Links:

Properties of HEC

What is Redispersible Latex Powder?

In conclusion, cement bonding additives play a crucial role in modern construction, contributing to stronger, more durable, and more efficient building practices. As the industry continues to evolve, these additives will remain vital in optimizing cement’s performance, ensuring that structures can endure the test of time and meet the demands of architects and builders alike. As sustainability becomes a more pressing concern, the development of eco-friendly bonding additives will also help shape the future landscape of construction, creating structures that are not only robust but also kinder to the planet.

What is HPMC?

4. Industrial Grade HPMC is employed in construction materials, especially in tile adhesives, paints, and coatings. Here, HPMC enhances workability, improves adhesion, and slows the drying process, allowing for better application and finish of construction products.

hpmc grades and uses

The Role of HPMC Manufacturers in Modern Industries

What is HPMC?

1. Improved Workability One of the most significant advantages of adding HPMC to gypsum plaster is enhanced workability. The polymer increases the viscosity of the plaster mix, leading to better consistency and smoother application. This allows contractors to achieve more uniform surfaces with fewer finishing issues, reducing labor time and improving overall project efficiency.

What is HPMC?

In addition, having a dedicated HPM contact number simplifies the process of resolving issues. Customers can quickly explain their problems and receive immediate guidance or solutions, reducing the frustration that often accompanies dealing with product-related issues. This commitment to excellent customer service is not only beneficial for the customers but also invaluable for HPM in building its reputation and brand loyalty.

Hair care products often capitalize on HEC’s film-forming abilities. It offers a protective barrier that can enhance shine and manageability in hair, allowing for a smoother application of styling products. Moreover, its non-toxicity and mildness make it an ideal choice for formulations aimed at sensitive skin or hair types.

HPMC is also non-ionic, which minimizes interactions with other charged substances in formulations. This property is particularly beneficial in the pharmaceutical industry, where HPMC is used as an excipient in tablets and gel formulations, providing controlled release of active ingredients. Furthermore, HPMC’s thermal stability and resistance to microbial growth enhance its usability in various settings.

Understanding HPMC and Its Role as an Excipient in Pharmaceuticals

In recent years, sustainable construction practices have gained significant traction, and HPMC aligns well with these initiatives. As a plant-based product, HPMC is biodegradable and derived from renewable resources. Its incorporation into construction materials can help reduce the environmental footprint of building projects while maintaining high performance.

- Quality Assurance Look for suppliers that adhere to international quality standards, ensuring that the HPMC produced is pure and effective for its intended use.

Hydroxypropyl Methyl Cellulose A Key Ingredient from China

In construction, HEC is utilized as a thickening and water-retention agent in cement and plaster formulations. Its inclusion in these materials helps to improve workability, allowing for easier application and reducing the risk of cracks and shrinkage. Furthermore, HEC can enhance the bonding strength of various materials, contributing to the overall durability of construction projects.

In the pharmaceutical industry, hydroxyethyl cellulose serves a crucial role as a binding agent in tablet formulations and a thickening agent in topical creams and ointments. Due to its ability to modify viscosity, it ensures the even distribution of active ingredients in these formulations, enhancing their effectiveness. Furthermore, HEC is also utilized in controlled-release drug delivery systems, where it aids in regulating the release rate of drugs from the dosage form, thereby improving therapeutic outcomes.

what is hydroxyethyl cellulose

Conclusion

Conclusion

Understanding Different Grades of HPMC An Overview

Redispersible powders are also widely used in the formulation of paints and coatings. They act as film-forming agents, which help to improve the overall durability and performance of these products. The incorporation of redispersible powder allows for better adhesion to surfaces, enhanced scratch resistance, and improved resistance to moisture and chemicals.

Redispersible Polymer Powder (RDP) has become an indispensable component in various construction and building materials due to its unique properties and versatility. As a dry powder, RDP is derived from emulsions of synthetic polymers that are spray-dried to form a powder. Once mixed with water, it re-disperses to recreate the original emulsion, providing a host of benefits that significantly enhance the performance of construction applications.

