Links:

Another advantage is their ease of installation and replacement. Many drive belts can be replaced quickly, minimizing downtime for equipment. Regular inspection and maintenance can help identify wear or damage early, ensuring that the belts continue to operate efficiently.

When it comes to car maintenance, timing belts play a crucial role in ensuring the smooth operation of your engine. As a critical component, timing belts synchronize the rotation of the crankshaft and camshaft, allowing the engine's valves to open and close at the proper intervals. This intricate timing is essential for optimal engine performance. However, one common question among vehicle owners is what influences the price of timing belts?

Understanding the Importance of Car Toothed Belts

Without a functional timing belt, an engine can experience catastrophic failure. If a timing belt breaks or slips, it can lead to severe engine damage, such as bent valves, damaged pistons, and even a complete engine overhaul. In non-interference engines, the damage may be minimal, but in interference engines, where the valves and pistons occupy the same space, the consequences can be dire. Therefore, regular maintenance and timely replacement of the timing belt are paramount to avoid costly repairs.

Importance of the Timing Belt

Factors Influencing Engine Belt Costs

The automotive industry is a vast and intricate ecosystem, continually evolving with advancements in technology, consumer preferences, and market demands. Among the critical components that keep this industry thriving is the wholesale automotive parts sector. This market segment plays a significant role in the overall success of automotive businesses, from repair shops to large-scale vehicle manufacturers. Understanding the intricacies of the wholesale automotive parts market can provide valuable insights into its growing significance.

V posledních letech se automatické pásy staly klíčovým prvkem v mnoha odvětvích, od výroby po logistiku a dokonce i v oblasti zábavy. Tyto systémy, které umožňují efektivní a automatizovanou manipulaci s materiály, představují revoluci v způsobu, jakým se zboží přesouvá v průmyslových a komerčních prostředích. V tomto článku se podíváme na vývoj automatických pásů, jejich výhody a aplikace, které mají zásadní dopad na moderní průmysl.

