Current location:

Links:

- The Impact of 32312 Bearing Prices on the Machinery Industry In addition, the 6312 zz bearing has a high load-carrying capacity, allowing it to support heavy loads without compromising performance. This makes it suitable for applications that require reliable operation under high load conditions

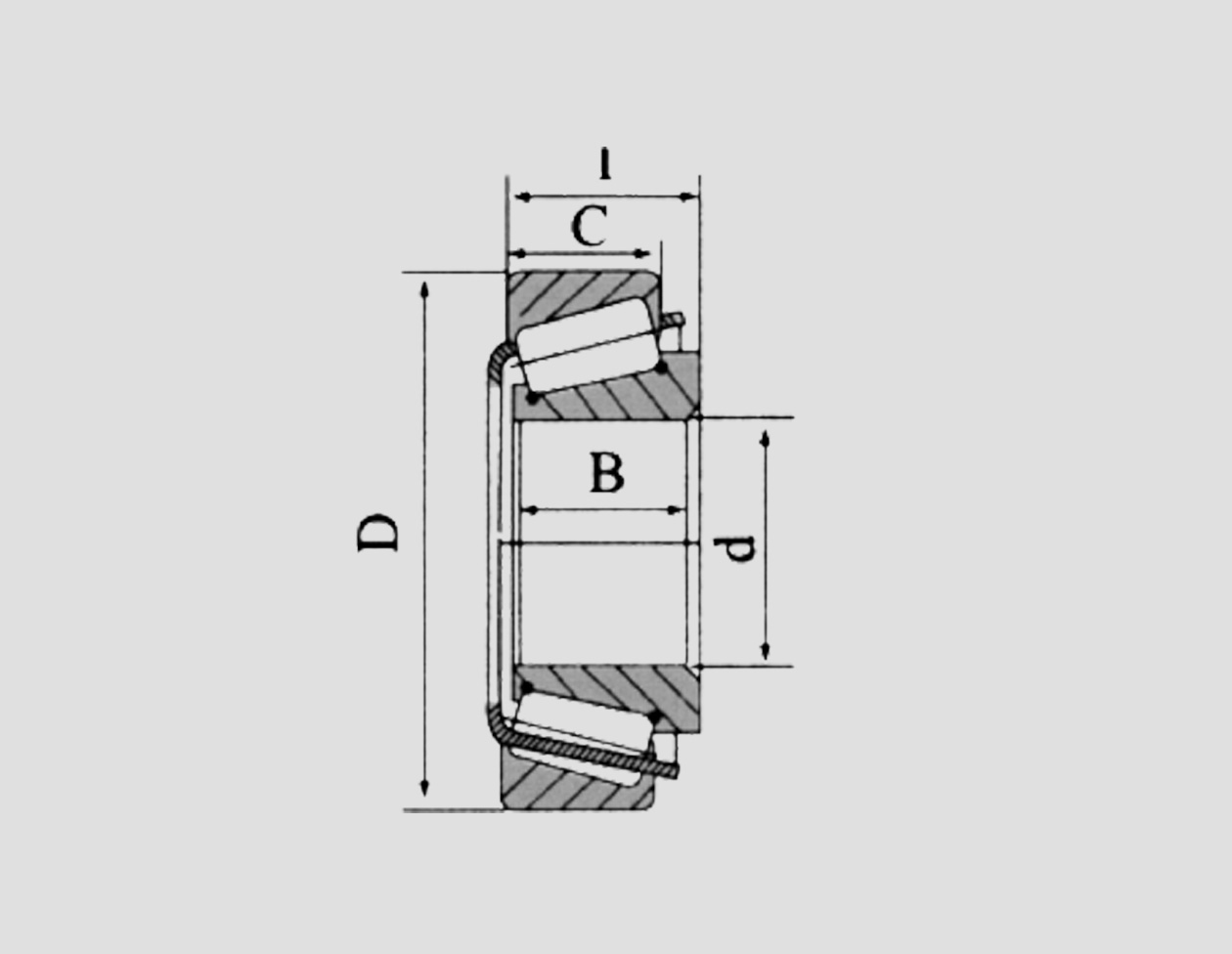

This dimension determines the height or thickness of the bearing and affects its load-carrying capacity This dimension determines the height or thickness of the bearing and affects its load-carrying capacity