Understanding HPMC

In conclusion, HPMC 4000 CPS is a multifaceted polymer that plays a crucial role in various industries, from pharmaceuticals to food and cosmetics. Its unique properties, such as viscosity, emulsification, and stabilizing characteristics, make it an invaluable component in modern product formulations. As industries continue to evolve, HPMC 4000 CPS is likely to remain a key player, demanding innovation and sustainable practices for future applications.

One of the most significant benefits of using cement bonding additives is the enhancement of the overall strength of the cement matrix. By providing better interfacial bonding, these additives reduce the likelihood of delamination or separation of layers. For instance, in applications such as plastering or applying new concrete overlays, the presence of bonding agents ensures that the new layer adheres effectively to the substrate. This is especially crucial in repair and renovation projects where the integrity of existing structures must be maintained.

cement bonding additive

The viscosity grade of HPMC significantly influences its application.

3. Flexibility and Crack Resistance Many mortar adhesive additives provide a degree of flexibility to the hardened mortar, allowing it to accommodate slight movements in the substrate without cracking. This flexibility is crucial in areas that experience temperature fluctuations or structural shifts.

Conclusion The Future of RDP Powder in Construction

5. Interface mortar:

Key Drivers of Market Growth

Uses of Hypromellose

Diverse Applications Across Industries

Dispersible polymer powders exhibit several defining characteristics that make them valuable in formulating products. Firstly, they possess excellent water solubility, allowing them to quickly and easily integrate into aqueous systems. This solubility contributes to improved workability and processing characteristics, making them ideal for use in construction materials like cement-based products. Additionally, they often enhance the mechanical properties of the final product, such as flexibility, durability, and adhesion.

1. Pharmaceutical Industry HPMC plays a crucial role in the pharmaceutical sector, where it is employed as a binder in tablet formulations, a stabilizer in suspensions, and a controlled-release agent. Its ability to form gels and modify drug release rates allows for enhanced bioavailability and therapeutic efficacy.

Environmental considerations are also at the forefront of Ashland’s developmental strategies. The company is dedicated to sustainability and reducing its ecological footprint, implementing responsible sourcing practices for raw materials used in HEC production. As consumer demands shift towards more sustainable and eco-friendly products, Ashland is well-positioned to lead the charge in creating HEC solutions that align with these values.

2. Enhanced Flexibility Traditional mortars may be prone to cracking due to thermal expansion and contraction. Mortar bonding additives provide greater flexibility, allowing the mortar to withstand these movements without compromising the integrity of the bond.

Applications in Various Industries

Moreover, redispersible latex powders enhance the flexibility of plaster and render formulations, enabling them to withstand thermal expansion and contraction

