Current location:

Links:

-

Screws, nails, and clamps are the unsung heroes of formwork construction. They hold the formwork together securely, ensuring stability during the pouring process They hold the formwork together securely, ensuring stability during the pouring process

They hold the formwork together securely, ensuring stability during the pouring process They hold the formwork together securely, ensuring stability during the pouring process

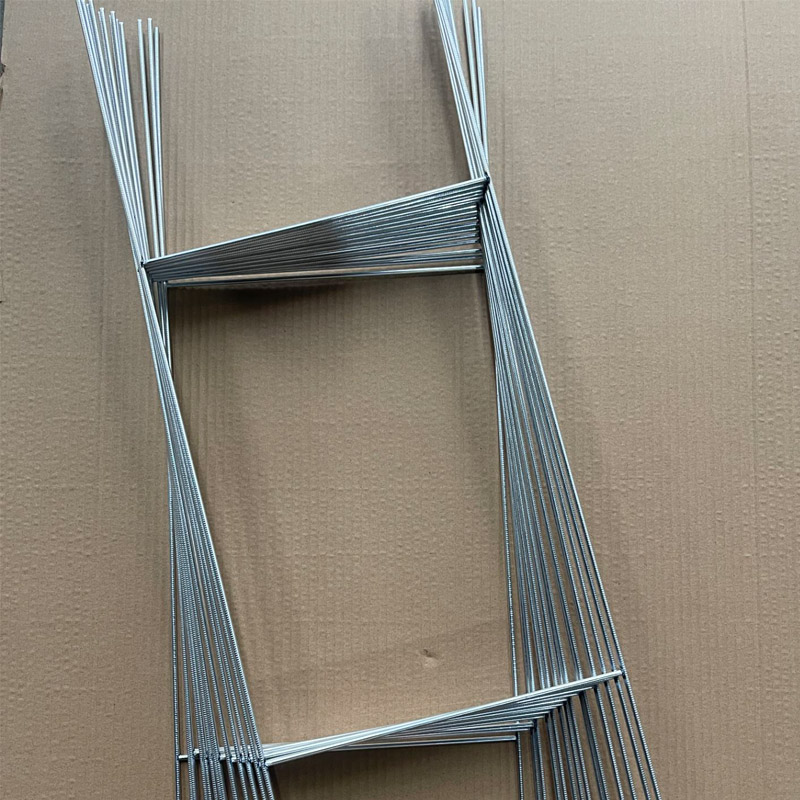

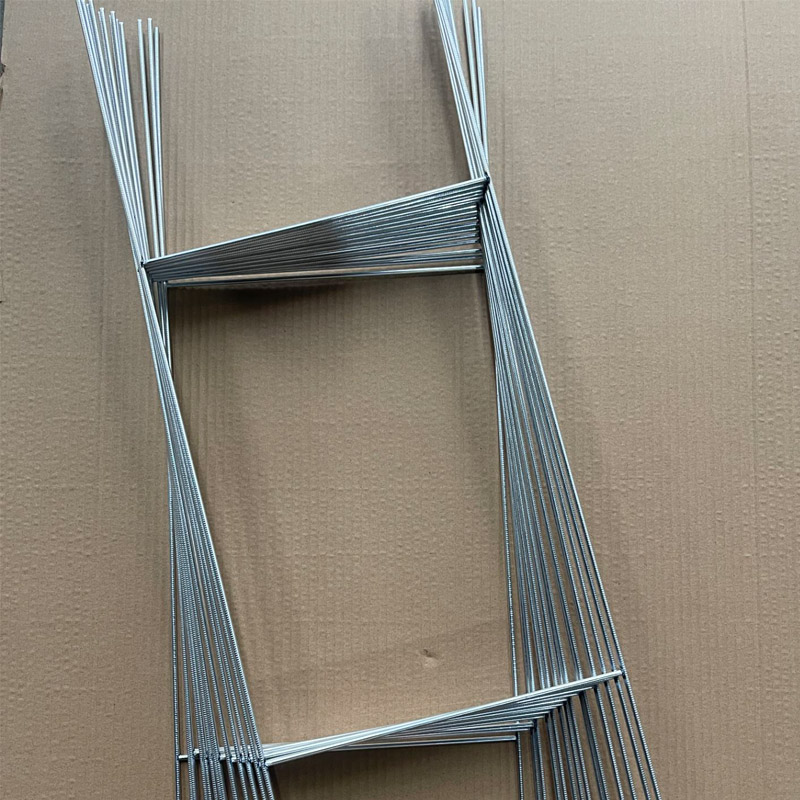

They hold the formwork together securely, ensuring stability during the pouring process They hold the formwork together securely, ensuring stability during the pouring process concrete formwork accessories. Meanwhile, anchor bolts keep the formwork in place, preventing any movement that could compromise the concrete's shape. Furthermore, in the context of greenhouse construction, strong garden wire is often used to reinforce the frame, ensuring stability and longevity. It can also be employed to create DIY garden tools, like tomato stakes or plant supports, demonstrating its versatility and cost-effectiveness. Molding accessories like falsework and shores are also indispensable. Falsework supports the formwork until the concrete sets, while shores, or props, provide additional support to prevent the formwork from collapsing under the weight of the wet concrete. The concept of masonry ties is rooted in ancient building practices where builders recognized the need for reinforcement to prevent walls from buckling or shifting under pressure. As architecture evolved, so did the methods to ensure its stability. By the 19th century, with the advent of industrialization, the production of iron and later steel became more prevalent, making these materials accessible for widespread use in construction. Don't settle for a mediocre field fence when you can have one that enhances the security and beauty of your property. Contact us today to learn more about our field fences for sale and to schedule your consultation. We look forward to helping you find the perfect fence for your needs! The versatility of diamond wire mesh extends to the art world too. Artists have incorporated it into sculptures and installations, exploiting its geometric beauty and structural resilience to create striking pieces. In agriculture, galvanized wire fence is widely used for livestock containment due to its strength and flexibility. It can be easily shaped and configured to suit different topographies, making it suitable for both flat and hilly terrains. The wire's spacing can be customized to accommodate various animals, from sheep and goats to larger cattle, while still providing a secure barrier. Lastly, plant cages and supports add a touch of personality to any room. They come in a variety of styles and designs, so you can choose one that complements your home decor. Whether you prefer a modern, minimalist look or something more ornate and traditional, there is sure to be a cage or support that suits your taste. Flat wire springs can be classified into several types based on their shape, size, and application. Some of the most common types include Plastering Corner Bead A Crucial Element in Drywall Construction One of the main advantages of rebar positioners is their ability to improve the efficiency and accuracy of the construction process. By securely holding the rebar in place, these tools help to ensure that the reinforcement bars are properly aligned and spaced according to the design specifications. This, in turn, helps to prevent potential issues such as structural weakness or cracking in the finished concrete structure.