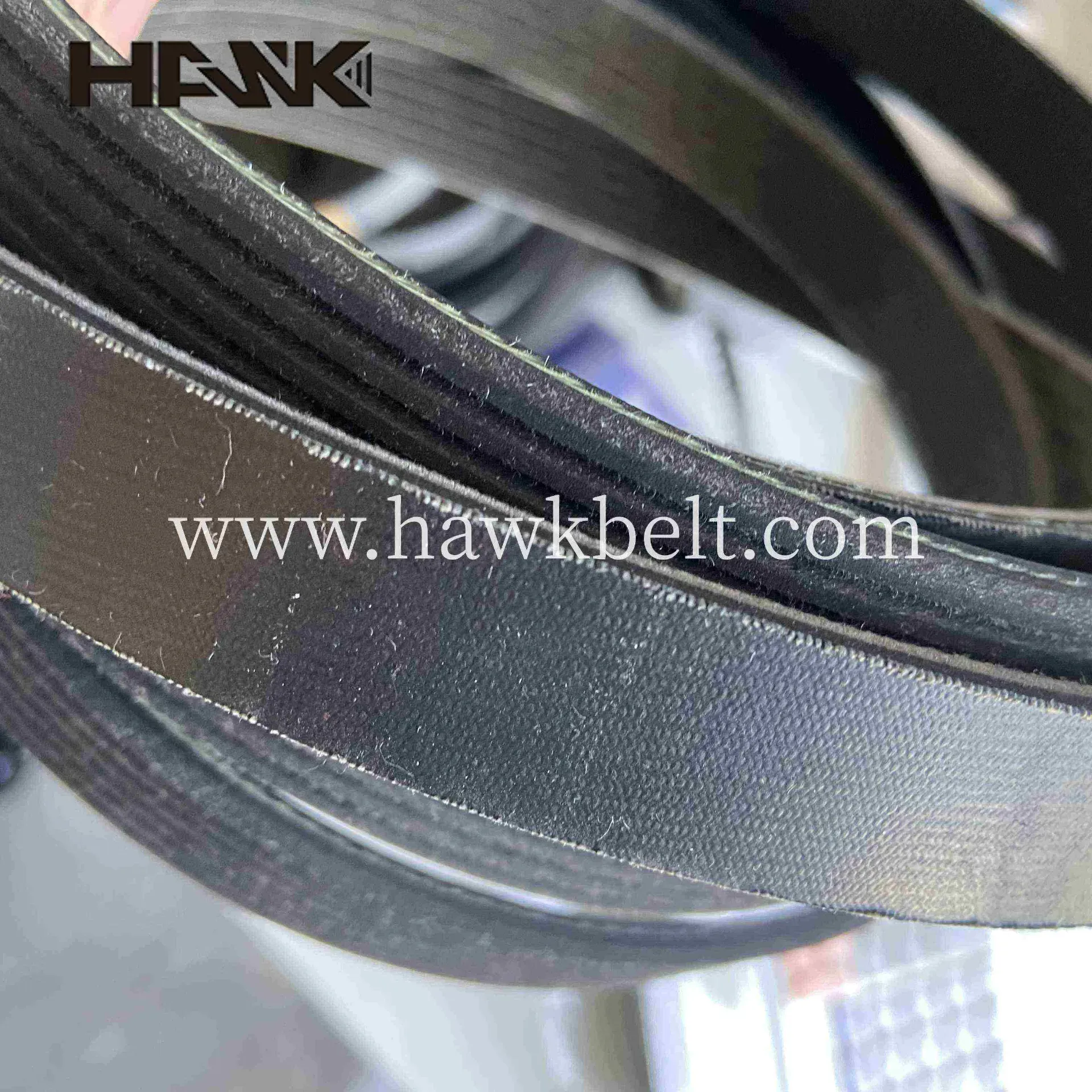

2. Compact Design Due to the simultaneous operation of multiple ribs, Poly-V TB2 belts require less space than traditional V-belts. This design is advantageous in compact machinery where space is a premium. Fewer pulleys and belt runs are required, allowing for lighter and more straightforward machinery configurations.

Timing belts don’t last indefinitely. Most manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, depending on the vehicle model and driving conditions. Regular inspection and maintenance are crucial because a worn or damaged timing belt can lead to significant engine problems. If the belt breaks while driving, it can cause severe engine damage, particularly in interference engines, where pistons and valves occupy the same space.

Considerations

Like any component, belts show signs of wear and tear over time. It is crucial for operators to routinely inspect belts for cracks, fraying, or loss of tension. Indicators that a 207PK belt may need replacement include slipping during operation, unusual noises, or visible damage. Regular maintenance, including timely replacement of worn-out belts, is key to ensuring the efficiency and safety of machinery.

Limitations of Belt Drives

3. Cost-Effectiveness Compared to other power transmission systems, such as gear systems, V-belts and pulleys are generally more cost-effective, both in terms of initial investment and maintenance.

In the intricate machinery of an automobile, every component plays a crucial role in ensuring optimal performance and efficiency. Among these components, the timing belt stands out as one of the most essential parts in an internal combustion engine. Although often overlooked during routine maintenance, understanding the function and significance of the timing belt is vital for every car owner.

3. Budget While it's tempting to go for the cheapest option, consider the long-term value of investing in a quality belt. More expensive belts tend to last longer and require less maintenance.

Functional Applications

1. Material Quality

The Importance of Automatic Door Timing Belts Ensuring Efficiency and Safety

Conclusion

3. Additional Repairs When replacing a timing belt, many mechanics recommend replacing other components while the engine is apart, including the water pump and pulleys. This precaution can prevent potential failures and save on future repair costs. Bundling these services can further escalate the initial costs, bringing the total bill to $800 or more in some cases.

engine belt cost

- Agricultural Equipment Tractors and harvesters often rely on universal V-belts to drive equipment such as plows, mowers, and conveyor systems. The reliability of these belts ensures that agricultural operations remain efficient during critical planting and harvesting seasons.

Timing belts are looped bands made of flexible material, typically reinforced with fibers to enhance their strength. They are designed to synchronize the rotation of shafts, ensuring that various components within a machine operate in harmony. This synchronization is essential in numerous applications, such as automotive engines, conveyor systems, and industrial machines, where precise timing is crucial for optimal performance.

Applications of Synchroflex T2.5

.

Belts from this era often boasted designs that reflect the brands and motorcycle clubs of the time, showcasing logos and symbols that resonate with enthusiasts. The attention to detail and the quality of materials used in these belts highlight the pride of the craftspeople who created them, making each piece a wearable work of art.

The alternator belt cost is an important factor for vehicle owners, as it directly impacts the overall maintenance expense. Modern rubber ribbed belts are designed for durability and efficiency, ensuring long-lasting performance while minimizing replacement frequency. Investing in a high-quality new serpentine belt might initially seem costly, but it provides better value by reducing wear and tear on engine components and extending the life of the belt itself.

