Links:

- Slip modifier – Cellulose, Microcrystalline Cellulose

3. Water Retention The compound’s ability to retain water enhances the quality of products such as mortars, plasters, and other construction materials. This property helps maintain moisture levels, leading to improved workability and durability.

Another area where RDP polymers are making a notable impact is in the realm of construction materials. By incorporating RDP polymers into cement and concrete mixtures, builders can enhance workability and adhesion. The outcome is improved strength and durability in construction applications, reducing the need for frequent repairs and maintenance. This innovation aligns with industry trends towards more durable and sustainable building practices.

- Thickening Agent Its ability to increase viscosity allows for use as a thickening agent, essential in cosmetics and food products to achieve the desired consistency.

Conclusion

Etherification Reaction

In the food industry, HPMC serves as a popular food additive. Its emulsifying and stabilizing properties make it ideal for use in a variety of products, including sauces, dressings, and baked goods. By adding HPMC, manufacturers can improve the texture and consistency of food products, enhancing their appeal to consumers. Furthermore, HPMC is often used as a fat replacer in low-fat and reduced-calorie products, allowing food manufacturers to create healthier options without sacrificing taste or texture.

hpmc ingredient

4. Regulatory Factors

What is Hydroxypropyl Methylcellulose?

HPMC is utilized in an array of applications, owing to its unique properties. In the pharmaceutical industry, it acts as a controlled-release agent in drug formulations, ensuring a steady release of medication in the body. Its ability to form viscous solutions makes it an essential component in formulations like oral suspensions and controlled-release tablets.

Conclusion

3. Temperature Temperature changes can affect the viscosity of HEC solutions. Typically, increased temperature leads to a decrease in viscosity; this behavior must be taken into account during application and storage.

hydroxyethyl cellulose viscosity

Moreover, HPMC has been instrumental in the construction industry. When added to cement-based products, it improves workability, water retention, and adhesion. These properties are vital for achieving stronger and more durable construction materials. HPMC-modified mortars and plasters have been associated with enhanced performance characteristics, making them preferable choices for modern construction applications.

One of the key benefits of RDP is its ease of use. With RDP, users can connect to a remote computer with just a few clicks, without the need for complicated setup or configuration. This makes it an ideal solution for users who need to access their computers on the go or for IT professionals who need to troubleshoot issues on remote machines.

In addition to its pharmaceutical uses, HPMC is a crucial ingredient in the food industry. It functions as a thickening agent, stabilizer, and emulsifier, enhancing the texture and mouthfeel of various food products. It is often found in sauces, dressings, and baked goods, where it imparts desired viscosity without altering the flavor profile. Moreover, HPMC is compatible with gluten-free diets, making it a popular choice for formulating gluten-free products.

cellulose ether hpmc

Applications of HPMC in Mortar

In summary, Hydroxypropyl Methylcellulose (HPMC) embodies versatility across multiple industries due to its unique chemical properties and modifications. Its applications in pharmaceuticals, food, and construction demonstrate its significance as a functional ingredient. As the industries continue to evolve, the demand for high-performance materials like HPMC is likely to grow, further establishing its importance in contemporary manufacturing and formulation processes. Its non-toxic nature and adaptability make HPMC a vital component, contributing to innovations and advancements across various fields. As we move forward, understanding and utilizing HPMC's properties will remain essential for creating effective, safe, and sustainable products.