concrete formwork accessories. Meanwhile, anchor bolts keep the formwork in place, preventing any movement that could compromise the concrete's shape. Furthermore, in the context of greenhouse construction, strong garden wire is often used to reinforce the frame, ensuring stability and longevity. It can also be employed to create DIY garden tools, like tomato stakes or plant supports, demonstrating its versatility and cost-effectiveness. Molding accessories like falsework and shores are also indispensable. Falsework supports the formwork until the concrete sets, while shores, or props, provide additional support to prevent the formwork from collapsing under the weight of the wet concrete. The concept of masonry ties is rooted in ancient building practices where builders recognized the need for reinforcement to prevent walls from buckling or shifting under pressure. As architecture evolved, so did the methods to ensure its stability. By the 19th century, with the advent of industrialization, the production of iron and later steel became more prevalent, making these materials accessible for widespread use in construction. Don't settle for a mediocre field fence when you can have one that enhances the security and beauty of your property. Contact us today to learn more about our field fences for sale and to schedule your consultation. We look forward to helping you find the perfect fence for your needs! The versatility of diamond wire mesh extends to the art world too. Artists have incorporated it into sculptures and installations, exploiting its geometric beauty and structural resilience to create striking pieces. In agriculture, galvanized wire fence is widely used for livestock containment due to its strength and flexibility. It can be easily shaped and configured to suit different topographies, making it suitable for both flat and hilly terrains. The wire's spacing can be customized to accommodate various animals, from sheep and goats to larger cattle, while still providing a secure barrier. Lastly, plant cages and supports add a touch of personality to any room. They come in a variety of styles and designs, so you can choose one that complements your home decor. Whether you prefer a modern, minimalist look or something more ornate and traditional, there is sure to be a cage or support that suits your taste. Flat wire springs can be classified into several types based on their shape, size, and application. Some of the most common types include Plastering Corner Bead A Crucial Element in Drywall Construction One of the main advantages of rebar positioners is their ability to improve the efficiency and accuracy of the construction process. By securely holding the rebar in place, these tools help to ensure that the reinforcement bars are properly aligned and spaced according to the design specifications. This, in turn, helps to prevent potential issues such as structural weakness or cracking in the finished concrete structure. Horizontal joint reinforcement, masonry joint reinforcement, and brick reinforcement ladders are essential techniques for ensuring the structural integrity and durability of masonry constructions. These reinforcement methods play a critical role in preventing cracks, distributing loads evenly, and enhancing the overall stability of masonry walls. By incorporating these techniques into their projects, builders can create safer, more resilient structures that stand the test of time. Understanding and utilizing these reinforcement strategies is crucial for achieving high-quality masonry construction.

