Links:

The different grades of HPMC offer a wide range of functionalities tailored to meet the needs of various industries. By understanding the characteristics and applications of each grade, manufacturers can select the most appropriate type for their specific formulations. As research and development in this field continue, the versatility of HPMC will likely expand, leading to new and innovative applications across an even broader range of sectors.

Die Eigenschaften von HPMC sind entscheidend für seine Funktionalität. Es hat eine hohe Wasserbindungsfähigkeit und kann daher in Formulierungen eingesetzt werden, um die Feuchtigkeit zu erhalten. Dies ist besonders wichtig in der Kosmetikindustrie, wo Feuchtigkeit eine Schlüsselrolle für die Wirksamkeit von Hautpflegeprodukten spielt. Darüber hinaus sorgt HPMC für eine glatte Textur und verbessert die Verteilbarkeit von Cremes und Gelen.

Agriculture: In the field of agriculture, hydroxyethyl cellulose can be used for soil improvement and fertilizer efficiency enhancement.

2. Extended Open Time

The diverse applications of Hydroxypropyl Methylcellulose highlight its significance in various industries. Its unique physicochemical properties make it a valuable ingredient in pharmaceuticals, food, cosmetics, and construction. As industries continue to innovate, the demand for HPMC is likely to grow, further solidifying its role as a key component in modern formulations. Whether enhancing the quality of health products, improving food textures, or ensuring the efficiency of construction materials, HPMC stands out as a remarkable substance that contributes to the advancement of technology and consumer satisfaction.

The construction industry has also embraced HPMC due to its properties that enhance mortar and plaster formulations. It improves workability and extend open time, allowing for better application and flexibility in various weather conditions. Moreover, HPMC helps in reducing segregation and improves adhesion, crucial for ensuring the durability of structures.

Applications

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer derived from cellulose, a natural polymer obtained from plant cell walls. The chemical modifications that HPMC undergoes enable it to possess unique properties, making it a valuable ingredient across various industries, including pharmaceuticals, food, cosmetics, and construction. This article explores the multifaceted uses of HPMC and highlights its significance in modern applications.

.

Applications in Pharmaceuticals

Hydroxypropyl methyl cellulose is a crucial ingredient across numerous industries due to its multifunctional properties. From pharmaceuticals to food and construction, HPMC enhances product performance, stability, and consumer experience. The ongoing innovation by leading manufacturers ensures that HPMC continues to meet the diverse and changing needs of global markets. As industries evolve, the importance of HPMC and its manufacturers will undoubtedly grow, solidifying its role as an essential compound in modern applications.

1. Expansion of the Construction Industry Continuous urbanization and the expansion of infrastructure development projects globally are major factors driving the RDP market. As governments focus on building sustainable cities, the demand for innovative construction materials that enhance performance and reduce environmental impact is on the rise.

2. Hydroxyethyl Cellulose Has the Use of Adhesives and Binders

Conclusion

HPMC-nin ətraf mühitə olan təsiri də müsbət olaraq qiymətləndirilir. Biodegradebilə bilən bir maddədir, bu da onun ekoloji cəhətdən dostluq təşkil etməsini təmin edir. Beləliklə, hidroksipropil metil sellüloza, istifadə sahələrinin genişliyi və çevikliyilə müasir iqtisadiyyatın əsas tərkib hissələrindən biri halına gəlmişdir.

In the pharmaceutical sector, HPMC is predominantly used as a binder, thickening agent, and drug release modifier. Its ability to form gels upon heating allows for controlled drug release mechanisms, which are critical in designing sustained-release formulations. HPMC is also employed in the manufacturing of tablets, where it acts as a binding agent, ensuring the integrity of the tablet during the compression process.

Redispersible polymer powder (RDP) has emerged as an essential ingredient in various industries, particularly in construction, coatings, and adhesives. These polymer powders are typically derived from emulsions and are designed to improve the performance characteristics of end products. As with any commodity, the price of redispersible polymer powder is influenced by a myriad of factors that vary across different markets and applications.

Redisperzibilní polymerový prášek z Číny Inovace v stavebních materiálech

In conclusion, the properties of HPMC—its water retention, rheological behavior, film-forming ability, and eco-friendliness—make it a valuable component across various industries. As innovation continues to advance, the applications and benefits of HPMC are likely to expand, reinforcing its integral role in modern formulations and products.

