Current location:

Links:

-

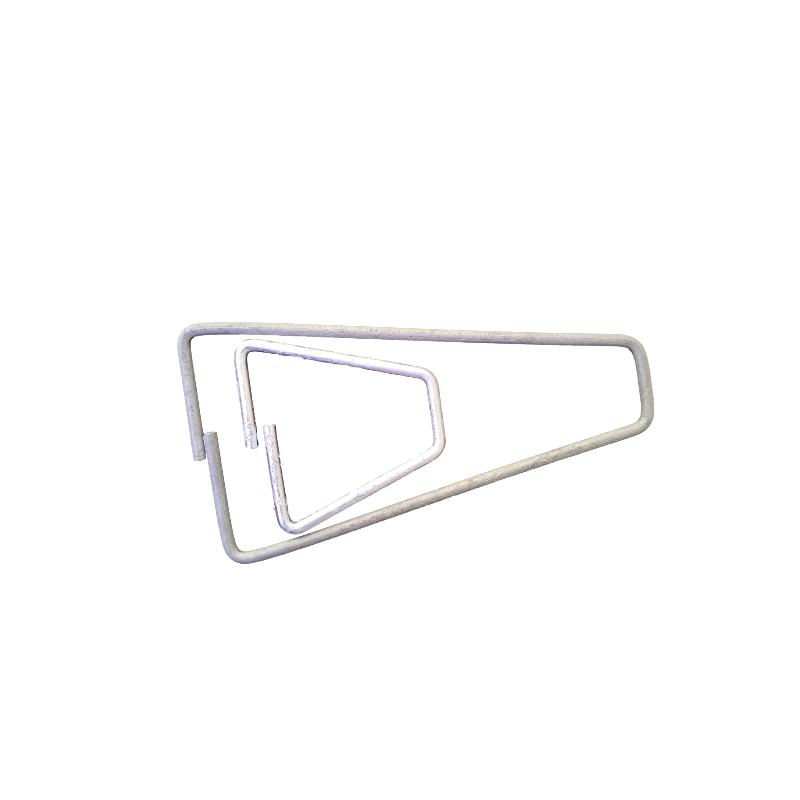

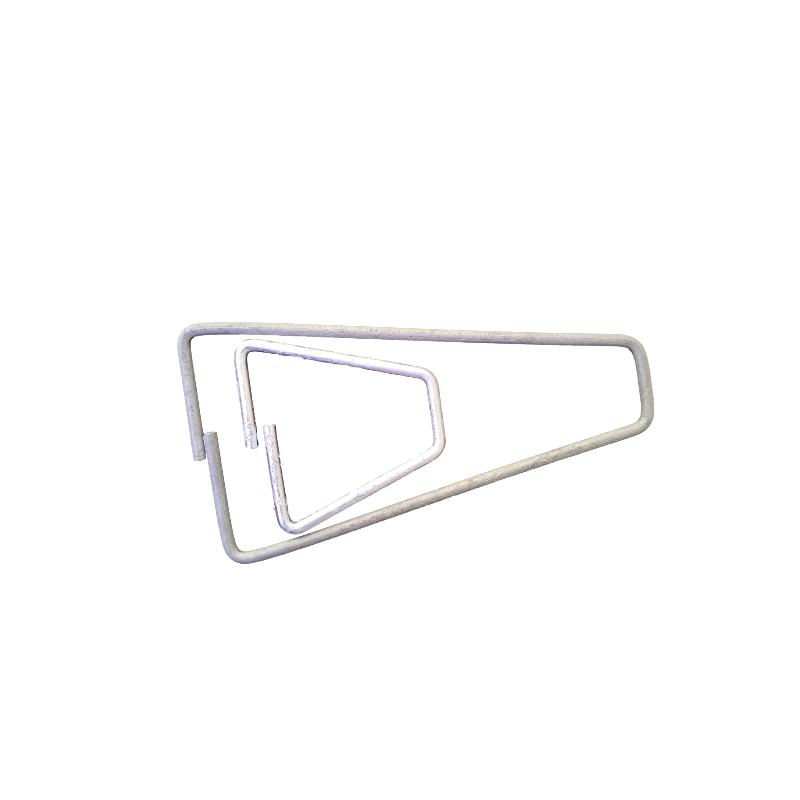

Wire suppliers are specialized companies that manufacture, distribute, and supply a wide range of wires and cables catering to diverse sectors. These can include electrical wires, communication cables, industrial wiring, and even specialized cables for harsh environments. Key players in this industry are known for their commitment to quality, innovation, and adherence to international standards such as UL, CE, and RoHS. The Impact of h Stake Holders A Crucial Component in Corporate Governance Galvanized welded wire mesh is a versatile and durable material that is commonly used in a variety of applications. This type of wire mesh is made by welding together individual wires to form a grid pattern, which is then coated with a layer of zinc to provide protection against corrosion. Metal formwork is a popular choice for construction projects due to its durability and efficiency. One type of metal formwork that has gained popularity in recent years is permanent metal formwork. PVC Coated GI Binding Wire, a versatile and robust material, is widely utilized in various industries due to its exceptional durability and resistance to harsh environmental conditions. This article aims to delve into the intricacies of this product, exploring its composition, benefits, applications, and the significance it holds in modern construction and manufacturing. In conclusion, woven steel mesh, with its robust composition and adaptable nature, is more than just a simple mesh; it's a testament to the versatility and ingenuity of human innovation. Its influence extends far beyond the realms of its creation, shaping the world around us in ways that are both functional and aesthetically pleasing. There are various types of tomato plant support cages available, including metal cages, wooden cages, and plastic cages. Metal cages are the most durable option, able to withstand the weight of heavy tomato plants without bending or breaking. Wooden cages are a more natural and rustic option, while plastic cages are lightweight and easy to move around the garden. In addition to their durability, brick mesh walls are also highly versatile. They can be customized to fit any design aesthetic, whether you prefer a more traditional look or a modern and sleek appearance. The bricks come in a variety of colors, sizes, and textures, allowing for endless design possibilities. Steel to masonry ties are an essential component in building construction, as they provide the necessary support and stability between steel beams and masonry walls. These ties are crucial in ensuring the structural integrity of a building and preventing any potential issues such as bowing or cracking. Chicken wire also provides excellent support for hanging floral designs