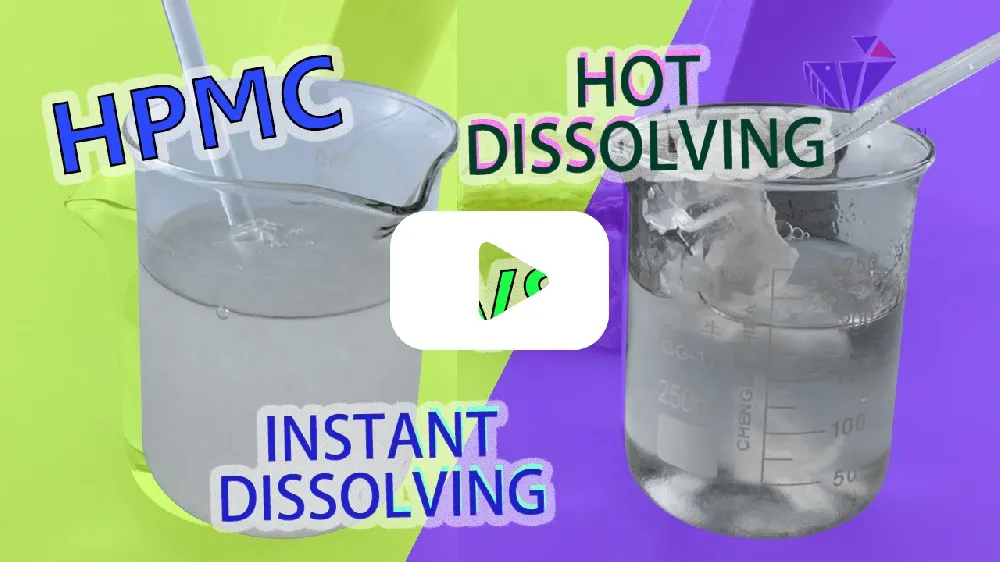

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose derivative that has found extensive applications across various industries, including pharmaceuticals, construction, food, and cosmetics. This article delves into the solubility characteristics of HPMC, highlighting its significance in formulation and product performance.

In the construction industry, hydroxypropyl methylcellulose is utilized as a thickener in cement-based products such as mortars, plasters, and tile adhesives. HPMC helps to improve workability, water retention, and adhesion of these materials. It also enhances the strength and durability of the final product by reducing cracking and shrinkage.

In conclusion, HPMC is not just a chemical additive; it is a driving force behind the modernization and sustainability of the construction industry in China. With its ability to improve the performance of building materials, support eco-friendly practices, and contribute to energy efficiency, HPMC stands as a testament to how innovation can shape the future of construction. As the industry continues to evolve, the role of HPMC will be pivotal in meeting the demands of modern architecture while fostering a sustainable environment for generations to come. As stakeholders across the board recognize its potential, HPMC is set to become an integral part of China’s construction landscape, supporting the nation’s growth in a responsible and effective manner.

It's also worth noting that HPMC is considered safe for use in food and pharmaceutical applications, as it is non-toxic and free from allergens. This safety profile adds to its attractiveness as an ingredient across various sectors.

- Food HEC acts as a thickener and emulsifier in the food industry, improving texture and consistency in products like sauces, dressings, and dairy alternatives.

3. Ethylene Oxide Reaction

Hydroxyethyl cellulose has several unique properties that make it a valuable ingredient in a wide range of products. It is highly water-soluble and can form transparent and stable gels in aqueous solutions. This makes it an excellent thickening agent for a variety of applications such as paints, adhesives, and personal care products.

In the realm of construction, redispersible powders are also used for their ability to improve the non-skid properties of flooring systems. By modifying the surface characteristics of flooring materials, redispersible polymers increase slip resistance, which is a crucial factor for safety in various environments, including commercial and industrial settings.

The applications of MHEC are vast and diverse, making it an essential component in many sectors.

1. Pharmaceuticals In the pharmaceutical industry, HEC is utilized as a thickening agent, binder, and stabilizer in liquid formulations like suspensions and gels. Its viscosity control ensures the proper release and absorption of active ingredients.

The production of hydroxypropyl methyl cellulose involves a series of chemical processes that modify natural cellulose, usually sourced from wood pulp or cotton. The primary steps include

With the increasing demand for HEC in various industries, there is a growing market for hydroxyethyl cellulose for sale. Manufacturers and suppliers are offering a wide range of HEC products to meet the diverse needs of their customers. Whether you are looking for HEC in powder form or in a liquid solution, there are plenty of options available in the market

hydroxyethyl cellulose for sale.

5. Applications in Formulation Understanding HPMC solubility through these charts is crucial for formulators in the pharmaceutical and food industries. For instance, in pharmaceutical tablets, HPMC is often used as a coating agent for controlled release. The specific solubility characteristics dictate how quickly the tablet breaks down and releases the active ingredient, ensuring proper dosing and effectiveness.

