Links:

-

In conclusion, chain link security fences are a practical, cost-effective, and versatile option for protecting property and securing boundaries. Their strength, durability, visibility, and customization options make them a popular choice for many property owners. Whether used in commercial, industrial, or residential settings, chain link security fences provide peace of mind and reliable security for property owners. Plant cages are structures designed to protect plants from external factors such as wind, rain, and pests. They are typically made of metal or plastic and can be easily assembled and disassembled. These cages provide a safe haven for plants, allowing them to grow tall and strong without the fear of being uprooted or damaged. Step 5 Train the Plant The Transformational Power of Galvanized Steel Chicken Wire Another advantage of brick mesh walls is their thermal efficiency. The bricks act as a natural insulator, helping to regulate the temperature inside the building and reduce energy costs. This can be especially beneficial in colder climates where maintaining a consistent indoor temperature is essential. When designing a linear compression spring, several factors must be considered, including Tomato cages, typically made from wire mesh, are essential in supporting the sprawling vines as they grow. However, standard cages often fall short when faced with indeterminate tomato varieties that can reach heights of 6 feet or more. This is where the extra tall tomato cage steps in, offering a robust solution for gardeners dealing with towering tomato plants. Another advantage of plastic yard sign stakes is their affordability. Compared to other forms of outdoor advertising, such as billboards or banners, plastic yard sign stakes are relatively inexpensive. This makes them an attractive option for businesses on a budget. Even small businesses can afford to invest in plastic yard sign stakes to promote their products or services. In the complex landscape of corporate governance, the role of h stakeholders holds significant weight. This group, often overlooked or underestimated, comprises individuals or entities that have a vested interest in a company's performance and decision-making process. Their influence extends beyond the traditional shareholders, encompassing employees, customers, suppliers, the community, and even the environment. In the world of mechanical engineering, few components are as versatile and essential as adjustable coil springs. These springs, with their ability to be fine-tuned for varying levels of resistance, have found applications across a myriad of industries, from automotive to aerospace, and even in everyday household items. The installation process begins with marking the positions for the wall ties. Generally, these should be placed at regular intervals, usually every 300-600mm horizontally and 450-600mm vertically from the floor. Use a spirit level to ensure they're evenly spaced. Manufacturing industries heavily rely on iron wire for producing springs, wire ropes, mesh, and wire-based tools. Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire

Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire

Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire Wholesale distributors cater to the diverse needs of these sectors by offering a wide range of wire gauges and types, including galvanized, stainless steel, and high-carbon wire wholesale iron wire. Bed joint reinforcement typically involves the insertion of steel bars, wires, or mesh into the mortar beds between successive courses of masonry units. The reinforcement material, usually made from high-strength steel, is strategically placed to resist tension forces that could potentially damage the structure. This technique significantly improves the load-bearing capacity, shear resistance, and flexural strength of the masonry wall. In conclusion, small gridwall panels offer a versatile, durable, and cost-effective solution for organizing and displaying items in retail environments. Their flexibility in configuration, durability, ease of installation, and affordability make them a popular choice for businesses looking to create dynamic and attractive displays. Whether you are a retailer, exhibitor, or homeowner, small gridwall panels can help you showcase your items effectively and efficiently. Cookware and Kitchenware

wholesale iron wire. Bed joint reinforcement typically involves the insertion of steel bars, wires, or mesh into the mortar beds between successive courses of masonry units. The reinforcement material, usually made from high-strength steel, is strategically placed to resist tension forces that could potentially damage the structure. This technique significantly improves the load-bearing capacity, shear resistance, and flexural strength of the masonry wall. In conclusion, small gridwall panels offer a versatile, durable, and cost-effective solution for organizing and displaying items in retail environments. Their flexibility in configuration, durability, ease of installation, and affordability make them a popular choice for businesses looking to create dynamic and attractive displays. Whether you are a retailer, exhibitor, or homeowner, small gridwall panels can help you showcase your items effectively and efficiently. Cookware and Kitchenware

Masonry Ties: Critical for Secure and Durable Walls

Moreover, these panels offer excellent ventilation and light diffusion, making them perfect for use in environments where air circulation and natural light are crucial. In commercial buildings, they can enhance energy efficiency by facilitating the flow of air conditioning and lighting systems. They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management square metal grid panel.

square metal grid panel. Masonry ties, including wall ties and brick veneer anchors, are essential components in the construction of stable and durable masonry structures. Each type of tie serves a specific purpose, and their proper use is critical for maintaining structural integrity and preventing damage. By understanding the various types of masonry ties and their applications, construction professionals can ensure the success and longevity of their projects.