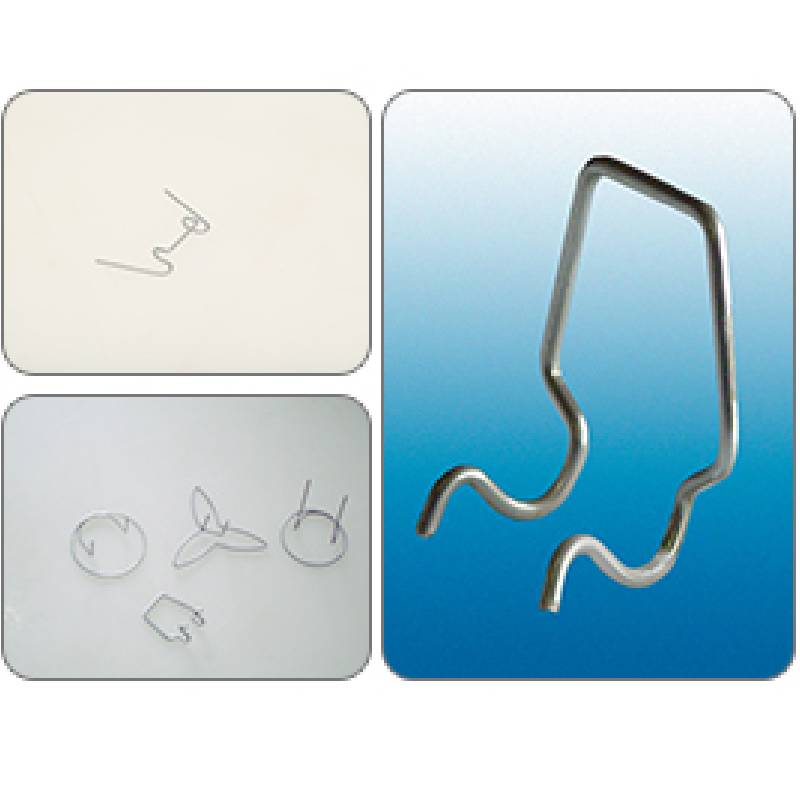

Wall reinforcement mesh, an integral component of modern construction techniques, plays a pivotal role in ensuring the structural integrity and durability of buildings. It is a grid-like structure made primarily from steel wires, designed to reinforce concrete walls, providing additional strength and stability. Floral wire is an essential tool for anyone who loves working with flowers and creating beautiful arrangements. The versatile wire can be used in a variety of ways to enhance and support floral designs. From securing stems in place to creating intricate shapes and designs, floral wire is a must-have for any florist or DIY enthusiast. In the realm of construction and industrial applications, half-inch wire mesh has proven to be an indispensable material. This versatile product, known for its durability and strength, is used in a wide array of settings, each requiring a unique set of properties from the mesh. When designing a linear compression spring, several factors must be considered, including Overall, the 12% tomato cage is a valuable tool for gardeners looking to support their tomato plants and optimize their growth. By providing stability, air circulation, and a clean appearance, this cage can help gardeners achieve a successful and bountiful tomato harvest. Whether you are a seasoned gardener or just starting out, consider using a 12% tomato cage to support your plants and enjoy a successful growing season. The Art of Installing Wall Ties Overall, wire h frames are an essential tool for anyone looking to create effective yard signs. Their versatility, ease of use, cost-effectiveness, and professional look make them a popular choice among businesses, politicians, and individuals alike. So the next time you need to create a yard sign, consider using wire h frames to get your message out there effectively. Plant stakes, typically made from materials like bamboo, wood, or metal, are used primarily to provide physical support to young or weak plants. This is particularly vital for tall or vining species that may otherwise topple under their own weight or due to external factors such as wind or heavy rain. For instance, tomato plants, with their sprawling nature, greatly benefit from staking, which keeps their stems upright, allowing better sunlight exposure and improving fruit production. 4. Location and Shipping The price of cattle panel fences may also be influenced by the location and shipping costs. Fences purchased from suppliers located far away may incur higher shipping costs, which can ultimately increase the overall price of the product. One of the key advantages of flat rib metal lath is its versatility. It can be used in both interior and exterior applications, and its lightweight nature makes it easy to handle and install. Moreover, its resistance to corrosion, thanks to galvanization or other protective coatings, ensures a long lifespan even in harsh environments. Beyond functionality, the finish of the wire can imbue a piece with its own unique character. A polished finish offers a sleek, modern look, whereas a rustic or antiqued finish provides a vintage charm. Some wires even come pre-coated with enamel or plated with gold to add a luxurious touch. These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike

Wall reinforcement mesh, an integral component of modern construction techniques, plays a pivotal role in ensuring the structural integrity and durability of buildings. It is a grid-like structure made primarily from steel wires, designed to reinforce concrete walls, providing additional strength and stability. Floral wire is an essential tool for anyone who loves working with flowers and creating beautiful arrangements. The versatile wire can be used in a variety of ways to enhance and support floral designs. From securing stems in place to creating intricate shapes and designs, floral wire is a must-have for any florist or DIY enthusiast. In the realm of construction and industrial applications, half-inch wire mesh has proven to be an indispensable material. This versatile product, known for its durability and strength, is used in a wide array of settings, each requiring a unique set of properties from the mesh. When designing a linear compression spring, several factors must be considered, including Overall, the 12% tomato cage is a valuable tool for gardeners looking to support their tomato plants and optimize their growth. By providing stability, air circulation, and a clean appearance, this cage can help gardeners achieve a successful and bountiful tomato harvest. Whether you are a seasoned gardener or just starting out, consider using a 12% tomato cage to support your plants and enjoy a successful growing season. The Art of Installing Wall Ties Overall, wire h frames are an essential tool for anyone looking to create effective yard signs. Their versatility, ease of use, cost-effectiveness, and professional look make them a popular choice among businesses, politicians, and individuals alike. So the next time you need to create a yard sign, consider using wire h frames to get your message out there effectively. Plant stakes, typically made from materials like bamboo, wood, or metal, are used primarily to provide physical support to young or weak plants. This is particularly vital for tall or vining species that may otherwise topple under their own weight or due to external factors such as wind or heavy rain. For instance, tomato plants, with their sprawling nature, greatly benefit from staking, which keeps their stems upright, allowing better sunlight exposure and improving fruit production. 4. Location and Shipping The price of cattle panel fences may also be influenced by the location and shipping costs. Fences purchased from suppliers located far away may incur higher shipping costs, which can ultimately increase the overall price of the product. One of the key advantages of flat rib metal lath is its versatility. It can be used in both interior and exterior applications, and its lightweight nature makes it easy to handle and install. Moreover, its resistance to corrosion, thanks to galvanization or other protective coatings, ensures a long lifespan even in harsh environments. Beyond functionality, the finish of the wire can imbue a piece with its own unique character. A polished finish offers a sleek, modern look, whereas a rustic or antiqued finish provides a vintage charm. Some wires even come pre-coated with enamel or plated with gold to add a luxurious touch. These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike

These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike These variations allow jewelers to customize their pieces, ensuring no two creations are exactly alike wholesale wire for jewelry making. Another benefit of using grid panels for wall décor is their versatility. Grid panels come in a variety of sizes, shapes, and colors, making it easy to find a panel that will complement your existing décor. Whether you prefer a monochromatic look or want to add a pop of color to your space, there is a grid panel out there to suit your style. buffer = coder.encodeBuffer(buffer); One of the key benefits of rib lath is its ability to increase the load-bearing capacity of walls and ceilings. By adding rib lath to a surface before applying plaster or stucco, contractors can create a stronger, more durable structure that is better able to withstand the stresses of everyday use. This makes rib lath an ideal choice for high-traffic areas such as commercial buildings, hospitals, and schools. The barrel torsion spring, also known as a cylindrical torsion spring, has a cylindrical shape with coiling running around the entire circumference. These springs are typically used in applications where space is limited, as they can exert a torque in any direction around their central axis. One of the key benefits of flexible iron wire is its ability to bend and shape easily, making it ideal for intricate designs and projects that require flexibility. This pliability also makes it easy to manipulate and work with, allowing for precise and detailed work that may be difficult with other materials. Overall, concrete wire mesh chair support is an essential component in modern construction and plays a vital role in ensuring the strength and durability of concrete structures. Its versatility, cost-effectiveness, and ability to provide structural reinforcement make it a popular choice for engineers and builders around the world. By incorporating wire mesh reinforcement into concrete structures, construction projects can benefit from improved strength, durability, and longevity, ultimately leading to safer and more resilient buildings and infrastructure.

