Links:

-

Poultry netting, also known as chicken wire or poultry fencing, is a versatile and essential tool for those raising chickens or other poultry on their property. It is a lightweight yet durable mesh wire that is typically made from galvanized steel or plastic. Poultry netting is designed to keep poultry confined to a certain area while also offering protection from predators. When working with gold coloured craft wire, it is important to use the appropriate tools and techniques

gold coloured craft wire. A pair of round-nose pliers and wire cutters will be essential for cutting and shaping the wire, while a bench block or steel bench pin can provide a stable surface for bending and shaping the wire. It is also important to keep the wire clean and free of oils and dirt, as these can affect the wire's color and durability. Secondly, half-inch wire mesh offers excellent visibility while maintaining privacy. The small openings in the mesh allow light to pass through while obstructing direct views of the interior. This feature makes it perfect for use in residential and commercial settings where natural light is desired but privacy is a concern. For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside

gold coloured craft wire. A pair of round-nose pliers and wire cutters will be essential for cutting and shaping the wire, while a bench block or steel bench pin can provide a stable surface for bending and shaping the wire. It is also important to keep the wire clean and free of oils and dirt, as these can affect the wire's color and durability. Secondly, half-inch wire mesh offers excellent visibility while maintaining privacy. The small openings in the mesh allow light to pass through while obstructing direct views of the interior. This feature makes it perfect for use in residential and commercial settings where natural light is desired but privacy is a concern. For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside

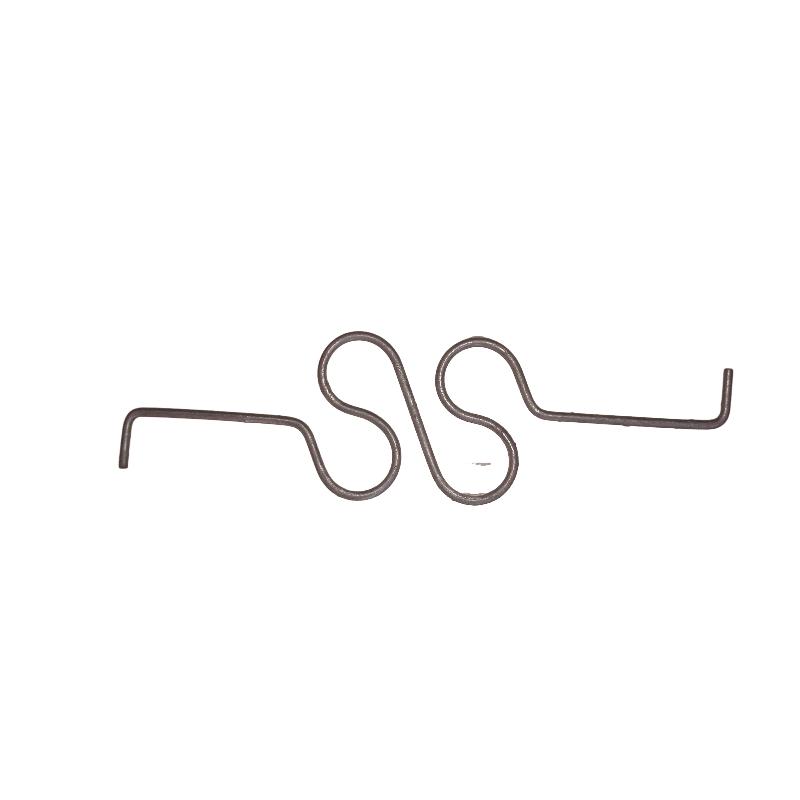

For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside For instance, it can be used as a window covering to let sunlight in while preventing outsiders from peering inside half inch wire mesh. Similarly, in office buildings, half-inch wire mesh can be installed on balconies or terraces to create a secure yet open environment for employees to enjoy their breaks. 3 Now, let's decipher the numerical part of our topic, 1 8 extension spring. In this context, 1 8 does not refer to a specific dimension or property but is likely an encoded or formatted reference. In web URLs or programming languages, often represents a space. Therefore, 1 8 could potentially be a placeholder for 1 8 or 1-8, possibly indicating the size or rating of the spring, such as the number of coils or the load capacity. Navigating the World of Wire Mesh Catalogues

half inch wire mesh. Similarly, in office buildings, half-inch wire mesh can be installed on balconies or terraces to create a secure yet open environment for employees to enjoy their breaks. 3 Now, let's decipher the numerical part of our topic, 1 8 extension spring. In this context, 1 8 does not refer to a specific dimension or property but is likely an encoded or formatted reference. In web URLs or programming languages, often represents a space. Therefore, 1 8 could potentially be a placeholder for 1 8 or 1-8, possibly indicating the size or rating of the spring, such as the number of coils or the load capacity. Navigating the World of Wire Mesh Catalogues In summary, understanding the different gauges of galvanized wire is critical to choosing the type that suits your needs. Whether you need the strength of 8 gauge galvanized wire or the flexibility of 14 gauge galvanized wire, there is a galvanized wire gauge to suit every application.