The integration of technology into automotive parts has had a profound impact on the industry. Intelligent systems, including sensors, cameras, and connectivity features, have given rise to advanced driver-assistance systems (ADAS). These technologies enhance safety through features such as adaptive cruise control, lane-keeping assistance, and automatic emergency braking.

Importance of Choosing the Right Belt

Toyota Hiace is a popular choice among vans, known for its durability, versatility, and spacious interior. Whether used for commercial purposes or as a family vehicle, the Hiace has gained a dedicated following worldwide. However, like any vehicle, regular maintenance is essential to ensure its longevity, and this often involves the need for spare parts. In this article, we will delve into the various aspects and importance of Toyota Hiace spare parts.

1. Regular Inspections Routine checks for signs of wear, fraying, or misalignment are essential. Belts should be examined visually for any cracks or material degradation.

- Regular Inspections Regularly inspect the PK belt for signs of wear, especially during routine maintenance checks.

What Does PK % Blet Mean?

In the realm of mechanical engineering, the efficient transfer of power between different components is critical. One of the essential tools in this regard is the V-belt sheave, commonly referred to as a pulley. This component plays a pivotal role in various machinery and systems, facilitating the movement of power through the use of belts, most notably V-belts.

3. Cogged V-Belts Featuring notches along the length, these belts reduce bending resistance, making them ideal for applications requiring flexibility.

- Regular Inspections Periodically check the belt for signs of wear. Doing so can help you avoid unexpected breakdowns and expensive repairs.

A V-belt, as the name suggests, has a trapezoidal cross-section that resembles the letter V. This unique shape allows the belt to fit snugly into the pulley grooves, ensuring secure engagement and efficient power transmission. V-belts come in various sizes and materials, including rubber, polyester, and polyurethane, catering to different load capacities and operational environments.

Practical Accessories

The design usually includes a thickness that provides strength without compromising flexibility. Additionally, the length of the belt can be easily adjusted to accommodate different machinery configurations. This adjustability is particularly beneficial in applications where machinery may require periodic adjustments or maintenance.

1. Squeaking or Whining Noises Unusual noises emanating from the engine, especially when starting the vehicle or turning the steering wheel, can indicate a worn belt.

auto belt 4pk

Additionally, flat top belts are widely utilized in the logistics and material handling sectors. They facilitate the easy movement of packages in warehouses and distribution centers, enabling effective sorting and organization.

3. Cleanliness Keep the belt free from oil, dirt, and debris, which can significantly affect grip and performance. Oil contamination, in particular, can lead to slippage and overheating.

In conclusion, the 8PK belt is an essential component in modern machinery, providing enhanced power transmission, durability, and versatility. Its ability to operate under demanding conditions makes it a preferred choice in various industrial and automotive applications. By investing in high-quality 8PK belts and adhering to proper installation and maintenance practices, industries can achieve greater efficiency and reliability in their operations. As technology continues to evolve, the importance and usefulness of the 8PK belt are likely to expand even further, solidifying its role as a crucial element in engineering and industrial machinery advancements.

The LB7 engine, a highly regarded diesel powerplant, is known for its reliability and performance in various General Motors vehicles, especially the GMC and Chevrolet trucks. One critical component of this engine's functionality is the serpentine belt. This article will delve into the importance of the serpentine belt in the LB7 engine, maintenance tips, and signs indicating when it needs replacement.

Understanding Timing Belts

When compared to traditional materials, poly belting provides several advantages. Traditional rubber belts may fail under heavy loads or extreme conditions, leading to costly downtimes and maintenance issues. In contrast, the robust nature of polyurethane belting allows it to handle conditions that would quickly degrade rubber. Furthermore, polyurethane does not suffer from issues like cracking or splitting, ensuring a longer service life with less frequent replacements.

Like all mechanical components, serpentine belts wear out over time. Regular inspection is essential to catch any deterioration early. Common signs of a failing serpentine belt include

serpentine belt use

Looking ahead, the future of the V-belt market in Thailand appears promising. With ongoing infrastructure development and a strong emphasis on industrial growth, the demand for power transmission solutions will likely continue to rise. As businesses increasingly recognize the importance of efficiency and sustainability, the V-belt industry has a pivotal role to play in supporting Thailand's economic objectives.

4. Комфорт водіння Завдяки покращеній синхронізації роботи двигуна, автомобілі з автоматичним таймінгом демонструють плавнішу їзду та менше вібрацій. Це значно підвищує комфорт водіння, особливо на великих відстанях.

Understanding Fan Belt Size A Comprehensive Guide