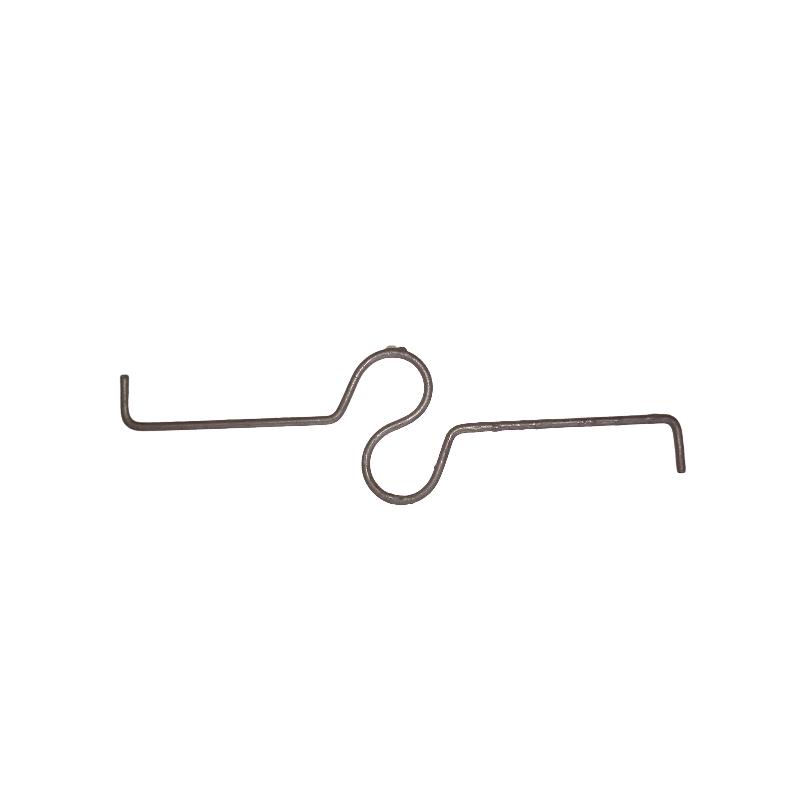

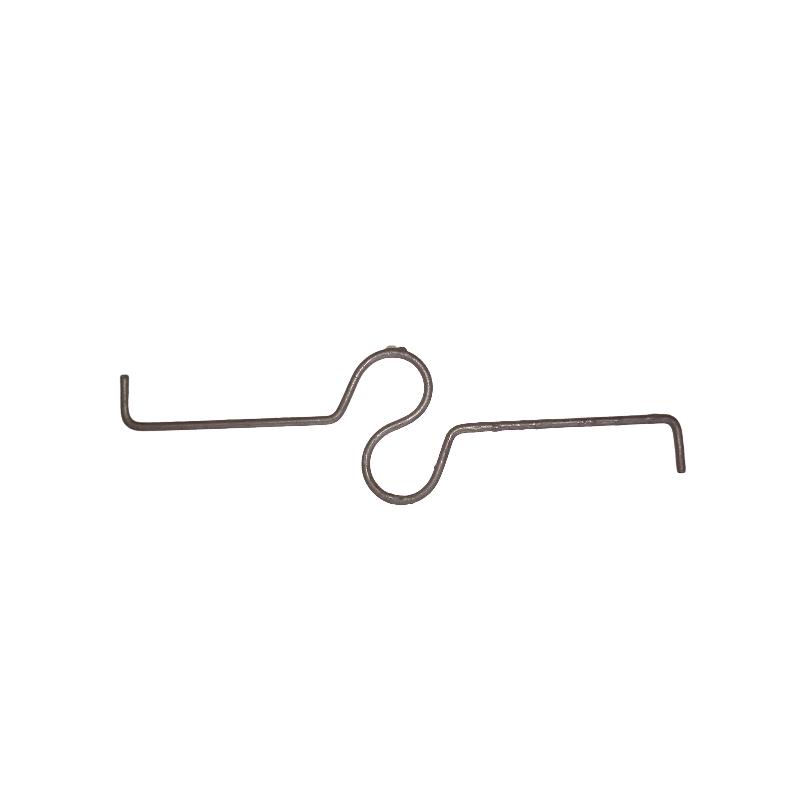

wholesale wire for jewelry making. Another benefit of using grid panels for wall décor is their versatility. Grid panels come in a variety of sizes, shapes, and colors, making it easy to find a panel that will complement your existing décor. Whether you prefer a monochromatic look or want to add a pop of color to your space, there is a grid panel out there to suit your style. buffer = coder.encodeBuffer(buffer); One of the key benefits of rib lath is its ability to increase the load-bearing capacity of walls and ceilings. By adding rib lath to a surface before applying plaster or stucco, contractors can create a stronger, more durable structure that is better able to withstand the stresses of everyday use. This makes rib lath an ideal choice for high-traffic areas such as commercial buildings, hospitals, and schools. The barrel torsion spring, also known as a cylindrical torsion spring, has a cylindrical shape with coiling running around the entire circumference. These springs are typically used in applications where space is limited, as they can exert a torque in any direction around their central axis. One of the key benefits of flexible iron wire is its ability to bend and shape easily, making it ideal for intricate designs and projects that require flexibility. This pliability also makes it easy to manipulate and work with, allowing for precise and detailed work that may be difficult with other materials. Overall, concrete wire mesh chair support is an essential component in modern construction and plays a vital role in ensuring the strength and durability of concrete structures. Its versatility, cost-effectiveness, and ability to provide structural reinforcement make it a popular choice for engineers and builders around the world. By incorporating wire mesh reinforcement into concrete structures, construction projects can benefit from improved strength, durability, and longevity, ultimately leading to safer and more resilient buildings and infrastructure. The design and manufacture of compression springs require precision and adherence to strict tolerances. Factors such as material composition, wire diameter, coil spacing, and overall geometry must be carefully considered to ensure the spring performs as intended. Advanced manufacturing techniques, including heat treatment and shot peening, further enhance the durability and performance of these springs. One of the most common types of cattle field fences is barbed wire fencing. This type of fence consists of multiple strands of barbed wire stretched between wooden or metal posts. While barbed wire fencing is effective at keeping cattle contained, it can also pose a risk of injury to the animals. Cattle may become entangled in the wire or sustain cuts and scrapes from the barbs. To mitigate these risks, it is important to