This dimension determines the height or thickness of the bearing and affects its load-carrying capacity This dimension determines the height or thickness of the bearing and affects its load-carrying capacity 6014 bearing dimensions. A wider bearing can withstand higher loads, but it may also occupy more space. Therefore, it is crucial to select a bearing with an appropriate width based on the specific requirements of your application.

6014 bearing dimensions. A wider bearing can withstand higher loads, but it may also occupy more space. Therefore, it is crucial to select a bearing with an appropriate width based on the specific requirements of your application. When comparing durability, cylindrical roller bearings generally have a higher capacity for load carrying due to the larger contact patch between the roller and races Today, bearings are designed and manufactured using cutting-edge technologies and materials. Ceramic bearings, for example, offer superior hardness, thermal stability, and resistance to corrosion, making them ideal for high-speed and high-temperature applications. Magnetic bearings, on the other hand, use magnetic fields to levitate the rotating component, eliminating contact and reducing friction to virtually zero. These advanced bearings are、。 The fundamental principle behind an axial angular contact ball bearing lies in its unique construction. It consists of a series of balls nestled between two raceways, with one inner and one outer ring. The key feature that sets it apart is the angle at which the balls make contact with the raceways, typically 45 degrees. This angle enables the bearing to handle both axial and radial forces simultaneously, optimizing performance and efficiency. 4. Reduced Maintenance Costs The low maintenance requirements of self-aligning tapered roller bearings result in lower operating costs over the lifetime of the equipment.

6kN to 706kN to 70

6kN to 706kN to 70 ball bearing 6300.4kN. The temperature range for these bearings is -30°C to +120°C. * Regularly inspect the bearing for any signs of wear or damage, such as cracks, pitting, or excessive wear. In conclusion, deep groove ball bearings, with their robust design and versatility, have become indispensable in modern engineering. Their continued evolution, driven by advancements in materials science and manufacturing techniques, promises even higher performance and durability in the future. Despite their simplicity, these bearings play a pivotal role in the efficient functioning of numerous devices and systems, making them a cornerstone of mechanical engineering. * Consumer electronics Smaller bearings like the 6205 are used in consumer electronics devices such as laptops, gaming consoles, and cameras to reduce friction and improve performance. The 592A bearing is a vital component in many industrial and mechanical systems, providing reliable support and reducing rotational friction. By understanding its design, functionality, and maintenance practices, users can ensure optimal performance and extend the life of this crucial component. With proper care and attention, the 592A bearing can continue to serve its purpose for years to come. When discussing thrust bearings by size, it's crucial to understand that size isn't just about aesthetics; it directly impacts performance and application suitability. Thrust bearings come in various sizes, ranging from miniature to large-scale, each tailored to specific industrial requirements. Miniature thrust bearings, for instance, find extensive use in compact devices like cameras or watches, where space is limited yet precise movement is demanded. Their small size allows them to fit into tight spaces while providing reliable support. One of the key advantages of tapered thrust bearings is their ability to accommodate misalignment. This is particularly useful in applications where the shaft may experience slight misalignment due to manufacturing tolerances or thermal expansion. By allowing for some movement, tapered bearings can maintain stability and reduce wear on other components. * Plastic Plastic bearings are lightweight, low friction, and corrosion-resistant In conclusion, proper installation of taper roller bearings is essential for optimal performance and longevity. By following the step-by-step procedure outlined in this article, you can ensure that your taper roller bearings are installed correctly and will provide reliable service in your application. If you encounter any difficulties during the installation process, consult the bearing manufacturer's instructions or seek assistance from a qualified technician. Understanding Bearing Dimensions for 61800 Series Another point of distinction is their tolerance for misalignment. While both types have some tolerance, Deep Groove Ball Bearings are generally more forgiving, allowing for slight angular misalignments between the shaft and housing. This feature makes them more adaptable to installations where perfect alignment may be challenging. Radial clearance can be adjusted by changing the interference fit between the bearing and the housing. This can be achieved by selecting bearings with different internal clearances or by shimming the bearing housing. However, it is essential to ensure that the adjusted clearance falls within the recommended range for the specific application to avoid potential issues such as increased noise, reduced load capacity, and shortened bearing life. Introduction One of the key advantages of cylindrical roller bearings is their ability to accommodate both radial and axial loads. This makes them ideal for applications where the shaft or housing undergoes significant misalignment or dynamic loads. The rollers are designed to distribute the load evenly across the bearing surface, reducing friction and wear. Features of the 25877 Bearing The 6807 bearing is a commonly used ball bearing that offers high precision and reliability in various applications. This article aims to provide a comprehensive guide to the dimensions of the 6807 bearing, including its inner diameter, outer diameter, width, and other critical specifications. Understanding these dimensions is essential for selecting the right bearing for your specific needs and ensuring optimal performance. Cylindrical roller bearings are popular components used in various industries due to their unique design and functionality. They are specifically designed to carry heavy radial loads while being able to accommodate misalignment and shaft deflection. In this article, we will discuss the advantages and disadvantages of cylindrical roller bearings. Lastly, brand reputation and distribution channels also impact pricing. Established brands with a proven track record often command a premium due to their reliability and after-sales support. Meanwhile, purchasing through direct distributors or online platforms can sometimes offer more competitive pricing. Brand reputation is another factor to consider when assessing the price of a bearing. Established brands with a history of producing high-quality bearings may command a premium price compared to lesser-known brands