However, it is crucial to consider the environmental impact of using metal stakes. While their durability reduces the need for frequent replacement, proper disposal and recycling at the end of their lifecycle is essential to minimize waste and promote sustainability. The manufacturing process for flat wire springs typically involves the following steps Lastly, excellent customer service is essential when working with any supplier. Look for suppliers who are responsive, friendly, and willing to go above and beyond to meet your needs. This will ensure that you have a positive experience throughout the purchasing process and that you're satisfied with the final product. One of the key advantages of wire shelving grids lies in their modularity. They can be easily assembled and disassembled, making them highly adaptable to changing storage needs. The grid pattern allows for custom configurations, with shelves adjustable in height to accommodate items of varying sizes. Moreover, additional accessories like drawers, hooks, and baskets can be attached to the grid system, enhancing its functionality. Galvanized wire, a product of advanced metallurgical engineering, is a versatile and robust material that has found extensive application across a myriad of industries. This unique wire, characterized by its zinc coating, offers exceptional resistance to corrosion, making it an ideal choice for numerous applications where durability and longevity are paramount. Moreover, the 3 8 compression spring is crucial in industrial machinery Additionally, coated tomato cages are easy to clean and maintain. Simply wiping them down with a damp cloth or spraying them with a hose will keep them looking good as new. This is especially important for keeping your garden looking organized and well-kept. When it comes to security and privacy, diamond mesh wire fence is a top choice for many homeowners and businesses. This type of fence offers superior strength and durability, making it an excellent investment for those who want to protect their property from unwanted intruders. In this article, we will discuss the various factors that affect the price of diamond mesh wire fence, as well as provide some tips on how to get the best deal. Understanding Timber Frame Wall Ties A Key Component in Sustainable Construction 3. Product Range Consider the range of wire mesh fencing products offered by the manufacturer. Look for manufacturers that provide a variety of options in terms of materials, sizes, designs, and finishes to suit your specific needs. In terms of filtration, the consistent pore size of the welded wire mesh makes it an excellent choice for screening and filtering applications. From pharmaceutical manufacturing, where precision separation is crucial, to agricultural uses, such as protecting crops from pests while allowing air to circulate, the mesh performs reliably under diverse requirements. Thus, when we encounter a long metal stake, let us not merely see an object; let us hear its silent song, feel its weight of history, and appreciate the myriad roles it has played in shaping our world. For in the heart of this seemingly simple artifact lies a grand symphony of human endeavor, a melody that resonates through the ages. Flat Wire Spring Manufacturers An Overview Aluminum wire, with its malleability and strength, serves as the perfect medium for creating intricate floral designs. Unlike traditional materials like silk or fresh flowers, aluminum wire allows for a level of durability that endures the test of time. Its silver sheen adds a touch of modernity and elegance to each piece, making it an ideal choice for both indoor and outdoor decorations. This is where Spring comes into play. The Spring framework is renowned for its dependency injection (DI) feature, which simplifies the process of managing dependencies between different parts of an application. By using Spring, developers can easily integrate Swing Extension components into their applications without worrying about manual instantiation and configuration. The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications

Additionally, coated tomato cages are easy to clean and maintain. Simply wiping them down with a damp cloth or spraying them with a hose will keep them looking good as new. This is especially important for keeping your garden looking organized and well-kept. When it comes to security and privacy, diamond mesh wire fence is a top choice for many homeowners and businesses. This type of fence offers superior strength and durability, making it an excellent investment for those who want to protect their property from unwanted intruders. In this article, we will discuss the various factors that affect the price of diamond mesh wire fence, as well as provide some tips on how to get the best deal. Understanding Timber Frame Wall Ties A Key Component in Sustainable Construction 3. Product Range Consider the range of wire mesh fencing products offered by the manufacturer. Look for manufacturers that provide a variety of options in terms of materials, sizes, designs, and finishes to suit your specific needs. In terms of filtration, the consistent pore size of the welded wire mesh makes it an excellent choice for screening and filtering applications. From pharmaceutical manufacturing, where precision separation is crucial, to agricultural uses, such as protecting crops from pests while allowing air to circulate, the mesh performs reliably under diverse requirements. Thus, when we encounter a long metal stake, let us not merely see an object; let us hear its silent song, feel its weight of history, and appreciate the myriad roles it has played in shaping our world. For in the heart of this seemingly simple artifact lies a grand symphony of human endeavor, a melody that resonates through the ages. Flat Wire Spring Manufacturers An Overview Aluminum wire, with its malleability and strength, serves as the perfect medium for creating intricate floral designs. Unlike traditional materials like silk or fresh flowers, aluminum wire allows for a level of durability that endures the test of time. Its silver sheen adds a touch of modernity and elegance to each piece, making it an ideal choice for both indoor and outdoor decorations. This is where Spring comes into play. The Spring framework is renowned for its dependency injection (DI) feature, which simplifies the process of managing dependencies between different parts of an application. By using Spring, developers can easily integrate Swing Extension components into their applications without worrying about manual instantiation and configuration. The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications

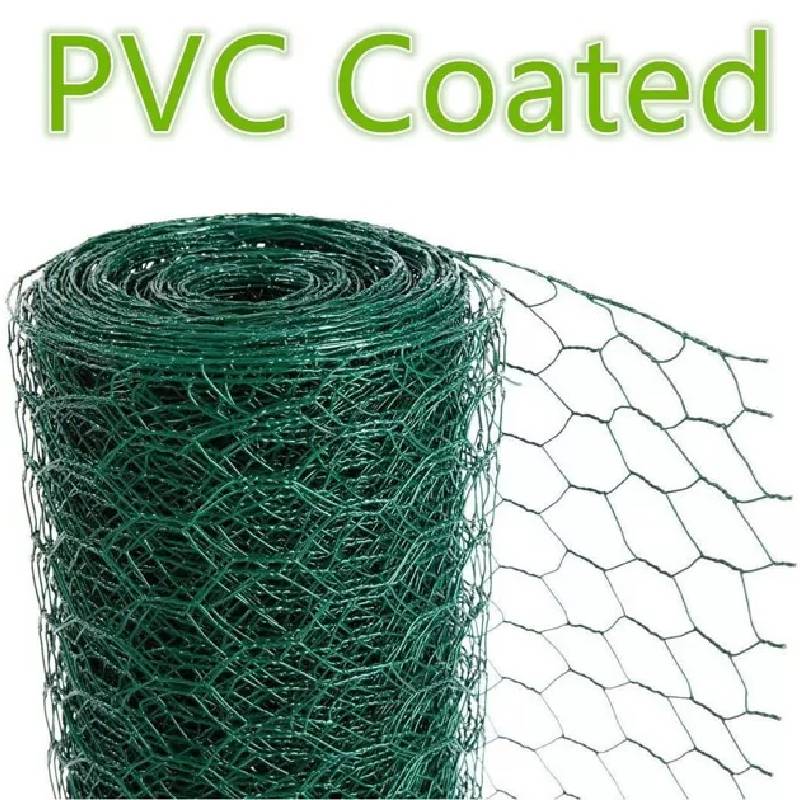

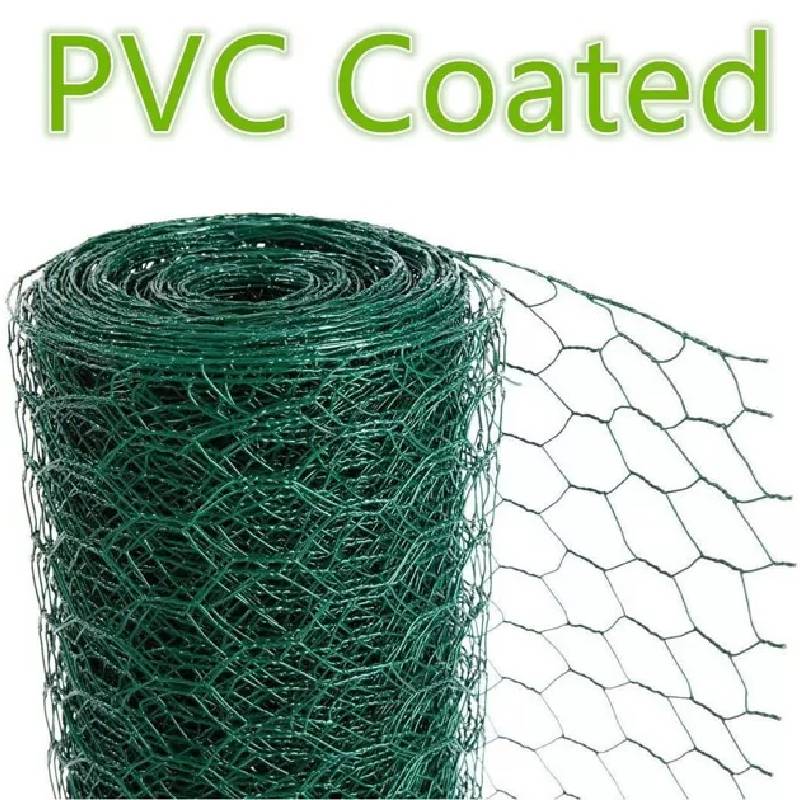

The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications swing extension spring. There are several key benefits to using steel welded wire fabric in construction projects. These include Brick masonry ties are an essential component in the construction of brick buildings. These ties play a crucial role in providing stability and strength to the structure by connecting the inner and outer wythes of brick masonry walls. 2. Versatility Coil springs can be used in a wide range of applications, making them a versatile solution for various industries. Whether you need springs for your car, truck, or motorcycle, or for industrial machinery and construction equipment, there's sure to be a coil spring that fits your needs. 1 These include In conclusion, expansion springs are a fundamental component in many mechanical and electronic systems, providing a controlled level of force and movement. Their durability, flexibility, and reliability make them a popular choice for engineers and designers looking for a versatile and effective spring solution. The primary component of welded wire mesh is steel wire, which can be galvanized, stainless, or made from other metals for specific purposes. The wires are cut and arranged in parallel rows, with a consistent spacing, and then fused together at their intersections through a welding process. This results in a grid pattern with square or rectangular openings, the size of which can vary depending on the application requirements. Why Choose Coil Springs for Sale? Maintenance Tips for 5-Inch Coil Springs Brick joint reinforcement serves as the backbone of a building's integrity. It is akin to the glue that binds the individual elements together, creating a cohesive unit that is stronger than its parts. Without proper reinforcement, even the highest-quality bricks are susceptible to cracking and crumbling under pressure. This is where the science of brick joint reinforcement comes into play. Secondly, store your chicken wire properly after purchasing. Chicken wire can be damaged if it is exposed to extreme temperatures or moisture, so it's important to store it in a dry, cool place. You may also want to consider using plastic sheeting or tarps to protect your chicken wire from the elements. Joint reinforcement is a critical component in masonry construction that helps to enhance the structural integrity and overall performance of a building. In masonry walls, joints are the spaces between bricks, blocks, or stones that are filled with mortar to create a solid structure. Joint reinforcement, such as metal or synthetic materials, is placed within these joints to provide additional support and stability. In addition to spacing, it is important to use the correct type and size of cavity wall ties for the specific building project. There are different types of cavity wall ties available, such as stainless steel, galvanized steel, and plastic wall ties, each with their own strengths and weaknesses. The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building

