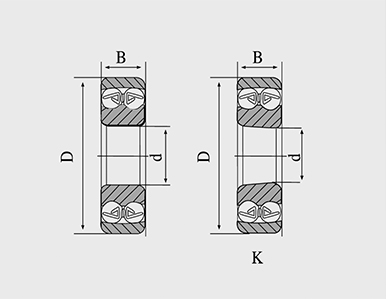

This enigmatic sequence also highlights the importance of understanding the underlying mechanisms in our increasingly digital world. As we delve deeper into the world of technology, decoding these 'languages' becomes not only a matter of curiosity but also a necessity for innovation and problem-solving. Dimensions of 6003Z Bearings One of the key features of the 33217 bearing is its ability to handle heavy loads and high speeds with ease. This makes it ideal for use in machinery that is subjected to constant wear and tear, such as in manufacturing plants or construction sites. The bearing's robust design and construction ensure that it can withstand the rigors of everyday use without compromising on performance. 5. Wide Range of Applications The versatility of the 33112 bearing allows it to be used in a wide range of industries, including automotive, aerospace, heavy machinery, and more. Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation

- High-Speed Capability: Angular contact ball bearings are designed to operate at high speeds, making them suitable for applications where rotational speed is a critical factor. These bearings are engineered to minimize friction and heat generation, allowing for efficient operation at elevated speeds. Angular contact bearings, on the other hand, are specifically designed to handle thrust loads in one direction. They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle

Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation

Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation Its ability to perform well in diverse environments makes it a valuable asset to any industrial operation 33112 bearing. When comparing durability, cylindrical roller bearings generally have a higher capacity for load carrying due to the larger contact patch between the roller and races

33112 bearing. When comparing durability, cylindrical roller bearings generally have a higher capacity for load carrying due to the larger contact patch between the roller and races cylindrical roller bearing vs ball bearing. However, they may not perform well under impact loads or high-speed applications because of their design. Ball bearings, while capable of handling combined loads, may not withstand extremely heavy radial loads as effectively as their cylindrical counterparts. Maintenance Tips for Bearing 32211 Proper installation and maintenance of the 6305 2RS bearing are essential for ensuring its longevity and performance. It is important to follow manufacturer guidelines for mounting, lubrication, and inspection to prevent premature failure and costly downtime. Regular maintenance checks will help identify any issues early on and prevent further damage to the bearing and surrounding components. In the world of mechanical engineering, the introduction of the 22313 bearing has been a game-changer, offering unprecedented levels of precision and efficiency in rotary motion applications. This specialized bearing, with its unique designation, represents a significant leap forward in the realm of bearing technology. The materials used in constructing the 22216 bearing further contribute to its excellence. Typically made from high-carbon chromium steel, the bearing offers superior hardness and resistance to corrosion. This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments

cylindrical roller bearing vs ball bearing. However, they may not perform well under impact loads or high-speed applications because of their design. Ball bearings, while capable of handling combined loads, may not withstand extremely heavy radial loads as effectively as their cylindrical counterparts. Maintenance Tips for Bearing 32211 Proper installation and maintenance of the 6305 2RS bearing are essential for ensuring its longevity and performance. It is important to follow manufacturer guidelines for mounting, lubrication, and inspection to prevent premature failure and costly downtime. Regular maintenance checks will help identify any issues early on and prevent further damage to the bearing and surrounding components. In the world of mechanical engineering, the introduction of the 22313 bearing has been a game-changer, offering unprecedented levels of precision and efficiency in rotary motion applications. This specialized bearing, with its unique designation, represents a significant leap forward in the realm of bearing technology. The materials used in constructing the 22216 bearing further contribute to its excellence. Typically made from high-carbon chromium steel, the bearing offers superior hardness and resistance to corrosion. This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments

This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments This ensures not only a longer service life but also consistent performance under extreme conditions, such as elevated temperatures or aggressive environments 22216 bearing. In conclusion, the significance of combine harvester bearings cannot be underestimated. They are the silent partners that guarantee the reliability and efficiency of this essential farming equipment. By selecting the right bearings and ensuring their proper maintenance, farmers can safeguard against mechanical failures and maximize their harvesting potential. It’s a small but powerful detail that makes a big difference in the world of agriculture. Applications The concept of bearings can be traced back to ancient times, where simple devices such as wooden blocks or stone rollers were used to support heavy objects and reduce friction. These early bearings were primarily used in applications like grinding stones and water wheels. Overall, the 32211 bearing is a versatile and efficient component that plays a crucial role in various industrial applications. Its ability to support high loads, durability, and ease of maintenance make it a preferred choice for many engineers and manufacturers. Whether it's in automotive, aerospace, construction, or manufacturing, the 32211 bearing continues to prove its value and reliability in countless applications. In addition to load-bearing, these bearings also exhibit excellent running accuracy, low noise levels, and high speed capabilities Furthermore, the installation and maintenance of bearings are influenced by their size. The 30205 bearing, due to its standardized size, can be easily replaced and serviced without requiring significant modifications to the surrounding machinery. This convenience ensures that downtime is minimized, and maintenance costs are kept low. One of the key features of the 6002RS bearing is its precision. The bearings are manufactured to exacting standards, ensuring that they have the necessary tolerances to perform at their best. This precision allows the bearings to run smoothly and efficiently, reducing wear and tear and extending their lifespan. The 51213 bearing is a critical component in various industrial applications, including automotive, aerospace, and heavy machinery. This bearing is designed to withstand high loads and provide long-lasting performance in harsh environments. In this article, we will delve into the features, benefits, and applications of the 51213 bearing, as well as provide tips for maintenance and troubleshooting. Spherical roller bearings are a type of rolling element bearing that is widely used in various industries due to its ability to accommodate misalignment and support heavy loads. One of the critical factors that determine the performance and longevity of these bearings is their radial clearance. In this article, we will delve into the concept of radial clearance, its importance, and how it is calculated and adjusted in spherical roller bearings.

22216 bearing. In conclusion, the significance of combine harvester bearings cannot be underestimated. They are the silent partners that guarantee the reliability and efficiency of this essential farming equipment. By selecting the right bearings and ensuring their proper maintenance, farmers can safeguard against mechanical failures and maximize their harvesting potential. It’s a small but powerful detail that makes a big difference in the world of agriculture. Applications The concept of bearings can be traced back to ancient times, where simple devices such as wooden blocks or stone rollers were used to support heavy objects and reduce friction. These early bearings were primarily used in applications like grinding stones and water wheels. Overall, the 32211 bearing is a versatile and efficient component that plays a crucial role in various industrial applications. Its ability to support high loads, durability, and ease of maintenance make it a preferred choice for many engineers and manufacturers. Whether it's in automotive, aerospace, construction, or manufacturing, the 32211 bearing continues to prove its value and reliability in countless applications. In addition to load-bearing, these bearings also exhibit excellent running accuracy, low noise levels, and high speed capabilities Furthermore, the installation and maintenance of bearings are influenced by their size. The 30205 bearing, due to its standardized size, can be easily replaced and serviced without requiring significant modifications to the surrounding machinery. This convenience ensures that downtime is minimized, and maintenance costs are kept low. One of the key features of the 6002RS bearing is its precision. The bearings are manufactured to exacting standards, ensuring that they have the necessary tolerances to perform at their best. This precision allows the bearings to run smoothly and efficiently, reducing wear and tear and extending their lifespan. The 51213 bearing is a critical component in various industrial applications, including automotive, aerospace, and heavy machinery. This bearing is designed to withstand high loads and provide long-lasting performance in harsh environments. In this article, we will delve into the features, benefits, and applications of the 51213 bearing, as well as provide tips for maintenance and troubleshooting. Spherical roller bearings are a type of rolling element bearing that is widely used in various industries due to its ability to accommodate misalignment and support heavy loads. One of the critical factors that determine the performance and longevity of these bearings is their radial clearance. In this article, we will delve into the concept of radial clearance, its importance, and how it is calculated and adjusted in spherical roller bearings. In the realm of machinery and engineering, bearings are essential components that facilitate smooth and efficient motion. These devices reduce friction between moving parts, thereby extending the life of equipment and reducing maintenance costs. However, with a wide range of bearing options available in the market, choosing the right one can be a daunting task. One factor that often influences purchasing decisions is price. In this article, we will delve into the concept of low-price bearings and explore their merits, drawbacks, and considerations for use in various applications. In addition to its high load-carrying capacity, the 51118 bearing is also known for its high precision and durability. The rollers in the bearing are precision-ground to ensure smooth operation and long service life. This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common

