Links:

Galvanized steel nails are steel nails that have been coated with a layer of zinc to protect them from corrosion. The process of galvanization involves immersing the nails in molten zinc, which forms a protective layer that prevents moisture from reaching the steel beneath. This quality makes galvanized nails an excellent choice for use in environments that are exposed to the elements, such as roofing, fencing, and outdoor furniture.

The sulphur trioxide formed is first made to react with concentrated sulphuric acid. Sulphur trioxide cannot be dissolved in water directly as it leads to the formation of fog. The product obtained after this reaction is known as oleum. The oleum obtained is then dissolved in water to obtain concentrated sulphuric acid.

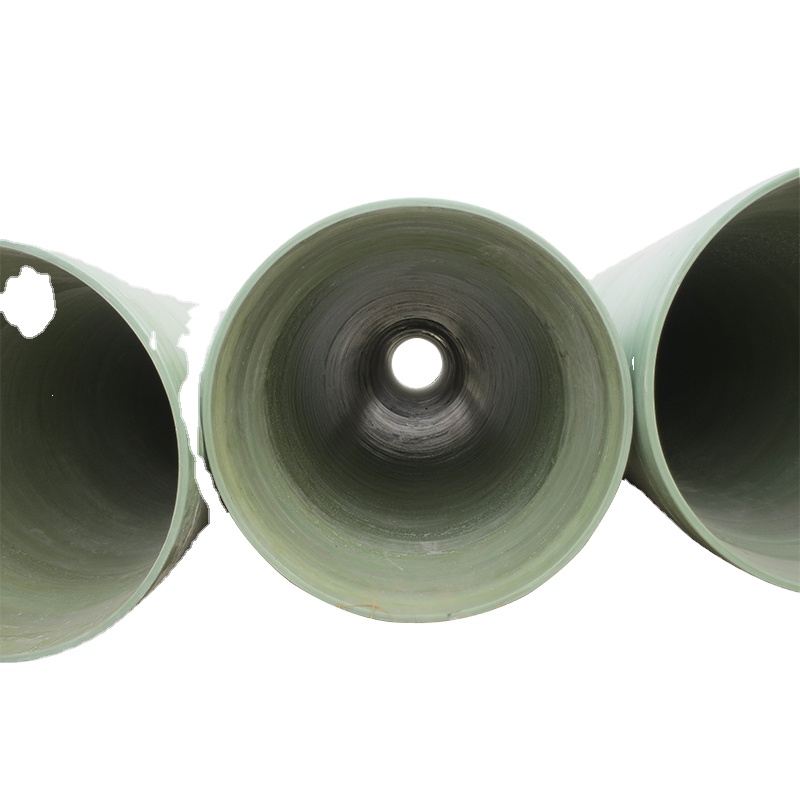

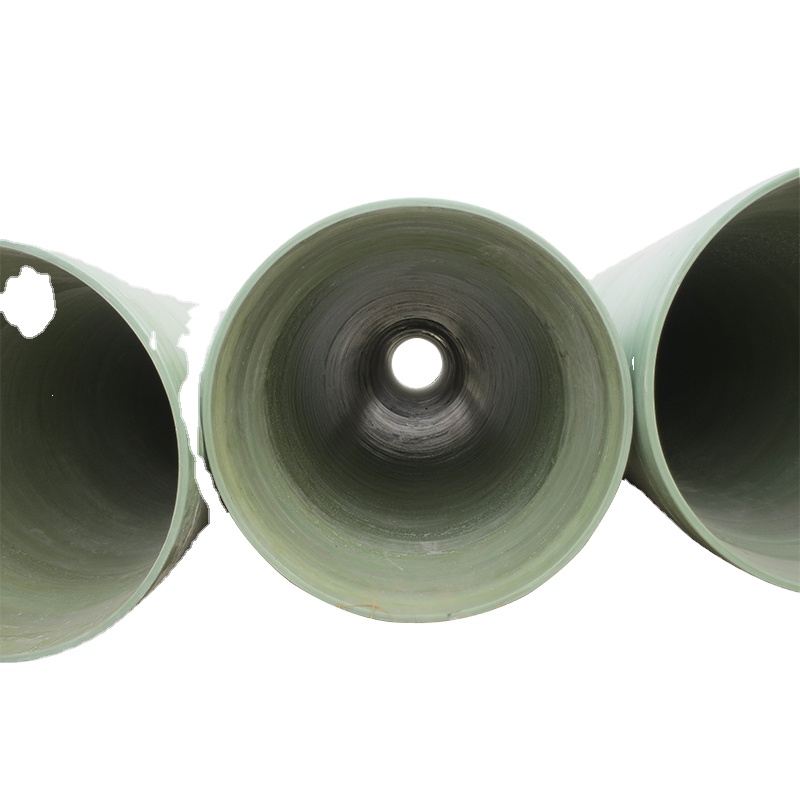

One of the key benefits of fiberglass septic tanks is their lightweight and easy installation process. Unlike traditional concrete septic tanks, fiberglass tanks are lighter in weight and can be easily transported and installed on-site. This not only reduces the labor and time required for installation but also minimizes the impact on the environment during the installation process.1. Longevity The protective PVC layer significantly extends the lifespan of the wire compared to standard steel options, making it a cost-effective choice over time.