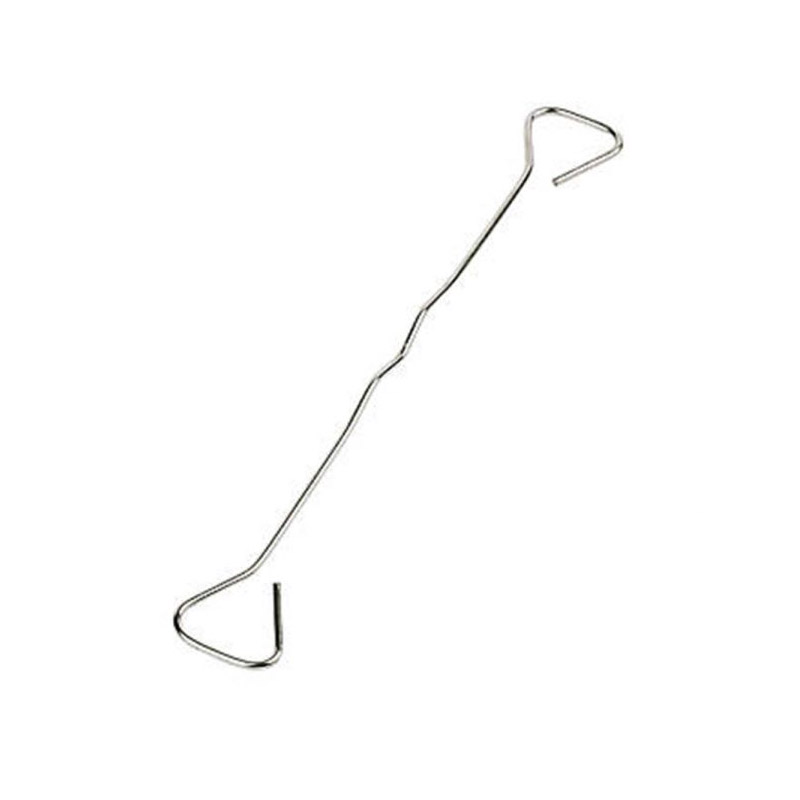

Masonry joint reinforcement is an essential aspect of construction engineering, particularly in the design and building of load-bearing structures. It refers to the process of reinforcing the joints between masonry units, such as bricks or blocks, to enhance their strength, stability, and overall durability. This practice has been widely adopted due to its significant role in improving the structural integrity of masonry constructions. In conclusion, chicken wire for sale is a versatile and practical material that can be used in a variety of applications. From keeping poultry safe and secure to creating garden fences and DIY projects, chicken wire is a cost-effective and reliable solution for anyone in need of a sturdy and durable wire mesh. So whether you are a farmer, a gardener, or a craft enthusiast, consider adding chicken wire to your arsenal of supplies for your next project. Finally, finishing touches such as applying rust-inhibiting lubricant to the fasteners and trimming excess mesh complete the transformation. Stand back and admire the handiwork; a well-replaced chain link fence not only serves its protective purpose but can also be a sight to behold. **The Grid SystemAnother crucial accessory is the reinforcement system, including steel bars, meshes, and ties. These reinforcements provide additional strength to the concrete, resisting tension forces and preventing cracks. They are strategically placed within the formwork to reinforce the concrete's structural integrity. Brick ties are usually made from materials such as galvanized steel, copper, or plastic, designed to withstand various weather conditions and resist corrosion. They are installed horizontally within the mortar joints of the brickwork, connecting each course of bricks to the stud wall behind. Their design varies, from simple wire ties to more complex anchor systems, but their function remains constant - to transfer loads from the brick skin to the wall cavity.

In addition to their adjustability, these springs also offer other advantages, such as improved control over the spring rate and the ability to customize the spring to meet specific requirements. This makes them a popular choice for engineers and designers who need a flexible and reliable solution for their spring needs.

