Links:

-

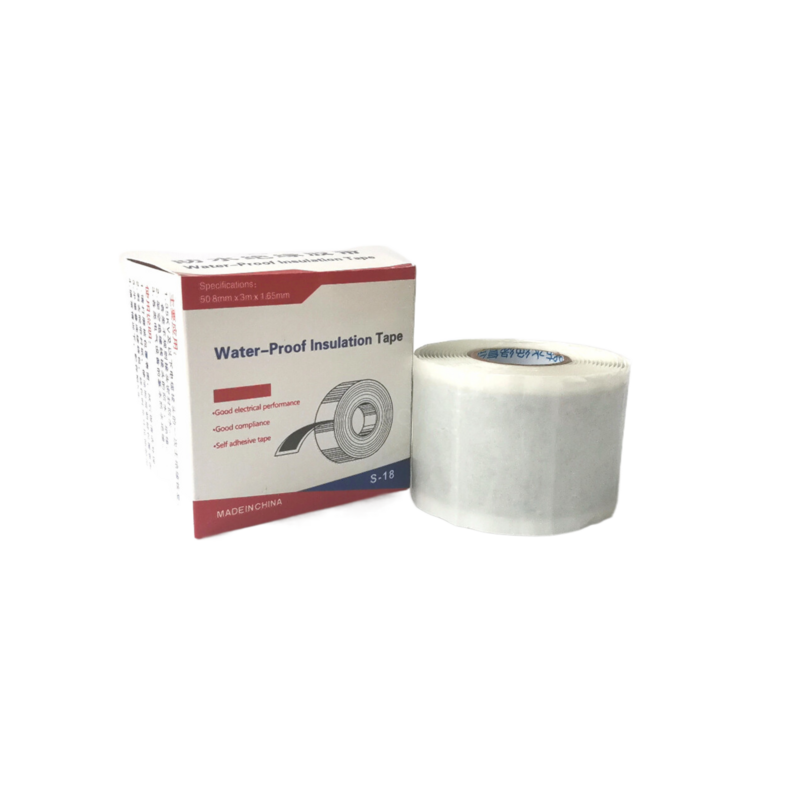

Moreover, the tape embodies compliance with health and safety regulations

- Brown: Brown tape signifies “high voltage, phase A.”

- Chemical Resistance – Polyester offers good resistance to many chemicals, solvents, and oils. It can withstand exposure to a wide range of chemicals without significant degradation, making it suitable for applications in harsh chemical environments.

- Automotive. Furthermore, self fusing rubber tape is easy to use. Simply stretch the tape and wrap it around the object you wish to bond. Press the ends together to secure the bond, and the tape will begin fusing to itself within minutes. It requires no special tools or expertise, making it accessible to anyone needing a quick and reliable solution. Applying fireproof tape for drywall is a relatively simple process, but it's important to follow the manufacturer's instructions carefully to ensure optimal results. Here are the basic steps to follow Different Types of Blue Tape Electrical

The Versatility of Black PVC Electrical Tape

Color: Black

In larger electrical systems, where a main circuit breaker might control several sub-panels, it’s important to choose high quality electrical enclosures for all junction boxes in the system. It’s also crucial to check the NEMA and IP ratings of a breaker box, particularly if it’s being installed as part of an outdoor electrical system.

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications 3m self vulcanizing tape. Rubber tape for leaks is an essential tool for any homeowner or DIY enthusiast. Whether you have a small leak in your roof, a broken pipe in your bathroom, or a crack in your window seal, rubber tape can provide a quick and effective solution to prevent further damage. In conclusion, insulation cotton tape, with its unique blend of traditional materials and modern functionality, has become an indispensable tool across various sectors. Its versatility, durability, and insulation capabilities make it a go-to solution for insulation needs, whether it's protecting electrical wires, enhancing HVAC efficiency, supporting athletes, or caring for patients. Its continued evolution and application in new areas demonstrate the enduring value of this humble yet highly effective material in our modern world.

3m self vulcanizing tape. Rubber tape for leaks is an essential tool for any homeowner or DIY enthusiast. Whether you have a small leak in your roof, a broken pipe in your bathroom, or a crack in your window seal, rubber tape can provide a quick and effective solution to prevent further damage. In conclusion, insulation cotton tape, with its unique blend of traditional materials and modern functionality, has become an indispensable tool across various sectors. Its versatility, durability, and insulation capabilities make it a go-to solution for insulation needs, whether it's protecting electrical wires, enhancing HVAC efficiency, supporting athletes, or caring for patients. Its continued evolution and application in new areas demonstrate the enduring value of this humble yet highly effective material in our modern world. 4. Versatility Besides electrical insulation, high voltage self-fusing rubber tape has numerous applications, ranging from automotive repairs to plumbing and HVAC systems. Its ability to conform to various shapes and surfaces makes it an invaluable tool for both electrical and mechanical repairs.

high voltage self fusing rubber tape

In conclusion, insulation cotton tape, with its unique blend of traditional materials and modern functionality, has become an indispensable tool across various sectors. Its versatility, durability, and insulation capabilities make it a go-to solution for insulation needs, whether it's protecting electrical wires, enhancing HVAC efficiency, supporting athletes, or caring for patients. Its continued evolution and application in new areas demonstrate the enduring value of this humble yet highly effective material in our modern world. The Revolutionary Role of Self- Annealing Tape in Modern Technology

self vulcanizing tape. In conclusion, black flex seal tape is much more than just a simple roll of adhesive. It combines flexibility, durability, and ease of use to become a staple in many toolboxes and workshops. Its versatility extends to countless projects, making it an affordable and efficient solution for a wide range of sealing needs. With black flex seal tape, you're not just buying a product; you're investing in peace of mind, knowing that your repairs are strong, secure, and enduring.

As described in the article “How Polyimide Tapes are Made“, tapes are composed of two distinct layers, each of which is critical to the properties of the final product. The first layer is the backing material, and whether this is polyimide film (the generic verison of DuPont’s Kapton), polyvinyl chloride (PVC), Polyethylene terephthalate (PET), or some other plastic, cloth or paper material, this layer is selected to provide half of the tape’s final properties. The other half is determined by the adhesive layer applied to this backing layer.

Advantages of PVC Electrical InsulationProperly taping a motor connection

The rubber adhesive used in Polyethylene Rubber Tape offers several advantages that contribute to its performance and effectiveness.

Moreover, the 4 x 5 size is perfectly designed for a range of tasks In addition to its practical uses, the Flex Tape Black 8 x 5 also has a sleek and professional appearance. Its black color and sleek design make it a great addition to any workspace or toolbox, adding a touch of style and sophistication. It is also easy to clean and maintain, ensuring that it stays looking like new for years to come. Moreover, automotive fabric tapes are known for their durability and resistance to harsh environmental conditions Furthermore, black PVC tape has a wide range of applications beyond electrical work. It can be used for crafting, automotive repairs, plumbing, and even for general household tasks. Its versatility and durability make it a go-to solution for countless projects and repairs.Our silicone repair tape is available from £5.15 per roll.

Vulcanizing Tape is a type of self-fusing rubber tape that adheres to itself without the need for an adhesive. This unique property allows the tape to create a watertight and airtight seal when wrapped around an object. It's often utilized for electrical insulation, plumbing repairs, and automotive applications. The tape is resistant to extreme temperatures, UV exposure, and various chemicals, making it exceptionally durable in diverse environments.