Links:

The benefits of metal mesh gratings are manifold. Firstly, their durability is a standout feature. Constructed from high-quality metals, these gratings are resistant to corrosion, weathering, and physical wear, making them suitable for both indoor and outdoor applications. This longevity translates to lower maintenance costs and reduced replacement frequency, which is a significant advantage for businesses operating within tight budgets.

갈바나이즈드 금속 그레이트는 또한 미적 측면에서도 장점이 있습니다. 현대적인 디자인과 깔끔한 외관으로 인해 많은 건축가와 디자이너들이 선호하는 소재입니다. 그레이트의 통풍 구조는 공간의 쾌적함을 높여주고, 실내외의 디자인에 자연스럽게 어우러질 수 있도록 도와줍니다.

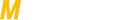

galvanised metal grate

Yhteenvetona voidaan todeta, että kevyet kävelytiet ja ritilät tarjoavat useita etuja, jotka tekevät niistä erinomaisen vaihtoehdon monenlaisille rakennus- ja infraprojekteille. Ne ovat kestäviä, turvallisia ja esteettisiä, mikä tekee niistä täydellisen valinnan moderniin ympäristöön.

Extended service life.

یکی از نکات مهم در انتخاب شبکههای فلزی، توجه به مشخصات فنی آنها است. شبکههای فلزی با طراحیها و ابعاد مختلفی در بازار وجود دارند که هر کدام مناسب کاربرد خاصی هستند. به عنوان مثال، شبکههای با چشمههای بزرگتر معمولاً برای کاربردهای صنعتی و شبکههای با چشمههای کوچکتر برای پروژههای ساختمانی مناسبتر هستند.

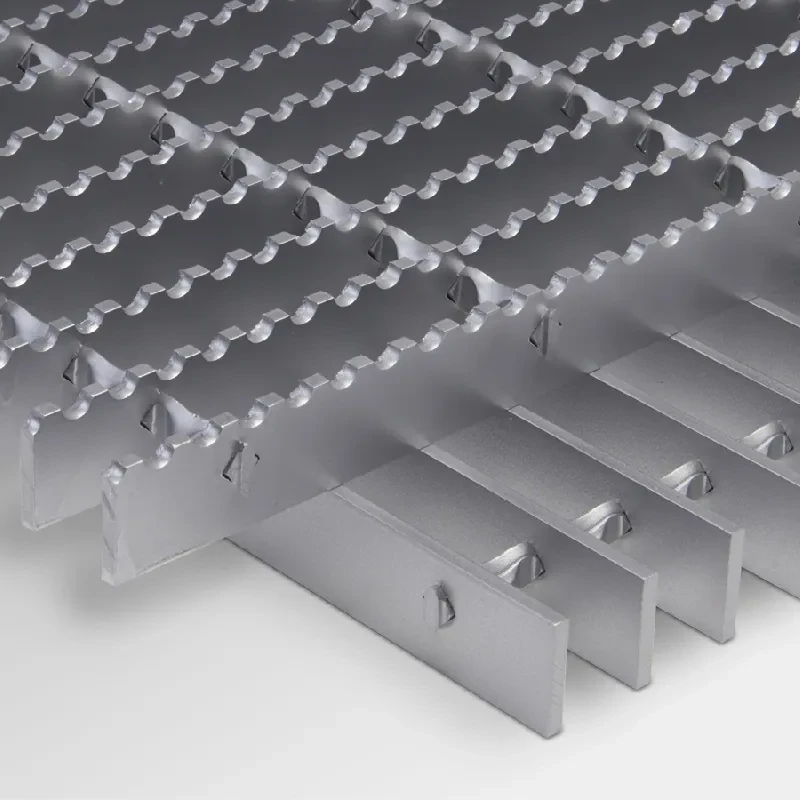

metal grating for sale

1. Standard-Gitterroste Diese sind am weitesten verbreitet und werden oft in Industriebauten, Fußgängerwegen und als Abdeckungen für Gräben verwendet.

steel grating sizes

4. Pazar Koşulları Çelik fiyatları ve talep durumu, galvanizli ızgaraların maliyetlerini etkileyen önemli ekonomik faktörlerdir. Piyasa dalgalanmaları, fiyatların yükselmesine veya düşmesine neden olabilir. Bu nedenle, projeye başlanmadan önce güncel pazar koşullarını göz önünde bulundurmak önemlidir.

Installasjonen av tykkfarget sveiset stangrist er også enkel og effektiv. Den kan tilpasses ulike bygningstyper og er lett å montere på både nye og eksisterende strukturer. Dette gir fleksibilitet i design og gjør det bedre egnet for prosjekter med spesifikke krav. I tillegg kommer stangristen i forskjellige dimensjoner og mønstre, noe som gir mulighet for kreativ tilpasning i utforming og estetikk.

heavy-duty welded bar grating

Steel grating is a flat product made by welding or integrating bars or plates in a specific pattern. The openings in the grating allow for light, air, and water to pass through, making it suitable for environments like factories, parking structures, and outdoor spaces. The applications range from flooring to drainage covers and safety barriers.