ball bearing 6300.4kN. The temperature range for these bearings is -30°C to +120°C. * Regularly inspect the bearing for any signs of wear or damage, such as cracks, pitting, or excessive wear. In conclusion, deep groove ball bearings, with their robust design and versatility, have become indispensable in modern engineering. Their continued evolution, driven by advancements in materials science and manufacturing techniques, promises even higher performance and durability in the future. Despite their simplicity, these bearings play a pivotal role in the efficient functioning of numerous devices and systems, making them a cornerstone of mechanical engineering. * Consumer electronics Smaller bearings like the 6205 are used in consumer electronics devices such as laptops, gaming consoles, and cameras to reduce friction and improve performance. The 592A bearing is a vital component in many industrial and mechanical systems, providing reliable support and reducing rotational friction. By understanding its design, functionality, and maintenance practices, users can ensure optimal performance and extend the life of this crucial component. With proper care and attention, the 592A bearing can continue to serve its purpose for years to come. When discussing thrust bearings by size, it's crucial to understand that size isn't just about aesthetics; it directly impacts performance and application suitability. Thrust bearings come in various sizes, ranging from miniature to large-scale, each tailored to specific industrial requirements. Miniature thrust bearings, for instance, find extensive use in compact devices like cameras or watches, where space is limited yet precise movement is demanded. Their small size allows them to fit into tight spaces while providing reliable support. One of the key advantages of tapered thrust bearings is their ability to accommodate misalignment. This is particularly useful in applications where the shaft may experience slight misalignment due to manufacturing tolerances or thermal expansion. By allowing for some movement, tapered bearings can maintain stability and reduce wear on other components. * Plastic Plastic bearings are lightweight, low friction, and corrosion-resistant In conclusion, proper installation of taper roller bearings is essential for optimal performance and longevity. By following the step-by-step procedure outlined in this article, you can ensure that your taper roller bearings are installed correctly and will provide reliable service in your application. If you encounter any difficulties during the installation process, consult the bearing manufacturer's instructions or seek assistance from a qualified technician. Understanding Bearing Dimensions for 61800 Series Another point of distinction is their tolerance for misalignment. While both types have some tolerance, Deep Groove Ball Bearings are generally more forgiving, allowing for slight angular misalignments between the shaft and housing. This feature makes them more adaptable to installations where perfect alignment may be challenging. Radial clearance can be adjusted by changing the interference fit between the bearing and the housing. This can be achieved by selecting bearings with different internal clearances or by shimming the bearing housing. However, it is essential to ensure that the adjusted clearance falls within the recommended range for the specific application to avoid potential issues such as increased noise, reduced load capacity, and shortened bearing life. Introduction One of the key advantages of cylindrical roller bearings is their ability to accommodate both radial and axial loads. This makes them ideal for applications where the shaft or housing undergoes significant misalignment or dynamic loads. The rollers are designed to distribute the load evenly across the bearing surface, reducing friction and wear. Features of the 25877 Bearing The 6807 bearing is a commonly used ball bearing that offers high precision and reliability in various applications. This article aims to provide a comprehensive guide to the dimensions of the 6807 bearing, including its inner diameter, outer diameter, width, and other critical specifications. Understanding these dimensions is essential for selecting the right bearing for your specific needs and ensuring optimal performance. Cylindrical roller bearings are popular components used in various industries due to their unique design and functionality. They are specifically designed to carry heavy radial loads while being able to accommodate misalignment and shaft deflection. In this article, we will discuss the advantages and disadvantages of cylindrical roller bearings. Lastly, brand reputation and distribution channels also impact pricing. Established brands with a proven track record often command a premium due to their reliability and after-sales support. Meanwhile, purchasing through direct distributors or online platforms can sometimes offer more competitive pricing. Brand reputation is another factor to consider when assessing the price of a bearing. Established brands with a history of producing high-quality bearings may command a premium price compared to lesser-known brands