This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common

This makes the bearing ideal for applications where high speeds and heavy loads are common This makes the bearing ideal for applications where high speeds and heavy loads are common 51118 bearing. Overall, the 6002 rz bearing is a reliable and efficient solution for a wide range of industrial applications. Its high speed capability, durability, and sealed design make it an ideal choice for machinery and equipment that requires a dependable and long-lasting bearing solution.

51118 bearing. Overall, the 6002 rz bearing is a reliable and efficient solution for a wide range of industrial applications. Its high speed capability, durability, and sealed design make it an ideal choice for machinery and equipment that requires a dependable and long-lasting bearing solution. 2. Lubrication Applying the right amount of lubricant can help extend the life of the bearings and reduce friction. However, it's essential to use the correct type and amount of lubricant to avoid overheating or other problems. Specifications of the 6302 Bearing Beyond the technical details, the catalog also presents Timken's commitment to sustainability and environmental responsibility. The company's bearings are designed with energy efficiency in mind, contributing to reduced carbon footprints in various industries. Constructed from high-quality materials, the LM501349 bearing boasts superior strength and resilience. It typically consists of a hardened steel outer race, an inner race, and precision-rolled balls that glide effortlessly within the races. The use of advanced manufacturing techniques ensures minimal tolerances, enhancing its accuracy and reliability. The 61908 bearing, classified as a deep groove ball bearing, is a standard part in numerous industrial applications. Its dimensions, with an inner diameter of 40mm, outer diameter of 68mm, and a width of 15mm, make it suitable for compact and high-speed machinery. This particular size and design enable it to handle both radial and axial loads, contributing to its versatility in various industries. One of the most fascinating aspects of cryptography is its ability to evolve and adapt to new threats. As technology advances, so too do the methods used by attackers to compromise secure communications. This constant battle between cryptographers and hackers has led to the development of some of the most sophisticated encryption techniques known to man. Overall, the 6312 bearing size is a versatile and reliable component that plays a crucial role in the smooth operation of many types of machinery and equipment. Its compact size, high load capacity, and durability make it a popular choice for various industrial applications. By choosing the right bearing size and ensuring proper installation and maintenance, businesses can maximize the efficiency and performance of their equipment for years to come. Furthermore, the sealed design also extends the service life of the bearing. By maintaining a consistent supply of lubricant and preventing contamination, it minimizes wear and tear, thus prolonging the time between overhauls. This not only reduces downtime but also contributes to overall cost savings for the user. 1. Regular inspection Bearings should be inspected regularly for any signs of wear, damage, or abnormalities. This helps in identifying potential problems early and taking preventive measures. The design of the 29675 bearing likely incorporates refined geometries that optimize contact surfaces between the inner and outer rings and the rolling elements. Such precision engineering reduces friction coefficients, leading to increased rotational speeds and energy efficiency. In applications where every watt of power counts, this bearing could be a game-changer In applications where every watt of power counts, this bearing could be a game-changer

In applications where every watt of power counts, this bearing could be a game-changer In applications where every watt of power counts, this bearing could be a game-changer

In applications where every watt of power counts, this bearing could be a game-changer In applications where every watt of power counts, this bearing could be a game-changer 29675 bearing.