The installation process of flat rib metal lath involves securing it to the underlying structure with fasteners, followed by the application of a scratch coat, a middle coat, and finally a finish coat

The Versatility and Durability of Galvanized Wire Fence

The Versatility and Durability of Galvanized Wire Fence Another advantage of using HD coil springs is their durability and longevity. Made from high-quality materials and designed to withstand heavy use, these coil springs are built to last. This means that vehicle owners can expect reliable performance and minimal maintenance requirements from their HD coil springs.

hd coil springs

Another popular option for cattle field fencing is electric fencing. Electric fencing works by delivering a mild electric shock to any animal that comes into contact with it. While this may sound harsh, the shock is not harmful and serves as a deterrent to keep cattle from pushing against the fence or attempting to escape. Electric fencing is also highly effective at keeping out predators such as coyotes and wolves

cattle field fence. while (buffer.getData() != null && !coder.isKeyFrame()) { The primary advantage of collapsible tomato cages is their portability. Unlike traditional, rigid cages that are bulky and difficult to move, collapsible cages can be easily folded down and stored when not in use. This makes them ideal for gardeners who have limited space or need to transport their plants frequently. Whether you're moving your plants to a new location or simply want to free up some space in your garden, collapsible cages make it easy to do so. Overall, reinforcement wire mesh panels play a crucial role in the construction industry, providing strength, stability, and versatility to a wide range of projects. Whether used for concrete reinforcement, fencing, or security barriers, these panels offer a cost-effective and durable solution for builders and contractors. With their ability to enhance the structural integrity of buildings and provide security for various applications, reinforcement wire mesh panels are an essential component in modern construction practices. Don't settle for inferior coil springs that can compromise the performance and safety of your vehicle. Upgrade today with our high-quality coil springs for sale and experience the difference for yourself. Contact us now to learn more or place your order. One of the primary advantages of the white wire grid is its adaptability. Whether it is used in a retail setting to hang products or in a home to display artwork and photographs, the grid offers a blank canvas for personalization. Its color, being white, seamlessly integrates with various color schemes without dominating the visual landscape. This allows the items displayed on the grid to take center stage, enhancing their visibility and importance within the space. Cavity ties are typically made of stainless steel or galvanized steel, which are highly durable and resistant to corrosion. They are designed to connect the two layers of a cavity wall together, ensuring that they remain securely in place and do not separate over time. Without cavity ties, the walls would be at risk of collapsing or becoming unstable, making them a vital component in the construction process. One of the main advantages of stainless steel plaster beads is their longevity. Unlike traditional plaster beads made from materials like galvanized steel or plastic, stainless steel beads are highly resistant to rust and corrosion. This means that they will not degrade over time, even in humid or wet environments. This makes them an ideal choice for exterior walls, bathrooms, and other spaces that are prone to moisture. 1. Heating Rate The rate at which the wire is heated can affect its microstructure and properties. Slow heating allows the wire to achieve a more uniform temperature distribution, resulting in better quality. 4. Energy storage Helical extension springs have a high energy storage capacity due to their helical shape, which allows them to store and release large amounts of energy. Today, Lovells continues to lead the way in the development of sustainable suspension solutions. They are committed to reducing their environmental impact by using recycled materials and implementing energy-efficient manufacturing processes. Lovells Coil Springs has come a long way since its humble beginnings over a century ago. Through continuous innovation and dedication to excellence, they have established themselves as a global leader in the field of suspension systems. As we look to the future, there is no doubt that Lovells will continue to push the boundaries of what is possible, shaping the future of automotive engineering. Not only is floral decorative wire beautiful and versatile, but it is also durable and long-lasting. Once you have created your masterpiece, you can enjoy it for years to come without worrying about it losing its shape or color. This makes floral wire a great investment for anyone looking to add a touch of beauty to their space. Consumer electronics often contain tension coil springs, hidden within intricate mechanisms such as retractable cables, watch springs, and even in the buttons we press daily When considering purchasing galvanized wire, it is essential to look for quality suppliers who offer a range of diameters, tensile strengths, and zinc coatings to suit specific needs. The wire's performance is directly linked to the quality of the galvanizing process, so choosing a reputable supplier is crucial. Installation of 5% 20-inch coil springs typically requires no special tools or modifications beyond basic hand tools and a floor jack. The ease of installation makes these springs an accessible upgrade for DIYers looking to enhance their vehicle's performance without breaking the bank or requiring extensive technical knowledge. The Panacea Tomato Cage A Green Thumb's Secret Weapon In addition to their energy storage capabilities, bidirectional torsion springs are also known for their reliability and durability. These springs are typically made from high-quality materials such as steel or stainless steel, which allows them to withstand the rigors of constant use without losing their ability to provide torque. One of the key benefits of a grid wall art display is its flexibility. The grid system allows you to easily switch out pieces of art, rearrange the layout, and experiment with different configurations to create a unique and personalized gallery wall. This makes it a great option for those who like to frequently change up their decor or for businesses looking to showcase a rotating collection of art. This growth can be attributed to several factors. Firstly, tomato cages promote better yield by allowing for better air circulation and sunlight exposure, thus reducing the chances of fungal diseases. Secondly, they make harvesting more convenient, saving time and labor costs. Lastly, with the global push towards sustainable agriculture, these cages are reusable, making them an eco-friendly option compared to single-use staking methods. Beyond commercial settings, metal grid panel stands find their way into homes as well. They can be used as room dividers, displaying plants, books, or decorative items. In the kitchen, they can hold pots, pans, and utensils, while in the garage, they can organize tools and equipment. Grid panels can also be used to display art and photos in a creative and stylish way. By attaching pictures and other decorative items to the grid, you can create a unique gallery wall that can be easily customized and changed as desired. This flexibility makes grid panels a great option for those who like to frequently update their décor. Outdoor metal grid panels, an architectural and engineering marvel, have become a staple in modern design and construction, offering a unique blend of functionality, aesthetics, and durability. These panels, often made from high-grade steel or aluminum, embody the perfect marriage between form and function, making them a popular choice for a wide range of outdoor applications. Adjustable compression springs are versatile and indispensable tools in the world of engineering and mechanics. Their ability to provide precise control over force makes them suitable for a wide range of applications. Whether it's in manufacturing, furniture design, medical equipment, the automotive industry, or electronics, these springs continue to play a vital role in enhancing the functionality and performance of various systems and devices. Finally, the location of your property can also affect the price of diamond mesh wire fence. If you live in an area with high demand for this type of fence, you may have to pay a premium price to get it installed. On the other hand, if you live in an area where there is less competition, you may be able to find a better deal on the same product. Secondly, the manufacturing process also affects the cost. For instance, mesh that undergoes a hot-dip galvanization process is pricier than that which receives a simple electro-galvanized coating. The former method provides a thicker layer of protection, thereby increasing the longevity and performance of the mesh. Furthermore, in the context of greenhouse construction, strong garden wire is often used to reinforce the frame, ensuring stability and longevity. It can also be employed to create DIY garden tools, like tomato stakes or plant supports, demonstrating its versatility and cost-effectiveness. While modern construction methods have evolved significantly, the use of brick ends ties remains a popular choice for many architects and builders