La instalación de rejillas de acero mild también es relativamente sencilla, lo que reduce el tiempo y el costo de la obra. Debido a su peso y formato, se pueden manejar fácilmente, facilitando su colocación en el lugar deseado. Esto minimiza los tiempos de inactividad y maximiza la eficiencia en la construcción o el mantenimiento de instalaciones.

De toepassingen van shaker screens zijn divers. In de olie- en gasindustrie worden zij vaak gebruikt om boorslib te scheiden van geproduceerde vloeistoffen. Dit is cruciaal om schade aan de boorinstallaties te voorkomen en om een efficiënte winning van mineralen en energiebronnen te waarborgen. In de mijnbouw helpen shaker screens bij het scheiden van ertsen van onzuiverheden, waardoor het productieproces wordt geoptimaliseerd en de kwaliteit van het eindproduct verbetert.

shaker screen

Kortom, shaker screens zijn onmisbare hulpmiddelen in de moderne industrie. Ze verbeteren niet alleen de efficiëntie van productieprocessen, maar dragen ook bij aan duurzaamheid en milieuvriendelijke praktijken. Met de voortdurende ontwikkeling van technologieën blijven deze apparaten evolueren, wat nieuwe mogelijkheden biedt voor zowel economische groei als milieubehoud. Bedrijven die investeren in hoogwaardige shaker screens en de bijbehorende technologieën, zullen ongetwijfeld een voorsprong hebben in de steeds competitievere markten van vandaag.

Tot slot zijn gelaste staalroosters ook een milieuvriendelijke keuze. Staal is 100% recyclebaar, wat betekent dat het product aan het einde van zijn levensduur opnieuw kan worden verwerkt zonder verlies van kwaliteit. Dit draagt bij aan een circulaire economie en helpt bedrijven om hun ecologische voetafdruk te verminderen.

Selecting the appropriate thickness of steel grating is crucial for ensuring the structural integrity and safety of a project. By considering factors such as load requirements, span lengths, environmental conditions, and safety regulations, engineers and designers can make informed decisions. Ultimately, the right thickness not only guarantees safety and performance but also contributes to the longevity of the structure. As the construction industry evolves, understanding the nuances of steel grating, including thickness, will remain a fundamental aspect of successful design and planning.

The hot dip galvanization process begins by cleaning the steel to remove any contaminants, such as rust, oil, or dirt. After cleaning, the steel is submerged in a bath of molten zinc at approximately 450°C (842°F). The zinc reacts with the iron in the steel to form a series of zinc-iron alloy layers, which are then topped with a corrosion-resistant zinc layer. This method not only provides a tough, protective coat but also ensures a strong bond between the coating and the steel, resulting in a longer lifespan.

ステンレス製チャンネルドレインは、現代の建築物や舗装されたエリアでの排水システムとして非常に人気があります。その優れた特性と多様な用途により、さまざまな業界で広く使用されています。この記事では、ステンレス製チャンネルドレインの特徴、利点、およびその適用例について詳しく説明します。

Sonuç olarak, havuz kenarı kuyu drenaj ızgara sistemleri, sadece suyun etkin bir şekilde yönetilmesinde değil, aynı zamanda kullanıcı konforu ve güvenliğinde de kritik bir rol oynar. Bu sistemlerin doğru bir şekilde seçilmesi ve uygulanması, havuz alanlarının daha güvenli, hoş ve kullanışlı hale gelmesini sağlar. Özellikle yaz aylarında artan havuz kullanımı ile birlikte, bu sistemlerin önemi bir kat daha artmaktadır.

One of the primary advantages of grated metal floors is their exceptional load-bearing capacity. Designed to support heavy machinery and foot traffic, these floors are ideal for industrial settings such as warehouses, factories, and manufacturing plants. The structural integrity of grated metal floors ensures that they can withstand significant weight, making them suitable for areas where heavy equipment is used. Furthermore, the open design facilitates easy movement of air, reducing issues related to heat accumulation and humidity.

Stålristens tykkelse En vigtig faktor for holdbarhed og anvendelse

The hot dip galvanization process begins by cleaning the steel to remove any contaminants, such as rust, oil, or dirt. After cleaning, the steel is submerged in a bath of molten zinc at approximately 450°C (842°F). The zinc reacts with the iron in the steel to form a series of zinc-iron alloy layers, which are then topped with a corrosion-resistant zinc layer. This method not only provides a tough, protective coat but also ensures a strong bond between the coating and the steel, resulting in a longer lifespan.

Hot dip galvanized steel grating has garnered significant attention across various industries due to its exceptional durability and anti-corrosive properties. This versatile material is widely used in applications ranging from industrial flooring to walkways and drainage covers. Understanding the manufacturing process, benefits, and applications of hot dip galvanized steel grating can provide valuable insights for engineers, construction professionals, and facility managers.

Understanding Floor Grating Prices Factors, Options, and Trends