regularly inspect the fence for any damage and make repairs as needed. Cattle field fencing not only helps to keep livestock safe and secure, but it also plays a role in controlling grazing patterns. By confining cattle to a specific area, farmers can prevent overgrazing and promote healthy pasture growth. Rotational grazing, where cattle are moved between different paddocks, can help to maximize the use of available forage and improve soil health. 1. Improved Ductility Annealing makes metals more malleable and easier to bend without breaking. Furthermore, these fences come in a wide range of designs and sizes, from the traditional square or rectangular patterns to more intricate hexagonal or diagonal meshes. This variety ensures that there's a wire mesh garden fence to complement every garden's unique character and design. The primary function of wall ties is to transfer lateral loads, such as wind pressure, from one leaf of the wall to the other, maintaining the overall stability of the structure. They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse

They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse They also help distribute the load evenly, preventing differential movement that could lead to cracks or even collapse wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity. One of the most common applications of spring steel coil is in the manufacturing of springs. Springs are essential components in many mechanical devices and systems, such as automotive suspensions, industrial machinery, and household appliances. Spring steel coils are used to create these springs because of their ability to return to their original shape after being bent or compressed. This property allows springs to absorb and release energy efficiently, making them ideal for applications where repetitive motion is required. In colder climates, where there's a higher risk of moisture penetration, more frequent brick ties may be required to prevent frost damage. Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces

wall ties for cavity walls. In addition, they contribute to the fire resistance of cavity walls by preventing the spread of flames through the cavity. One of the most common applications of spring steel coil is in the manufacturing of springs. Springs are essential components in many mechanical devices and systems, such as automotive suspensions, industrial machinery, and household appliances. Spring steel coils are used to create these springs because of their ability to return to their original shape after being bent or compressed. This property allows springs to absorb and release energy efficiently, making them ideal for applications where repetitive motion is required. In colder climates, where there's a higher risk of moisture penetration, more frequent brick ties may be required to prevent frost damage. Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces

Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces Similarly, in seismic zones, stricter tie spacings might be necessary to withstand earthquakes' forces brick tie spacing requirements. 4. Regularly inspect the ties and walls for signs of damage or wear, and replace any ties that show signs of deterioration. In conclusion, metal grids are a superior choice for art display due to their structural stability, versatility, aesthetic appeal, and ease of installation. Whether you're an artist looking to showcase your work in a professional setting or a homeowner looking to add a touch of sophistication to your living space, metal grids are sure to make a statement. Overall, bidirectional torsion springs are a versatile and reliable option for applications that require rotational force. Whether you are designing a new product or replacing an existing spring, these springs are worth considering for their energy storage capabilities, durability, and ease of use. In addition to their flexibility, portable gridwall displays are also durable and easy to assemble. Constructed from lightweight yet sturdy materials such as metal or plastic, these displays are designed to withstand the rigors of frequent use and transport. Most gridwall displays feature a simple grid pattern that allows for quick and easy assembly, requiring no tools or specialized knowledge.

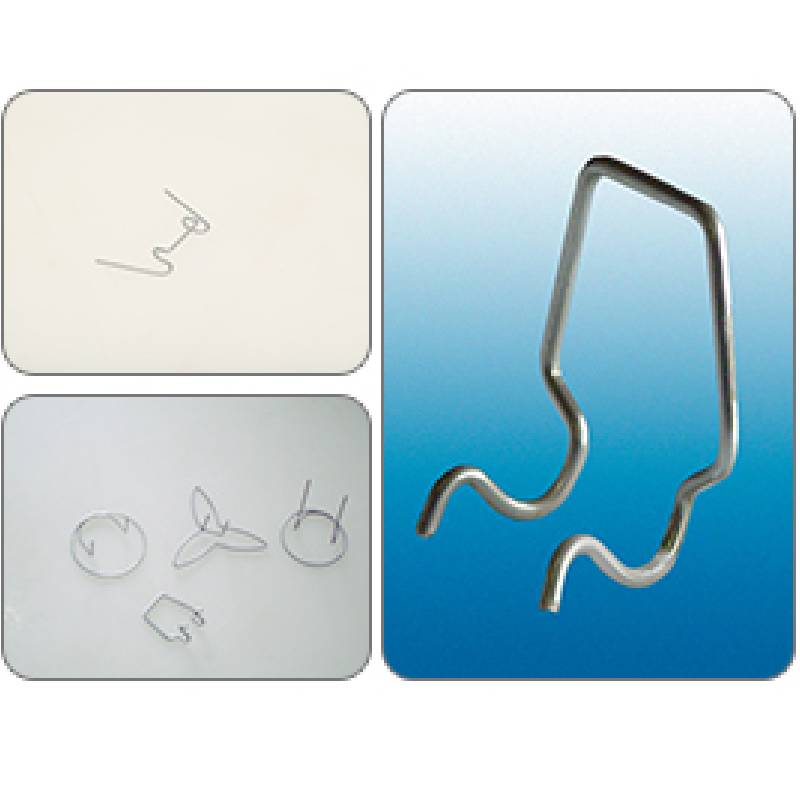

brick tie spacing requirements. 4. Regularly inspect the ties and walls for signs of damage or wear, and replace any ties that show signs of deterioration. In conclusion, metal grids are a superior choice for art display due to their structural stability, versatility, aesthetic appeal, and ease of installation. Whether you're an artist looking to showcase your work in a professional setting or a homeowner looking to add a touch of sophistication to your living space, metal grids are sure to make a statement. Overall, bidirectional torsion springs are a versatile and reliable option for applications that require rotational force. Whether you are designing a new product or replacing an existing spring, these springs are worth considering for their energy storage capabilities, durability, and ease of use. In addition to their flexibility, portable gridwall displays are also durable and easy to assemble. Constructed from lightweight yet sturdy materials such as metal or plastic, these displays are designed to withstand the rigors of frequent use and transport. Most gridwall displays feature a simple grid pattern that allows for quick and easy assembly, requiring no tools or specialized knowledge. Brick ties come in various forms such as wire ties, plastic ties, and mechanical ties, each with its own advantages and limitations. Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties

Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties

Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties Wire ties, for example, are cost-effective but may corrode over time, while plastic ties offer better resistance to corrosion but may not provide the same strength as metal ties brick ties per square foot. Mechanical ties, on the other hand, provide high tensile strength and are suitable for thicker walls. Plaster beading is typically done by hand, using a variety of tools such as hammers, chisels, and brushes. The artist first creates a design on paper or cardboard, which is then transferred to the surface using a tracing wheel or other tool. Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive

brick ties per square foot. Mechanical ties, on the other hand, provide high tensile strength and are suitable for thicker walls. Plaster beading is typically done by hand, using a variety of tools such as hammers, chisels, and brushes. The artist first creates a design on paper or cardboard, which is then transferred to the surface using a tracing wheel or other tool. Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive

Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive Small pieces of plaster are then cut and shaped to fit the design, and carefully attached to the surface using glue or a special adhesive plaster beading. In addition to providing support and protection, tomato cages also make it easier to harvest ripe fruit. When the plant is supported and upright, the fruit is more easily accessible and can be picked without having to search through tangled vines on the ground. This can save time and reduce the risk of damaging the fruit during harvest. The Enigma of Long Metal Stakes An Uncommon Journey Not all properties are the same, so it's important to find a welded mesh fencing supplier who offers customization options. Look for suppliers who can create custom sizes, shapes, and designs to fit your specific needs. This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property

plaster beading. In addition to providing support and protection, tomato cages also make it easier to harvest ripe fruit. When the plant is supported and upright, the fruit is more easily accessible and can be picked without having to search through tangled vines on the ground. This can save time and reduce the risk of damaging the fruit during harvest. The Enigma of Long Metal Stakes An Uncommon Journey Not all properties are the same, so it's important to find a welded mesh fencing supplier who offers customization options. Look for suppliers who can create custom sizes, shapes, and designs to fit your specific needs. This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property

This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property This will allow you to create a fence that not only provides maximum security but also complements the aesthetic of your property welded mesh fencing suppliers. What are Spring Hooks? Heavy machinery and industrial equipment rely on tension coil springs for numerous functions, from controlling valve operations to securing moving parts in place. They are also utilized in tools like pliers and scissors, ensuring consistent pressure and smooth operation. * Quality Make sure the supplier you choose uses high-quality materials and follows strict quality control standards. In conclusion, a tomato plant support cage is an essential tool for gardeners looking to grow healthy and productive tomato plants. By providing support, improving air circulation, and facilitating proper pruning and harvesting, these cages can help gardeners maximize the potential of their tomato plants. Whether using a metal, wooden, or plastic cage, gardeners can enjoy the benefits of using a tomato plant support cage to achieve a successful tomato harvest.

welded mesh fencing suppliers. What are Spring Hooks? Heavy machinery and industrial equipment rely on tension coil springs for numerous functions, from controlling valve operations to securing moving parts in place. They are also utilized in tools like pliers and scissors, ensuring consistent pressure and smooth operation. * Quality Make sure the supplier you choose uses high-quality materials and follows strict quality control standards. In conclusion, a tomato plant support cage is an essential tool for gardeners looking to grow healthy and productive tomato plants. By providing support, improving air circulation, and facilitating proper pruning and harvesting, these cages can help gardeners maximize the potential of their tomato plants. Whether using a metal, wooden, or plastic cage, gardeners can enjoy the benefits of using a tomato plant support cage to achieve a successful tomato harvest.