Furthermore, SS tanks are highly efficient in terms of storage capacity and space utilization. These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations

These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations

These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations ss tanks for sale. This allows businesses to maximize their storage capacity while minimizing the amount of space required for tank installation. The Art of Nail Making Exploring the Use of Steel Wire

ss tanks for sale. This allows businesses to maximize their storage capacity while minimizing the amount of space required for tank installation. The Art of Nail Making Exploring the Use of Steel Wire Conclusion

In the context of roofing applications, the BWG9X2.5% rubber washer roofing nails offer a significant advantage over conventional nails. Their superior holding power reduces the likelihood of nails popping up over time, a common issue in roofing. Moreover, their installation is relatively straightforward, requiring minimal effort and tools, making them a favorite among professionals and DIY enthusiasts alike.

Corrosion Resistance

Applications in Various Industries

- Water Treatment These tanks are suitable for storing potable water and wastewater due to their structural integrity and safety standards, making them a reliable option for municipalities and industries.

The electrical industry capitalizes on the non-conductive properties of this fiberglass variant

Do-it-yourself enthusiasts and professionals alike should be wary of deals that seem too good to be true. It is imperative to balance cost with quality to ensure the longevity and safety of the structures being built. Reading reviews and seeking recommendations from industry professionals can provide valuable insights into which suppliers offer the best products.

Lastly, stainless steel is considered an environmentally friendly option due to its recyclability. While the initial cost may be higher than other materials, the environmental benefits and the potential for lower total lifecycle costs can be attractive to eco-conscious consumers and businesses.

Durability and Strength

The welded rabbit cage wire mesh also provides a secure platform for rabbit enrichment

welded rabbit cage wire mesh. Its sturdy structure can withstand the weight of various accessories like platforms, ladders, and toys, encouraging exercise and mental stimulation for your pets. Additionally, the mesh's uniform spacing allows for easy access to food and water bowls, as well as facilitating cleaning and maintenance tasks.

welded rabbit cage wire mesh. Its sturdy structure can withstand the weight of various accessories like platforms, ladders, and toys, encouraging exercise and mental stimulation for your pets. Additionally, the mesh's uniform spacing allows for easy access to food and water bowls, as well as facilitating cleaning and maintenance tasks. What is Wire Mesh?

As we look towards the future, the focus on sustainability within the beauty industry is also affecting nail care. Eco-friendly nail products, which are free from harmful chemicals, are gaining traction among consumers concerned about their health and the environment. Brands are developing polishes that are cruelty-free, vegan, and made from non-toxic ingredients, thus making a responsible choice without compromising on style.

The significance of the fiberglass production line extends beyond mere manufacturing efficiency. It plays a vital role in meeting the rising demand for sustainable materials. As industries strive towards greener practices, fiberglass, known for its recyclability and lower environmental footprint compared to traditional materials, has become a preferred choice. Moreover, innovations within the production line, including the use of recycled glass as raw material, reflect a shift towards sustainable manufacturing practices.

1. Material Type Wire mesh is available in various materials, including stainless steel, galvanized steel, aluminum, and PVC-coated wire. Each material has its unique properties, cost implications, and suitability for specific applications. For instance, stainless steel wire mesh is usually more expensive due to its corrosion resistance and durability compared to galvanized or PVC-coated options.

- Energy The renewable energy sector employs FRP for wind turbine blades and components, leveraging their strength-to-weight advantage for enhanced performance.

In addition, frp machines are known for their efficiency and cost-effectiveness

. The manufacturing process is typically automated, which helps reduce labor costs and increase production speed. Furthermore, frp materials are relatively inexpensive compared to other materials such as steel or aluminum, making them a cost-effective option for many applications.Furthermore, technological advancements have seen wire mesh being utilized in high-tech applications. In electronics, it's used in screens and shielding to prevent electromagnetic interference. In aerospace, its lightweight yet strong nature makes it suitable for certain aircraft components. Umbrella nails are a type of roofing nail that is commonly used in construction projects in China. These nails are designed to securely fasten roofing materials to the underlying structure and provide a weather-tight seal. If you are in the market for umbrella nails, it is important to understand the pricing and quality options available in China. In this article, we will provide you with a comprehensive overview of China's umbrella nails price list and help you make an informed decision.