29675 bearing.  They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle

They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads. Materials for High Temperature Bearings Bearing 29424 is a type of thrust spherical roller bearing that is designed to handle heavy axial loads. It consists of two symmetrical spherical roller raceways and a common spherical raceway on the outer ring. This unique design allows the bearing to accommodate misalignment and axial deflection, making it ideal for applications where high axial loads and shock loads are present. Applications

ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads. Materials for High Temperature Bearings Bearing 29424 is a type of thrust spherical roller bearing that is designed to handle heavy axial loads. It consists of two symmetrical spherical roller raceways and a common spherical raceway on the outer ring. This unique design allows the bearing to accommodate misalignment and axial deflection, making it ideal for applications where high axial loads and shock loads are present. Applications In summary, angular contact ball bearings are precision bearings designed to support combined radial and axial loads, provide high precision and rigidity, accommodate axial loads in one direction, operate at high speeds, and offer versatility for various industrial applications.

However, the 67048 bearing's effectiveness is not only dependent on its design but also on proper maintenance and lubrication. Regular checks for wear, debris, and proper lubrication ensure optimal performance and longevity. The 6000ZZ ball bearing employs a high-quality steel construction, providing exceptional strength and resilience under various operating conditions. The balls within the bearing are precisely engineered, allowing for minimal friction and maximum load-bearing capacity. This translates into reduced wear and tear, lower energy consumption, and a quieter operation. One of the key benefits of the 6002z bearing is its high-speed performance. The smooth rotation of the balls in the grooves allows the bearing to operate at high speeds without overheating or wearing out quickly. This makes it ideal for use in machinery and equipment that require fast and efficient operation. The cage also plays a role in lubrication of the bearing. It helps to retain the lubricant within the bearing, preventing it from escaping and ensuring that the rollers are properly lubricated. This is essential for reducing friction and wear, and ensuring smooth operation of the bearing. In the realm of mechanical engineering and machinery, bearings play a pivotal role in ensuring smooth and efficient operation. Among various types of bearings, the 3 4 ID Tapered Roller Bearing stands out due to its unique design and capabilities. This article delves into the intricacies of this specific bearing type, highlighting its features, applications, and benefits. In the automotive industry, the 625ZZ finds use in engine components, power steering systems, and even electric motors. Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation

Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation ball bearing 625zz. In the field of robotics and automation, these bearings are instrumental in facilitating the precise movement of axes and gears. Angular contact ball bearings, specifically duplex designs, play a crucial role in various engineering applications where high-speed rotations and heavy loads are involved. These specialized bearings are designed to handle combined radial and axial loads, making them indispensable in industries ranging from aerospace to automotive. The L44610 Bearing A Revolutionary Component in Modern Mechanics 5. Lubrication and Maintenance Proper lubrication and maintenance are crucial for the longevity and performance of a bearing. Self-lubricating bearings, which do not require additional lubrication, are generally more expensive than those that require periodic greasing or oiling. Understanding Deep Groove Ball Thrust Bearings A Comprehensive Overview In conclusion, the ball bearing 625ZZ, though small, plays a significant role in the seamless functioning of numerous machines and devices. It embodies the principle of 'small but mighty,' demonstrating how even the tiniest components can have a profound impact on overall system performance. Its reliability, durability, and adaptability make it a staple in modern engineering, continually contributing to the advancement of technology and innovation.

ball bearing 625zz. In the field of robotics and automation, these bearings are instrumental in facilitating the precise movement of axes and gears. Angular contact ball bearings, specifically duplex designs, play a crucial role in various engineering applications where high-speed rotations and heavy loads are involved. These specialized bearings are designed to handle combined radial and axial loads, making them indispensable in industries ranging from aerospace to automotive. The L44610 Bearing A Revolutionary Component in Modern Mechanics 5. Lubrication and Maintenance Proper lubrication and maintenance are crucial for the longevity and performance of a bearing. Self-lubricating bearings, which do not require additional lubrication, are generally more expensive than those that require periodic greasing or oiling. Understanding Deep Groove Ball Thrust Bearings A Comprehensive Overview In conclusion, the ball bearing 625ZZ, though small, plays a significant role in the seamless functioning of numerous machines and devices. It embodies the principle of 'small but mighty,' demonstrating how even the tiniest components can have a profound impact on overall system performance. Its reliability, durability, and adaptability make it a staple in modern engineering, continually contributing to the advancement of technology and innovation.