Despite their simple appearance, brick ties are engineered to be incredibly strong under tension forces. Their strength is calculated based on the size of the wall and the expected loads it will carry. This ensures that the ties can handle the weight of the bricks and any additional stresses caused by wind pressure, seismic activity, or other environmental factors. A linear compression spring is a helical spring that undergoes compression when subjected to an external force. The spring's coils are arranged in a spiral pattern, with each coil touching its neighbors. As the spring is compressed, the coils come closer together, storing potential energy. When the force is removed, the spring expands back to its original shape, releasing the stored energy. One of the primary advantages of PVC coated iron wire is its corrosion resistance. Since iron is prone to rusting when exposed to moisture and oxygen, the PVC coating acts as a protective barrier, preventing rust from forming. This makes the wire suitable for use in harsh environments where exposure to moisture and corrosive substances is common, such as construction sites, marine environments, and agricultural settings. Furthermore, the butterfly cavity wall ties contribute to the thermal efficiency of the building. By creating an air gap between the inner and outer walls, they facilitate insulation, reducing heat loss and improving energy performance. This is particularly important in modern construction where sustainability and energy efficiency are paramount. Tomato stands are not merely a commercial venture; they are a celebration of seasonal bounty, a reflection of regional diversity, and a testament to the resilience of human spirit. They embody the spirit of community, where people come together to appreciate the simple pleasures of life, the taste of freshly harvested tomatoes being one of them. 2. Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame

Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame thick floral wire. This will provide structure and support as you fill in the gaps with flowers and foliage. One of the key advantages of using concrete mesh lies in its ability to enhance the tensile strength of concrete. While concrete is inherently strong in compression, it is relatively weak in tension. By incorporating a mesh of steel wires, which has excellent tensile properties, the overall performance of the concrete is significantly improved. This is particularly crucial in structures that are subjected to dynamic loads, such as bridges, highways, and high-rise buildings.

thick floral wire. This will provide structure and support as you fill in the gaps with flowers and foliage. One of the key advantages of using concrete mesh lies in its ability to enhance the tensile strength of concrete. While concrete is inherently strong in compression, it is relatively weak in tension. By incorporating a mesh of steel wires, which has excellent tensile properties, the overall performance of the concrete is significantly improved. This is particularly crucial in structures that are subjected to dynamic loads, such as bridges, highways, and high-rise buildings. Masonry Wall Ties and Anchors: Ensuring Structural Integrity

Masonry joint reinforcement is designed to enhance the durability and longevity of masonry walls by preventing cracks and improving load distribution. This reinforcement, placed in the horizontal mortar joints of both brick and block walls, adds significant tensile strength to the structure. Available in various forms such as ladder and truss designs, masonry joint reinforcement can be tailored to specific structural requirements. The reinforcement helps control differential movement between the masonry units and the foundation, reducing the likelihood of vertical cracks. By integrating masonry joint reinforcement into the construction process, builders can ensure that the finished structure is more resistant to environmental stresses and long-term wear and tear.

Despite its numerous advantages, it's worth noting that solid galvanized wire may not be the perfect solution for every application. Factors like the severity of the corrosive environment, the required flexibility, and the specific load-bearing needs must be considered before selecting this material.Galvanized iron wire is not only a staple in the construction industry but also plays a crucial role in agricultural practices. The wire's durability, strength, and resistance to rust make it an excellent choice for various farming applications. Its versatility ensures that it can be used in multiple aspects of farming, contributing significantly to crop management and production efficiency.

