Links:

3. Visible Damage During routine maintenance, mechanics can visually inspect the timing belt for signs of wear such as cracks, fraying, or missing teeth.

What is a V-Belt?

Benefits of Variable Belt Drives

The 84.5% Serpentine Belt

Conclusion

The primary function of a V-belt is to transmit power from one rotating shaft to another. When a motor turns a pulley connected to a V-belt, the belt transfers this motion to another pulley, often driving a connected machine, such as a fan, compressor, or conveyor. This design minimizes slippage, which is a common issue in flat belt systems. The wedging action of the V-belt into the pulley grooves allows for a tighter grip, which translates to better power transmission efficiency.

The ribbed V-belt is a crucial component in Hyundai vehicles, ensuring that various engine accessories function harmoniously. As an owner, being informed about this component’s significance, maintenance, and signs of wear will help ensure the longevity and performance of your vehicle. Regular inspections and adhering to recommended maintenance schedules can prevent unexpected breakdowns and keep your Hyundai running smoothly for years to come. Remember to consult with a trusted mechanic or dealership for any concerns regarding your vehicle’s ribbed V-belt, as they can provide valuable insights and service tailored specifically to your Hyundai model.

1. Efficiency With improved grip thanks to their ribbed design, 5pk belts ensure that components receive adequate power supply without excessive strain. This efficiency translates to better performance and longevity of the engine accessories.

In addition to the automotive industry, poly belts are extensively used in manufacturing and processing plants. For instance, conveyor systems that transport materials often rely on these belts for their durability and efficiency. The increased load-bearing capacity of a 7PK 2300 belt ensures that heavy materials can be moved without slippage or excessive wear, which is critical in maintaining operational efficiency.

poly belt 7pk 2300

4. Quiet Operation Flat drive belts produce less noise compared to other belt types. This characteristic is particularly important in environments where noise reduction is a priority, such as in office buildings or residential areas.

2. Versatility Sawtooth conveyor belts are highly versatile and can be used in various industries, including food processing, packaging, mining, and automotive. They can accommodate a wide range of products, from lightweight items to heavy machinery parts.

The Hyundai H100 is a versatile light commercial vehicle that has won the trust of many businesses and individuals alike. Built for reliability and performance, one of the critical components that ensure the smooth operation of the H100 is its timing belt. This article will provide an in-depth overview of the timing belt's role, maintenance, replacement intervals, and tips for owners.

4. Entertainment Interestingly, Belt PK is also prevalent in the entertainment industry, especially in amusement rides and machinery used in theaters. Here, the reliability of belts ensures smooth operation and safety for users.

Conclusion

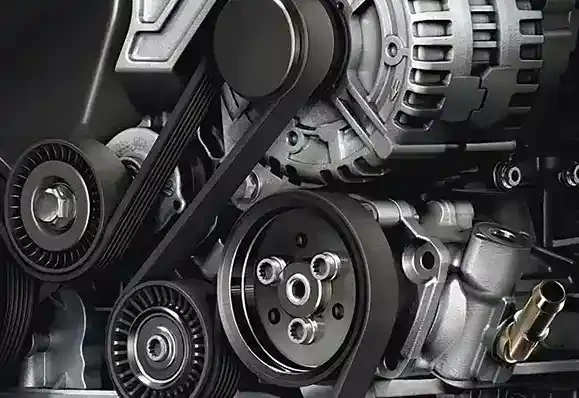

When it comes to automotive maintenance, the significance of every component cannot be overstated. Among these, fan belts, often referred to as serpentine belts, play a crucial role in a vehicle’s performance. In the automotive industry, the wholesale market for fan belts has emerged as a vital resource for both mechanics and car owners who are keen on maintaining their vehicles efficiently and cost-effectively.

Applications of 1.8 T Timing Belts

The engine is often considered the heart of a car, meticulously designed to convert fuel into motion. However, this complex system relies heavily on a less celebrated component known as the engine belt. In this article, we will explore the function, types, maintenance, and overall importance of the engine belt in vehicles.

Given the critical role that belts play in the overall manufacturing process, it is vital for businesses to evaluate their inventory needs and consider adopting a 10pk purchasing strategy. By doing so, organizations can enhance their productivity, minimize downtime, and ultimately drive greater profitability in an increasingly competitive marketplace. As technology advances and manufacturing processes evolve, the importance of high-quality, durable belts will only continue to grow, making them indispensable tools in the modern manufacturing toolkit.

Automotive parts can be classified broadly into several categories engine components, transmission systems, suspension and steering systems, braking systems, and electrical parts. Each category plays a vital role in how a vehicle operates and offers various features that enhance the driving experience.

The Composition and Characteristics of Flat Leather Machine Belts

There are several types of V-belts available, categorized primarily based on their construction and application. The most common types include

Applications

belt drive

Fan belts, often referred to as serpentine belts or drive belts, play a crucial role in the functioning of an automobile's engine. Despite their seemingly simple design, these components are integral to the overall performance and efficiency of a vehicle. As one of the unsung heroes of automotive engineering, fan belts warrant a closer look at their functionality and importance.