3. Cosmetic Ingredient Suppliers For individuals or businesses in the beauty industry, suppliers that focus specifically on cosmetic ingredients will often have hydroxyethyl cellulose available. These suppliers not only cater to large businesses but also to small formulators and DIY enthusiasts.

where can i buy hydroxyethyl cellulose

Acrylic redispersible polymer powder is also widely used in the construction industry. Acrylic redispersible polymer powder offers excellent adhesion to various substrates, good flexibility, and high water resistance

redispersible polymer powder types. It is often used in the formulation of exterior paints, plasters, sealants, and waterproofing membranes.

Innovation in HPMC Production

In conclusion, as a manufacturer of MHEC, it is crucial to prioritize quality control, flexibility, and innovation. By producing a high-quality product, tailoring it to meet the specific needs of customers, and staying informed about industry developments, manufacturers can ensure the success and growth of their business. Methyl Hydroxyethyl Cellulose is a valuable ingredient in many products, and its importance in various industries cannot be understated.

The benefits of using HPMC are numerous. Its eco-friendly nature appeals to consumers and manufacturers alike, as it is derived from renewable sources. HPMC is odorless, tasteless, and transparent, making it a desirable additive in various formulations without altering the inherent characteristics of the finished products.

The primary raw material for the production of hydroxyethyl cellulose is cellulose, typically sourced from wood pulp or cotton linter. The purity and source of cellulose are essential, as they significantly influence the quality of the final product. Additional reagents are also required, including ethylene oxide and alkaline catalysts, which facilitate the hydroxyethylation reaction.

Key Applications

The solubility of HPMC can also be influenced by the molecular weight of the polymer, with higher molecular weight HPMC typically being more soluble than lower molecular weight forms. This is because higher molecular weight HPMC has a greater number of hydroxypropyl groups, which can increase its compatibility with solvents.

Understanding the Solubility of Hydroxyethyl Cellulose

2. Pre-wet the HEC - Before adding HEC to water, it is recommended to pre-wet the polymer with a small amount of water. This will help to prevent clumping and ensure a smooth dispersion. - Natural Stone HPMC's properties help to protect sensitive stone surfaces during installation, ensuring they remain intact and aesthetically pleasing.

It can be used as a thickening agent in toothpaste manufacturing.

A typical HPMC factory in China employs advanced technologies to produce Hydroxypropyl Methylcellulose. The production process begins with the derivatization of cellulose, which is sourced from natural wood pulp. This cellulose is then reacted with propylene oxide and methyl chloride in a controlled environment to form HPMC. The entire process requires sophisticated equipment that ensures strict quality control, including precise temperature and pH monitoring, to produce HPMC that meets various viscosity and solubility requirements.

One of the most convenient ways to find hydroxyethyl cellulose is through online retailers. Platforms like Amazon, eBay, and specialized chemical supply websites often have a variety of HEC products available. When purchasing online, make sure to read customer reviews and check the specifications to ensure that you are buying the right grade for your needs.

2. Innovation and R&D The competitive nature of the pharmaceutical industry drives HPMC manufacturers to invest in research and development. Innovations in processing technologies, formulation techniques, and product customization help pharmaceutical companies address specific challenges. For instance, new HPMC formulations can improve the release profiles of drugs, enhancing bioavailability and patient compliance.

hpmc manufacturer

The adhesion properties of mortar are also notably enhanced with the inclusion of HPMC. Improved adhesion ensures that tiles and other materials have a stronger bond, reducing the risk of dislodgement or cracking over time. This is particularly relevant in tiling applications, where the strength of the bond can significantly influence the longevity of the installation. The increased adhesion offered by HPMC-modified mortar contributes to overall structural integrity, making it a popular choice for both residential and commercial projects.

hpmc for mortar

In the pharmaceutical sector, HPMC is widely used as a drug delivery agent. Its ability to form gels and control the release of active pharmaceutical ingredients (APIs) makes it an invaluable excipient in various formulations, including tablets, capsules, and topical creams. HPMC is particularly favored for its safety profile, as it is non-toxic and has been approved by various health authorities worldwide for use in drug products. Additionally, it helps in achieving sustained-release mechanisms, ensuring that medications are delivered over an extended period, improving patient compliance and treatment effectiveness.

hpmc powder

Key Considerations When Choosing a Supplier