Black chain mesh fencing is also highly customizable. With options for different gauges of wire, heights, and coatings, property owners can choose the specifications that best suit their needs. Additionally, black chain link fencing can be easily accessorized with privacy slats, barbed wire, or gates to further enhance its security and functionality.

In conclusion, the 42% tomato cage is a testament to the power of innovation and simplicity in solving complex problems. Its design offers farmers a practical solution that not only improves the quality and quantity of their harvest but also promotes sustainable farming practices. As we move towards a future where sustainability and efficiency are paramount, the 42% tomato cage serves as a beacon of hope for agricultural advancements. In the realm of construction engineering, one component that often goes unnoticed but plays a pivotal role is the 250mm brick tie. This seemingly insignificant element is an essential part of cavity wall construction, ensuring stability, durability, and safety in building structures. Firstly, we have the woven wire fence, also known as a 'welded wire' or 'field fence.' This type is made by weaving steel wires together, creating a strong and durable barrier. It's popular for its ability to keep animals contained while allowing visibility through the fence. The spacing between wires varies, with smaller gaps suitable for containing smaller animals like sheep or goats, while larger gaps work well for larger livestock like cattle. Businesses too have harnessed the power of yard sign stands In addition to these common types of cattle fences, there are also specialized options available for specific purposes. For example, high-tensile wire fences are designed to withstand the pressure exerted by cattle and are ideal for containing large herds. Mesh wire fences, on the other hand, provide a solid barrier that prevents cattle from escaping. In the context of a 2-inch compression spring, its relatively larger size makes it suitable for applications requiring higher force or more substantial deflection The Significance of Horizontal Joint Reinforcement in Masonry Construction