3. Consider Load and Speed Requirements Determine the operational load and speed of the machinery. Heavier loads may require belts with improved tensile strength and durability.

Consequences of Neglecting Timing Belt Maintenance

- Space Efficiency Their compact design allows for the reduction of space in engine compartments and machinery layouts.

In the dynamic world of fashion, trends come and go, but some styles—like the belt flat—have proven to be both timeless and versatile. The concept of the belt flat combines the practicality of a belt with the elegance of flat footwear, leading to a trend that caters not only to comfort but also to aesthetic appeal. This article explores the various dimensions of belt flats, from their history and design to their impact on contemporary fashion.

- Industrial Machinery Poly V belts are employed in numerous industrial machines, from conveyor systems to textile machinery. Their ability to handle varying loads and maintain power transmission efficiency is crucial in these settings.

Ribbed drive belts are vital components in modern machinery, offering enhanced efficiency, flexibility, and durability. Their unique design allows for multiple applications across various industries, making them indispensable in today's mechanical landscape. As technology continues to evolve, the development of ribbed drive belts will likely expand, further enhancing their performance and applicability. Understanding both their mechanical functions and maintenance requirements will ensure that they continue to provide reliable service for years to come.

Moreover, poly rib belts are typically made from durable materials such as EPDM (ethylene propylene diene monomer) rubber, which enhances their resistance to heat, oil, and ozone. This durability translates into longevity, making poly rib belts less prone to wear and tear and reducing the frequency of replacements.

In the world of fashion, few items carry the same aura of nostalgia and timeless appeal as vintage leather kidney belts. These unique accessories, often characterized by their distinctive silhouette and artisan craftsmanship, have found their way back into contemporary wardrobes, capturing the hearts of fashion enthusiasts and collectors alike.

- Industrial Machinery From conveyor systems to robotics, S5M timing belts are utilized in machinery that requires precise timing and positioning for optimal performance.

2. Flexibility and Adaptability The versatility of V-belts allows them to be used in various setups, whether it's in agricultural machinery, HVAC systems, or manufacturing equipment. They can operate in both horizontal and vertical layouts, providing manufacturers with design flexibility.

v-belts transmission 2150

5. Versatile Usage Back support belts are not limited to motorcycle riding; they can be beneficial in other activities that require prolonged sitting or physical exertion. This versatility makes them a valuable tool for anyone engaged in activities that strain the back.

Manufacturing Processes

Moreover, the PK belt has seen a surge in popularity among fashion influencers and celebrities. Social media platforms, particularly Instagram and TikTok, have played a significant role in showcasing how this accessory can enhance personal style. Influencers often demonstrate various ways to wear the PK belt, from cinching oversized shirts to adding definition to flowy dresses. This adaptability not only showcases the belt's functionality but also encourages creativity in fashion.

In recent years, vintage biker belts have surged in popularity far beyond the motorcycle community. Fashion enthusiasts and influencers have adopted these belts, pairing them with everything from casual outfits to high-fashion ensembles. The beauty of the vintage biker belt lies in its versatility.

Average Prices

If the owner’s manual is not available, you can opt for the second method measuring the existing belt. To do this, remove the old belt and measure its length and width using a tape measure. Be sure to measure the belt when it is straightened out, as this will give you the most accurate measurement. It is also advisable to note the belt's type, which can often be found printed on its underside.

Like any other commodity, the price of rubber wrapped banded V belts is subject to fluctuations in market demand and supply. During peak seasons when machinery use is at its highest, demand for V belts can surge, leading to an increase in prices. Conversely, during off-peak seasons, prices may drop as suppliers aim to offload inventory.

1. Increased Durability One of the main benefits of double timing belts is their enhanced durability. The dual structure distributes the workload more evenly, which can lead to a longer lifespan compared to single timing belts. This is particularly important in high-performance vehicles that experience greater stress on engine components.

When replacing the camshaft drive belt, it can be wise to replace other related components, such as the water pump and tensioner, to prevent future issues and extend the life of the new belt. Additionally, it is important to ensure that the new belt is correctly installed and tensioned to avoid the complications that arise from incorrect synchronization.

3. Longevity Belts are designed to withstand wear and tear over long periods, leading to a greater lifespan compared to chains. With proper usage, a belt can last for a significant number of miles, reducing the need for replacements and making them economically advantageous in the long run.

belt driven motorbike

Types of V-Belts

Advantages of V-Belt Clutches

Conclusion

2. Pain Relief For riders suffering from existing back pain, wearing a support belt can provide immediate relief. The compression offered by these belts supports the lower back muscles, lessening discomfort and allowing for longer rides without pain.

2. Pitch (5 mm) The 5M refers to the pitch of the belt, which is the distance between the centers of two adjacent teeth. A pitch of 5 mm is designed for moderate power transmission and offers a balance between flexibility and strength. It is ideal for applications that require compact design without sacrificing performance.

What is a PK Belt?

What is the V-Face Lift Massager Belt?