2. Length and Gauge The length and thickness (gauge) of the nails should be appropriate for the materials being joined. Longer nails provide better hold for thicker materials, while shorter nails are sufficient for lighter applications.

In a typical thermal power plant, steam is produced by heating water using fossil fuels such as coal, oil, or natural gas. This high-pressure steam is then directed through turbines, which spin and generate electricity. However, as the steam passes through the turbines, it loses energy and begins to cool down. To prevent this cooled steam from condensing back into water and reducing the plant's efficiency, it must be expelled into the atmosphere.

The Manufacturing Process

2. Gas-Powered Nail Guns These tools use a combination of gas cartridges and battery power to propel nails. Their portability makes them suitable for remote job sites where an air compressor isn’t feasible. However, users must consistently manage gas supply and battery charging.

Additionally, sourcing practices play a critical role. Nails manufactured using sustainable methods or those that are produced in smaller batches often carry a higher price tag due to their quality assurance and ethical production processes. Buyers should consider both the immediate costs and the long-term value when selecting nails for their projects.

best pure iron nails price

Fibreglass grating has emerged as a game-changing material in various sectors, owing to its unique properties and advantages over traditional materials. This composite material, primarily made from fibreglass and resin, provides exceptional strength, durability, and corrosion resistance, making it an ideal choice for a multitude of applications, particularly in industrial settings.

The production of wooden nails involves a careful crafting process

. Artisans typically select high-quality hardwoods such as oak, hickory, or maple for their durability and strength. The wood is then cut into the desired shape and size, often tapered to fit snugly into a pre-drilled hole. When used in construction, the natural elasticity of wood allows for a holding power that can rival metal nails, especially in applications where flexibility is required.Furthermore, top stainless steel water tanks are known for their high quality construction. These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come

These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come

These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come These tanks are made with precision and attention to detail, ensuring that they are free from defects and will perform reliably for years to come top stainless steel water tank. This high level of craftsmanship sets top stainless steel water tanks apart from other options on the market, making them a top choice for discerning consumers who demand the best.

top stainless steel water tank. This high level of craftsmanship sets top stainless steel water tanks apart from other options on the market, making them a top choice for discerning consumers who demand the best. In today's world, security is a paramount concern for both residential and commercial properties. One of the most effective deterrents against intrusions and trespassers is the use of advanced fencing solutions. Among these, electro galvanized razor barbed wire stands out as a formidable option, combining strength, durability, and psychological deterrence.

Moreover, galvanized steel nails offer excellent versatility

2. Consistency and Strength The welding process used in their manufacture ensures that each nail remains consistent in its size and shape, which is essential for maintaining structural integrity. The strength of the nails also ensures that they can withstand heavy loads, making them suitable for pallet construction, which often requires durability and reliability.

In conclusion, the chain link fence industry in China is thriving, driven by a combination of domestic infrastructure projects, heightened safety consciousness, and a growing international presence. As technology advances and consumer preferences evolve, Chinese manufacturers are likely to continue innovating and adapting to maintain their leading position in the global fencing market. The Versatile Steel Storage Tank A Modern Marvel in Industrial Solutions

5. Barbed Wire This specialized type of iron wire is designed for security and fencing, featuring barbs that deter trespassers.

Overall, fiberglass water storage tanks offer a durable, lightweight, cost-effective, and versatile solution for storing water. Whether used for residential, commercial, or industrial purposes, fiberglass tanks provide a reliable and long-lasting way to store water safely. With their many benefits and advantages, it's no wonder why fiberglass water storage tanks are a popular choice among consumers and businesses alike.

The Significance and Development of Shijiazhuang Iron and Steel Industry

Finishing nails may be small, but their impact on manufacturing and construction is substantial. As industries aim for higher standards of craftsmanship and aesthetic appeal, the demand for quality finishing nails continues to grow. The manufacturing processes that produce these vital components are intricate and require precision to ensure that they meet the rigorous standards of various applications. With advancements in technology and materials, the future of finishing nails looks promising, supporting both traditional craftsmanship and modern design innovations. As such, these seemingly simple fasteners play a crucial role in the broader narrative of quality and aesthetics in the manufacturing world.

The Power of Coiled Clout Nails An Unsung Hero in Construction

Eco-Friendly Option

● The pultrusion process offers virtually endless options for customization to meet various structural and design requirements.

Disadvantages of Fiberglass Septic Tanks

In the automotive industry, fiberglass tubes and rods are used in the production of automotive components such as drive shafts, steering columns, and suspension components. Their high strength and durability make them a reliable option for withstanding the rigors of daily driving.