In construction, HPMC is included in cement and plaster formulations, improving workability and extending open time. Its water retention properties help ensure that these materials remain workable for longer periods, facilitating easier application and enhancing bonding.

Utilisation de l'HPMC Un polymère polyvalent aux multiples applications

2. Thickening Agent In liquid formulations, such as syrups and suspensions, HPMC serves as a thickening agent. Its capacity to increase viscosity without significantly altering the taste or deliverability of the product is highly advantageous in creating pleasant and effective medicinal syrups.

Hypromellose (HPMC) A Versatile Polymer in Pharmaceutical and Technical Applications

4. Cosmetics and Personal Care HPMC is used in a variety of personal care products, where it enhances stability and consistency in creams, lotions, and gels.

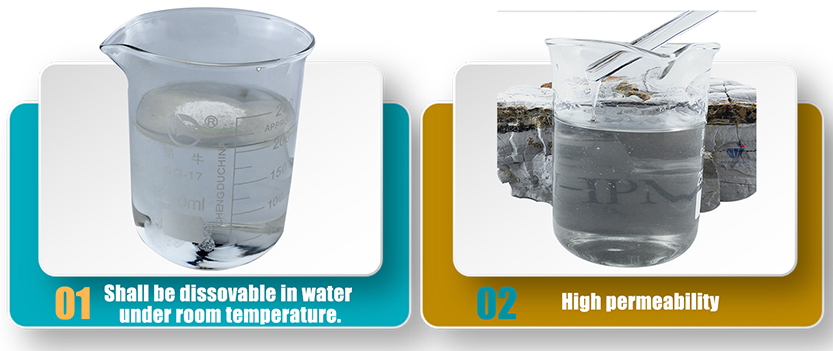

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer derived from cellulose, which is a natural polymer present in the cell walls of plants. This modified cellulose has gained significant attention in various industries due to its unique properties and functionality. HPMC is primarily used as a thickening agent, emulsifier, and stabilizer, making it an essential ingredient in pharmaceuticals, food products, cosmetics, and construction materials.

Hydroxyethyl cellulose không chỉ an toàn cho sức khỏe con người mà còn thân thiện với môi trường. Với khả năng hòa tan trong nước và tạo thành dung dịch có độ đặc như mong muốn, HEC là lựa chọn lý tưởng cho những ai muốn tạo ra sản phẩm chất lượng cao. Ngoài ra, HEC còn có khả năng kiểm soát độ nhớt và ổn định, giúp cải thiện tuổi thọ và chất lượng của sản phẩm.

The synthesis of HPMC involves a few critical principles. First, it is crucial to select an appropriate template molecule, which is the target substance that the polymer will remember after the synthesis process. This template is usually selected based on its chemical compatibility with the functional monomers that will be used in polymerization.

Redispersible polymer powder manufacturers play an essential role in enhancing the performance of construction materials. By providing high-quality products backed by technical expertise and innovation, these manufacturers contribute to the overall improvement of the building and construction industry. As demand for these materials continues to grow, selecting the right supplier becomes increasingly important for achieving superior results in construction projects. Understanding the key factors that define quality and performance will help businesses make informed decisions, ultimately leading to better construction practices and successful project outcomes.

Despite its many advantages, the properties of hydroxyethyl cellulose can vary significantly based on factors such as molecular weight and substitution degree. These characteristics influence performance in specific applications, necessitating careful selection based on end-use requirements. Manufacturers frequently provide different grades of HEC, allowing formulators to tailor their products to meet specific functional and performance criteria.

مىثيل گيدروكسى ايتىل سيلولوز، سۇغا قوشۇلغاندا، قۇرۇقلۇق نىسبىتىنى ئاشۇرىدۇ ۋە يۈن قۇرۇش پائالىيىتىدە ئىشلىتىلىدۇ. ئۇنىڭ خاسىيەتلىرىنىڭ كانونى، سۇغا قوشۇلغاندىن كېيىن كۆرۈنۈشچان بولۇشى ۋە پىچان قويۇشچانلىقى خاراكتېرلەنگەن، ئايلىرىغا قوشۇشچان ۋە تۇتۇش، سۇلغۇدەك لاس تاسافۇر قىلىش خاسىيىتىگە ئېرىشىش ئۈچۈن زۆرۈر.

methyl hydroxyethyl cellulose

In the ever-evolving world of construction and architecture, tile adhesion has become a critical component in ensuring lasting durability and aesthetic appeal in various installations. One key material that has gained significant popularity in recent years is Hydroxypropyl Methylcellulose (HPMC). This versatile polymer plays a pivotal role in formulating tile adhesives, which are essential for bonding tiles to various substrates, ensuring that installations not only look good but also stand the test of time.