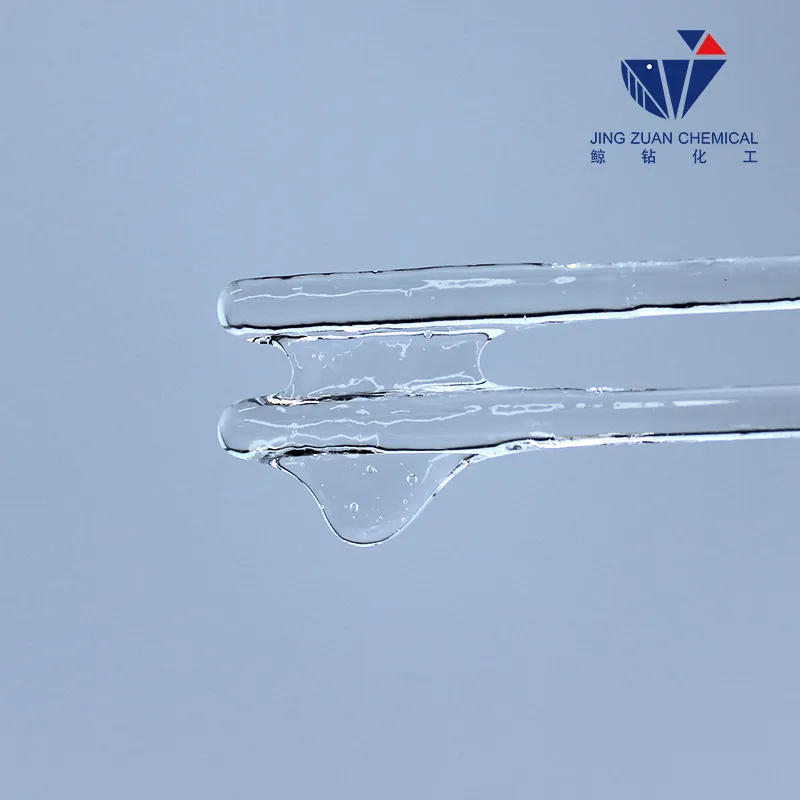

. This characteristic is particularly important in regions with fluctuating temperatures. Additionally, these powders are also beneficial in the formulation of self-leveling compounds, which require excellent flow characteristics and adhesion properties.redispersible latex powder

HPMC is a semi-synthetic polymer derived from cellulose, the most abundant organic polymer on Earth. It is created by chemically modifying cellulose to enhance its water solubility and functionality. The compound is known for its ability to form gels, provide thickening, and create emulsions. Due to its non-toxic and biodegradable nature, HPMC is widely accepted in various applications, including those that require strict regulatory compliance, such as in the pharmaceutical and food industries.

In the realm of personal care products, HEC serves as a versatile ingredient in formulations ranging from shampoos and conditioners to lotions and creams. Its thickening properties not only improve the texture of these products but also enhance their stability and performance. HEC's ability to form a protective film on the skin and hair helps in retaining moisture, providing added benefits such as hydration and shine. Its non-toxic and hypoallergenic nature makes it suitable for sensitive skin, further expanding its applicability in cosmetic formulations.

The pH of the solution can also influence the solubility of HEC. Typically, HEC exhibits good solubility in neutral to slightly alkaline environments. Extreme pH levels, whether acidic or alkaline, can lead to hydrolysis of the polymer backbone or side groups, thus affecting its solubility and functionality.

4. Regulatory Compliance HPMC is generally recognized as safe (GRAS) by regulatory authorities, making it a compliant choice for food and pharmaceutical applications. This aspect not only assures consumers of product safety but also helps brands build trust with their audience.

Methyl Hydroxyethyl Cellulose Suppliers in China An Overview

1. Measure the HPMC and Water Determine the total amount of HPMC needed for your formulation. A typical concentration ranges from 0.5% to 5% by weight, depending on the desired viscosity. Measure the appropriate amount of water and HPMC accurately.

how to dissolve hpmc in water

4. Neutralization After the etherification reaction, the mixture is neutralized to remove excess alkali, often with dilute acids. This step is crucial for stopping the reaction and isolating the HEC product.

In the world of construction, the integrity and longevity of structures are paramount. One of the essential components that influence these factors is the bonding quality of cement. This is where cement bonding additives come into play. These additives are chemical or mineral substances incorporated into cement mixtures to enhance performance, improve adhesion, and ensure durability in various applications.

In the construction sector, HPMC is utilized in mortar and plaster applications. It enhances the workability and adhesion properties of cement-based materials, ensuring better performance in construction projects. By improving water retention, HPMC allows for longer working times and reduces the risk of cracking, ultimately leading to more durable structures.

Benefits of HPMC in Gypsum Plaster

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic, water-soluble polymer derived from cellulose. It is widely used in various applications, from pharmaceuticals to food products, and most notably in the construction sector as a thickening agent and binder in tile adhesives and grouts. HPMC is produced through the reaction of cellulose with propylene oxide and methyl chloride, resulting in a versatile compound that enhances the performance of adhesive products.