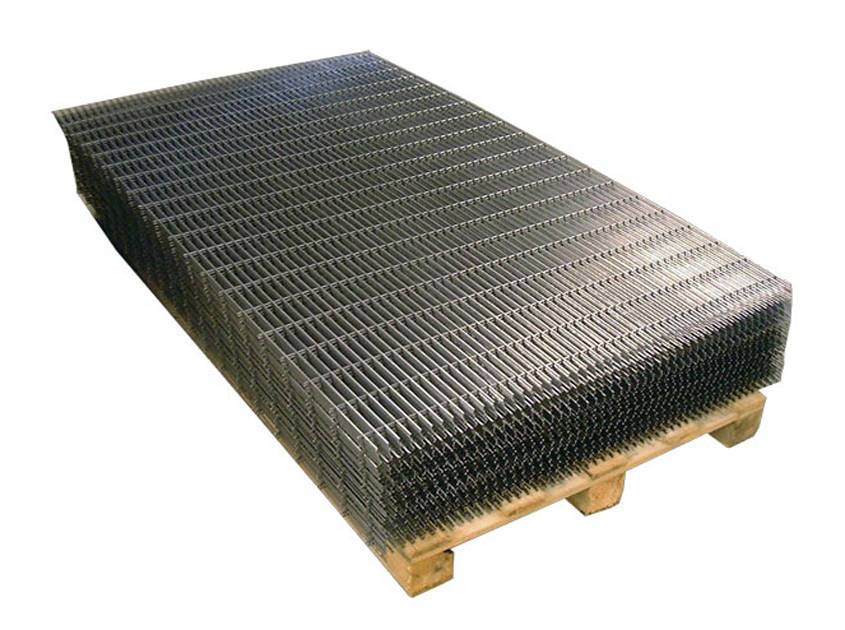

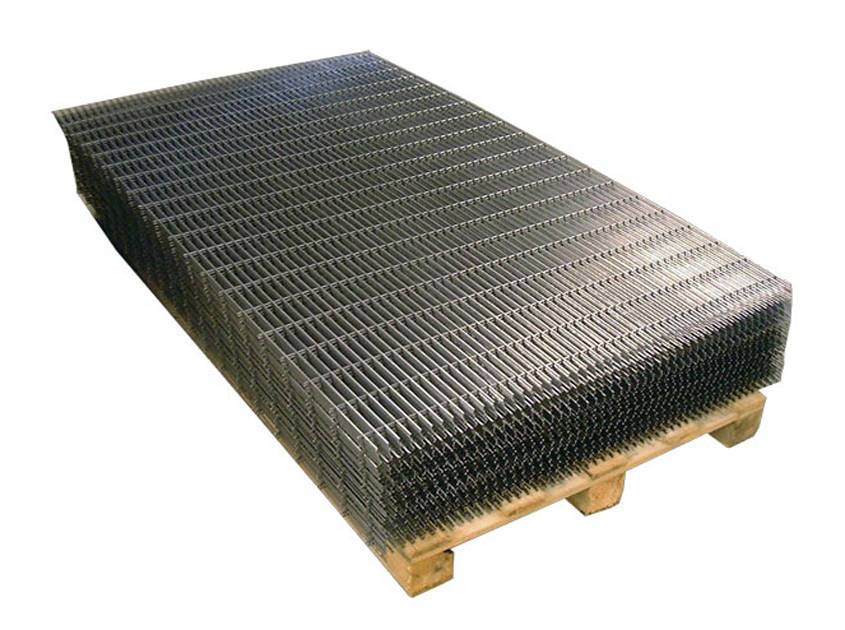

16 Gauge Dark Annealed Wire

In conclusion, horizontal sign holders are a powerful tool for businesses looking to increase their visibility and attract new customers. Their versatility, portability, and ease of use make them an ideal choice for a wide range of applications. By investing in high-quality horizontal sign holders, businesses can effectively communicate their message and stand out in a crowded marketplace. Overall, hot-dipped galvanized iron wire is a versatile and useful material that has a wide range of applications. Whether you're looking to build a fence, reinforce a structure, or create a decorative piece, this type of wire is an excellent choice. Its durability, strength, and resistance to rust and corrosion make it a reliable and long-lasting option for any project. In seismic zones, masonry tie-backs become even more critical. They help resist the lateral forces generated during earthquakes, mitigating potential damage and enhancing the seismic resilience of the structure. Moreover, in retrofitting projects, tie-backs are often employed to reinforce existing masonry walls, upgrading their safety and durability. Weldmesh suppliers play a crucial role in providing high-quality materials to construction companies, contractors, and DIY enthusiasts alike. By sourcing weldmesh from reputable suppliers, you can ensure that your project will be built on a strong foundation that will stand the test of time

weldmesh suppliers. Installation of a 47% 20-inch field fence requires careful planning and execution

The hexagonal tomato cage is a game-changer in the world of gardening. Its innovative design, durability, versatility, ease of use, cleanliness, and space-saving capabilities make it a must-have for any gardener. So why wait? Upgrade your gardening game today with the hexagonal tomato cage and enjoy bountiful harvests all season long.

The hexagonal tomato cage is a game-changer in the world of gardening. Its innovative design, durability, versatility, ease of use, cleanliness, and space-saving capabilities make it a must-have for any gardener. So why wait? Upgrade your gardening game today with the hexagonal tomato cage and enjoy bountiful harvests all season long. One of the key advantages of galvanized wire fence is its durability. The zinc coating acts as a sacrificial layer, corroding before the base metal, ensuring the fence remains intact even in harsh weather conditions. This makes it ideal for outdoor use where exposure to the elements is inevitable. It can withstand extreme temperatures, heavy rainfall, and even salty coastal environments, maintaining its structural integrity over time. In conclusion, joint reinforcement in masonry is more than just an add-on; it is a critical element that transforms a mere collection of individual units into a sturdy, resilient structure. It safeguards against structural failure, enhances the lifespan of buildings, and provides peace of mind to both builders and occupants. With advancements in materials science and construction techniques, the role of joint reinforcement in masonry is set to become even more crucial in the future, contributing to safer, more sustainable, and structurally sound edifices.

Black annealed wire is an essential material in the construction industry, primarily used for tying rebar (reinforcing bars) to ensure the stability and consistency of structures. This process is critical in creating reinforced concrete, which is a fundamental component of modern construction. The wire’s flexibility allows it to be easily wrapped around rebar, holding it securely in place. This not only ensures that the rebar remains in the correct position during the pouring and curing of concrete but also helps in maintaining the overall integrity of the structure.