Vegetarian HPMC capsules are made from 100% plant-sourced ingredients i.e. hypromellose that digest easily. They are perfectly healthy and do not contain any animal-by products or animal-borne contaminants.

They also do not trigger any allergic reaction or cause side effects, even on prolonged use. Typically, veggie capsules are vegan, Halal, and Kosher certified. That satisfies consumers with religious considerations.

Manufacturers produce these capsules in cGMP-approved facilities and follow a rigorous quality assurance process in their operations. Capsuline manufacturing facilities are cGMP certified and hold IS0-100 quality control certification to guarantee the traceability of materials. Also, all raw materials used are FDA 'Generally Regarded As Safe' (GRAS)-standard.

You can also choose the desired variety of these capsules that possess your preferred type of colorant, opacifier, or coating material.

Nevertheless, veggie capsules promote your health by enhancing the way active drugs are absorbed and utilized in your body.

. The resulting almond milk will have a rich and creamy texture with a subtle vanilla flavor.

A key characteristic of HPMC is its ability to form a gel in aqueous solutions, making it an effective thickening and binding agent. It is non-ionic, which means it doesn't carry a charge in solution, facilitating its use in a variety of formulations without causing ionic interference. Furthermore, HPMC has excellent film-forming capabilities, contributing to its widespread application in different fields.

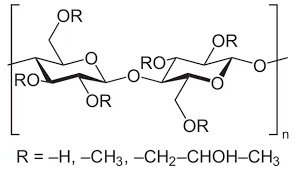

HPMC is synthesized by reacting cellulose with propylene oxide and methyl chloride. The resultant polymer comprises hydroxypropyl and methyl groups attached to the cellulose backbone. The degree of substitution of these groups can be adjusted during the manufacturing process, which affects the physical and chemical properties of the final product. As a result, HPMC can vary in viscosity, solubility, and thermal stability, making it adaptable for specific applications.

The manufacturing process of hydroxyethyl cellulose is a complex yet well-defined procedure that transforms cellulose into a functional and versatile polymer. Through careful selection of raw materials, precise control of reaction conditions, and stringent quality assurance protocols, manufacturers can produce HEC that meets the high standards demanded by various industries. Its wide range of applications as a thickening agent, emulsifier, and stabilizer continues to drive its demand in the market, showcasing the importance of efficient and effective manufacturing processes in the chemical industry.

In summary, China HPMC powder plays a crucial role in various industries with its multifunctional properties. As production techniques continue to advance, and the demand for eco-friendly materials increases, HPMC powder’s relevance and applications will likely expand further. Its diverse uses in construction, pharmaceuticals, food, cosmetics, and personal care products underscore its importance in contemporary manufacturing processes. With continued investment in technology and quality, Chinese manufacturers are poised to remain at the forefront of the global HPMC powder market.

The cosmetic and personal care industry also benefits significantly from HPMC. Its ability to form a gel-like consistency makes it a common ingredient in lotions, creams, and other skincare products. HPMC helps to stabilize emulsions, ensuring that the oil and water components remain mixed. Additionally, its water-retention properties contribute to skin hydration, making it a valuable asset in moisturizing products. HPMC is often found in products targeting sensitive skin due to its hypoallergenic and non-irritating nature, making it suitable for a broad range of consumers.

Hydroxypropyl methyl cellulose (HPMC) is a versatile, non-toxic compound widely used in various industries, including pharmaceuticals, food, and cosmetics. Its application has recently extended into dietary supplements, where it serves multiple purposes, from acting as a thickener to serving as a binding agent. Understanding HPMC's properties and benefits is crucial for both manufacturers and consumers in the supplement industry.