22326 bearing price. However, it is essential to weigh the cost against the quality and reliability of the bearing to ensure a good value for money. In industrial applications, thin tapered roller bearings find extensive use in automotive, aerospace, mining, and heavy machinery industries

thin tapered roller bearings. In vehicles, they support the wheel hub, ensuring smooth and safe operation. In aerospace, their compact size and high-load capacity make them suitable for engine and landing gear systems. For mining and heavy equipment, they withstand harsh conditions while handling massive loads.

thin tapered roller bearings. In vehicles, they support the wheel hub, ensuring smooth and safe operation. In aerospace, their compact size and high-load capacity make them suitable for engine and landing gear systems. For mining and heavy equipment, they withstand harsh conditions while handling massive loads. The size chart typically includes the following information Other Dimensions and Specifications Specifications of the 638 ZZ Bearing

6312 zz bearing. In conclusion, India's production of the D-5 thrust ball bearing is a testament to the country's manufacturing capabilities and commitment to quality. With its high performance, durability, and reliability, the D-5 thrust ball bearing is a sought-after product in the global market and a key component in many industrial applications. Understanding the Intricacies of Bearing Dimensions One of the key advantages of the 6312 bearing size is its versatility and durability. Deep groove ball bearings like the 6312 model are known for their high load-carrying capacity and long service life. This makes them ideal for heavy-duty applications where reliability and performance are critical. The 6312 bearing size is also relatively easy to install and maintain, which helps reduce downtime and maintenance costs

6312 bearing size. In addition to its performance benefits, the 6002zz ball bearing is also easy to install and maintain

ball bearing 6002zz. With its standardized dimensions and simple design, it can be quickly and easily replaced when needed, minimizing downtime and reducing maintenance costs. Deep groove ball bearings like the 6001 Z are widely used in various industries due to their versatility and durability. They find application in motors, pumps, fans, compressors, bicycles, and even in the precision machinery of watches. Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable

ball bearing 6002zz. With its standardized dimensions and simple design, it can be quickly and easily replaced when needed, minimizing downtime and reducing maintenance costs. Deep groove ball bearings like the 6001 Z are widely used in various industries due to their versatility and durability. They find application in motors, pumps, fans, compressors, bicycles, and even in the precision machinery of watches. Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable

Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable Their ability to handle combined loads, high speed rotations, and provide smooth and low friction motion makes them indispensable bearing 6001 z.

bearing 6001 z.