4. Construction Industry In construction, HPMC is used in cement and gypsum-based products to enhance workability and water retention. It enables better adhesion and improves the performance of adhesives and mortar, making it indispensable in modern building applications.

Applications of HPMC

Another significant property of HPMC is its use as a controlled-release agent. Supplements formulated with HPMC can be designed to dissolve slowly in the digestive system, allowing for a gradual release of active ingredients. This controlled release can enhance the bioavailability of certain compounds, ensuring that nutrients are delivered efficiently to the body over an extended duration. Consequently, consumers may experience more sustained benefits from their supplements, which aligns with contemporary wellness trends that favor gradual and sustainable health improvements.

As the global economy continues to evolve, the trends surrounding HPMC prices are expected to fluctuate. The ongoing growth in the pharmaceutical sector, especially with the rising demand for generic medications and advanced drug delivery systems, is likely to sustain the demand for HPMC. Additionally, the construction industry's focus on sustainable materials and practices may propel the use of HPMC in greener building solutions.

HPMC dispersion is a fundamental component in numerous industries due to its versatile properties and adaptability to various applications. Understanding its preparation methods, characteristics, and uses allows manufacturers to harness its potential effectively. As the demand for sustainable and multifunctional materials continues to grow, HPMC dispersion will remain a vital ingredient in innovative product development across multiple sectors.

Furthermore, ongoing research and innovation are likely to lead to the development of new formulations that enhance the performance characteristics of RDP polymers. For instance, incorporating nanomaterials or additives could further improve strength, flexibility, and other essential properties.

I tillegg til farmasøytiske bruksområder er hypromellose blitt populært i kosmetikk- og personlig pleieprodukter. Det gir en glatt og behagelig tekstur, noe som gjør det til en vanlig ingrediens i kremer, lotioner og hårprodukter. Hypromellose kan også bidra til å stabilisere emulsjoner, noe som er viktig i mange kosmetiske formuleringer.

hypromellose hpmc

HPMC Viskositet En Nærmere Indsigt

Understanding HPMC Excipient A Key Component in Pharmaceutical Formulations

또한, HPMC Ltd는 품질 관리 시스템을 엄격히 적용하여 고객에게 최고의 제품을 제공하고 있습니다. 모든 생산 과정은 국제 기준에 맞춰 진행되며, 정기적인 품질 검사와 인증 절차를 통해 제품의 신뢰성을 보장하고 있습니다. 고객은 HPMC Ltd 제품을 사용함으로써 안심하고 높은 품질을 경험할 수 있습니다.

hpmc ltd

Construction and Building Materials

Kozmetik sektöründe de HPMC, krem, losyon ve şampon gibi ürünlerde sıkça yer almaktadır. Cilt bakım ürünlerinde, su bazlı formülasyonların viskozitesini artırarak, ürünlerin daha etkili bir şekilde uygulanmasını sağlar. Ayrıca, HPMC, yapay kalıp ve jelleşme özellikleri sayesinde, kullanıcılar için hoş bir kullanım deneyimi sunar.

In the pharmaceutical sector, HPMC serves as a binder, film-coating agent, and controlled-release agent in tablet formulations. Its non-toxic nature and favorable biocompatibility make it ideal for drug delivery systems, thus paving the way for innovative therapeutic solutions.

hpmc china

HPMC is synthesized by modifying cellulose, a natural polysaccharide found in the cell walls of plants. The modification process involves introducing hydroxypropyl and methyl groups into the cellulose structure. This modification significantly alters the solubility and functional properties of cellulose, allowing HPMC to dissolve in water and form viscous solutions, unlike its parent compound, which is insoluble in water.

- Pharmaceuticals for drug delivery systems, as a binder in tablets, and as a coating agent.