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique. The term galvanized refers to the process of applying a protective zinc coating to steel or iron to prevent rusting. In the case of wire fences, this process involves dipping the wire into a bath of molten zinc, creating a barrier that shields the underlying metal from the corrosive effects of moisture and air. This not only enhances the fence's longevity but also imparts an aesthetic appeal with its distinctive silver-gray finish. Not only are these cages functional, but they are also visually appealing. Their sleek, metallic finish can complement any garden design, adding a touch of modernity to the traditional gardening setup. When not in use, they can be conveniently stored flat, saving precious garden space. Installing a Tomato Cage A Step-by-Step Guide 3. Avoid performance bottlenecks Since hooks are executed during the Spring framework's lifecycle, it is crucial to avoid introducing performance bottlenecks. Be mindful of the order in which your hooks are executed and ensure that they do not unnecessarily delay the startup or execution of your application.

brick end ties. This is because they provide a cost-effective and reliable solution for joining bricks, while also adding an aesthetically pleasing touch to the final structure. The intricate patterns created by these ties can add depth and character to a building, making it truly unique. The term galvanized refers to the process of applying a protective zinc coating to steel or iron to prevent rusting. In the case of wire fences, this process involves dipping the wire into a bath of molten zinc, creating a barrier that shields the underlying metal from the corrosive effects of moisture and air. This not only enhances the fence's longevity but also imparts an aesthetic appeal with its distinctive silver-gray finish. Not only are these cages functional, but they are also visually appealing. Their sleek, metallic finish can complement any garden design, adding a touch of modernity to the traditional gardening setup. When not in use, they can be conveniently stored flat, saving precious garden space. Installing a Tomato Cage A Step-by-Step Guide 3. Avoid performance bottlenecks Since hooks are executed during the Spring framework's lifecycle, it is crucial to avoid introducing performance bottlenecks. Be mindful of the order in which your hooks are executed and ensure that they do not unnecessarily delay the startup or execution of your application.