swing extension spring. There are several key benefits to using steel welded wire fabric in construction projects. These include Brick masonry ties are an essential component in the construction of brick buildings. These ties play a crucial role in providing stability and strength to the structure by connecting the inner and outer wythes of brick masonry walls. 2. Versatility Coil springs can be used in a wide range of applications, making them a versatile solution for various industries. Whether you need springs for your car, truck, or motorcycle, or for industrial machinery and construction equipment, there's sure to be a coil spring that fits your needs. 1 These include In conclusion, expansion springs are a fundamental component in many mechanical and electronic systems, providing a controlled level of force and movement. Their durability, flexibility, and reliability make them a popular choice for engineers and designers looking for a versatile and effective spring solution. The primary component of welded wire mesh is steel wire, which can be galvanized, stainless, or made from other metals for specific purposes. The wires are cut and arranged in parallel rows, with a consistent spacing, and then fused together at their intersections through a welding process. This results in a grid pattern with square or rectangular openings, the size of which can vary depending on the application requirements. Why Choose Coil Springs for Sale? Maintenance Tips for 5-Inch Coil Springs Brick joint reinforcement serves as the backbone of a building's integrity. It is akin to the glue that binds the individual elements together, creating a cohesive unit that is stronger than its parts. Without proper reinforcement, even the highest-quality bricks are susceptible to cracking and crumbling under pressure. This is where the science of brick joint reinforcement comes into play. Secondly, store your chicken wire properly after purchasing. Chicken wire can be damaged if it is exposed to extreme temperatures or moisture, so it's important to store it in a dry, cool place. You may also want to consider using plastic sheeting or tarps to protect your chicken wire from the elements. Joint reinforcement is a critical component in masonry construction that helps to enhance the structural integrity and overall performance of a building. In masonry walls, joints are the spaces between bricks, blocks, or stones that are filled with mortar to create a solid structure. Joint reinforcement, such as metal or synthetic materials, is placed within these joints to provide additional support and stability. In addition to spacing, it is important to use the correct type and size of cavity wall ties for the specific building project. There are different types of cavity wall ties available, such as stainless steel, galvanized steel, and plastic wall ties, each with their own strengths and weaknesses. The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building

The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building The size of the cavity wall ties should also be carefully chosen based on the load-bearing requirements of the building cavity wall ties spacing.

cavity wall ties spacing. Concrete Accessories Suppliers

In the realm of home decor and interior design, metal grid wall shelves have emerged as a trendy and functional element that effortlessly combines form and function. These shelves, characterized by their open-grid structure made of metal, offer a unique aesthetic appeal while serving as practical storage solutions.Price is always an important factor when it comes to purchasing any product, including welded mesh fencing. Look for suppliers who offer competitive pricing without sacrificing quality. You can compare prices from different suppliers to find the best deal, but make sure to prioritize quality over price. External corner plaster beads are an essential component in the construction and finishing of exterior corners in buildings. They provide a clean and professional look while also adding durability and protection to the corners of a structure. The 200mm cavity wall also offers acoustic advantages. The separation between the two leaves dampens sound transmission, providing a quieter living or working environment. Additionally, it provides a degree of fire resistance, as the cavity can inhibit the spread of flames between rooms or floors. Square metal grid panels, an architectural and engineering marvel, have become an integral part of modern design aesthetics and functionality across various industries. These versatile structures, characterized by their distinct square-shaped grid pattern, offer a harmonious blend of strength, durability, and visual appeal. The manufacturing sector also relies on galvanized wire

galvanized wire for sale. In the production of wire ropes, springs, and various hardware items, galvanized wire offers a balance between strength, flexibility, and corrosion resistance. It's also a popular choice for electrical grounding and cable assemblies due to its conductivity properties.

galvanized wire for sale. In the production of wire ropes, springs, and various hardware items, galvanized wire offers a balance between strength, flexibility, and corrosion resistance. It's also a popular choice for electrical grounding and cable assemblies due to its conductivity properties. In modern construction practices, cavity wall ties are installed at regular intervals along the length of the wall. The spacing and size of the ties may vary depending on factors such as the height of the building, the type of masonry materials used, and environmental conditions. It is important to follow industry best practices and guidelines when installing cavity wall ties to ensure optimal performance and longevity. Once all of the necessary calculations have been completed, engineers can compile their design data into a PDF file for reference. This document serves as a comprehensive record of the design process, including all of the calculations, data inputs, and assumptions that were used to create the final spring design. By documenting the design calculations in a PDF file, engineers can easily share their work with colleagues and collaborators, as well as refer back to the information at a later date if needed.