Links:

-

In conclusion, replacing a chain link fence is an intricate dance of functionality and form. It requires an eye for detail, an understanding of materials, and a respect for the structure’s role in both security and aesthetics. When done right, it revitalizes not just a perimeter, but possibly an entire outlook on one of the most underappreciated aspects of our built environment. However, it's essential to consider the impact on ride comfort

5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality. One of the main benefits of using a tomato cage is that it helps to keep the plant off the ground, which can prevent rotting and disease. When tomato plants are left to sprawl on the ground, they are more susceptible to pests and diseases that can damage the fruit and reduce yields. By using a tomato cage, you can lift the plant off the ground and allow for better air circulation, reducing the risk of disease and promoting healthier growth. 3. Ensure that the walls are properly prepared before installing the ties, including cleaning the surfaces and removing any debris or obstructions. In modern building practices, brick ties play a crucial role not just in residential homes but also in commercial buildings and other structures where cavity walls are utilized. They contribute to energy efficiency by helping to maintain the thermal barrier created by the cavity. Moreover, they provide a level of fire resistance and can aid in noise reduction between adjacent rooms or units. Suppliers, too, hold a considerable h% stake. Their ability to provide quality inputs at competitive prices can significantly affect a company's bottom line. Furthermore, the local community, often overlooked, is a vital h% stakeholder. A company's social responsibility initiatives and its impact on the community can influence its license to operate and public perception. Spiral torsion springs are typically made from materials such as stainless steel, carbon steel, or titanium, which gives them a high level of durability and resistance to corrosion. This makes them suitable for use in a wide range of environments, including those with high levels of moisture or temperature fluctuations. Firstly, the material composition plays a crucial role in determining the price. Chicken wire is typically made of galvanized steel, which is resistant to rust and corrosion, making it suitable for outdoor use. The quality of the steel used can greatly affect the price. Higher grade steel, while more durable, will naturally come at a higher cost than lower grade alternatives.

5 inch coil springs. While these springs do provide a firmer ride, modern coil spring design mitigates harshness, often incorporating progressive rates that are less stiff under light loads. This means that for daily driving, the 5% 20-inch coil springs can still deliver a comfortable ride, striking a balance between performance and practicality. One of the main benefits of using a tomato cage is that it helps to keep the plant off the ground, which can prevent rotting and disease. When tomato plants are left to sprawl on the ground, they are more susceptible to pests and diseases that can damage the fruit and reduce yields. By using a tomato cage, you can lift the plant off the ground and allow for better air circulation, reducing the risk of disease and promoting healthier growth. 3. Ensure that the walls are properly prepared before installing the ties, including cleaning the surfaces and removing any debris or obstructions. In modern building practices, brick ties play a crucial role not just in residential homes but also in commercial buildings and other structures where cavity walls are utilized. They contribute to energy efficiency by helping to maintain the thermal barrier created by the cavity. Moreover, they provide a level of fire resistance and can aid in noise reduction between adjacent rooms or units. Suppliers, too, hold a considerable h% stake. Their ability to provide quality inputs at competitive prices can significantly affect a company's bottom line. Furthermore, the local community, often overlooked, is a vital h% stakeholder. A company's social responsibility initiatives and its impact on the community can influence its license to operate and public perception. Spiral torsion springs are typically made from materials such as stainless steel, carbon steel, or titanium, which gives them a high level of durability and resistance to corrosion. This makes them suitable for use in a wide range of environments, including those with high levels of moisture or temperature fluctuations. Firstly, the material composition plays a crucial role in determining the price. Chicken wire is typically made of galvanized steel, which is resistant to rust and corrosion, making it suitable for outdoor use. The quality of the steel used can greatly affect the price. Higher grade steel, while more durable, will naturally come at a higher cost than lower grade alternatives.

Galvanized iron wire’s utility extends beyond just binding rebar and structural materials. It is also used in a range of other applications within the construction sector. For example, it can be utilized in the installation of scaffolding, providing a secure means of fastening various components. It is also employed in the construction of fences, where its durability ensures that the fencing remains intact and rust-free for many years. Furthermore, in masonry work, it can be used to tie bricks or blocks together, enhancing the overall stability of the structure.

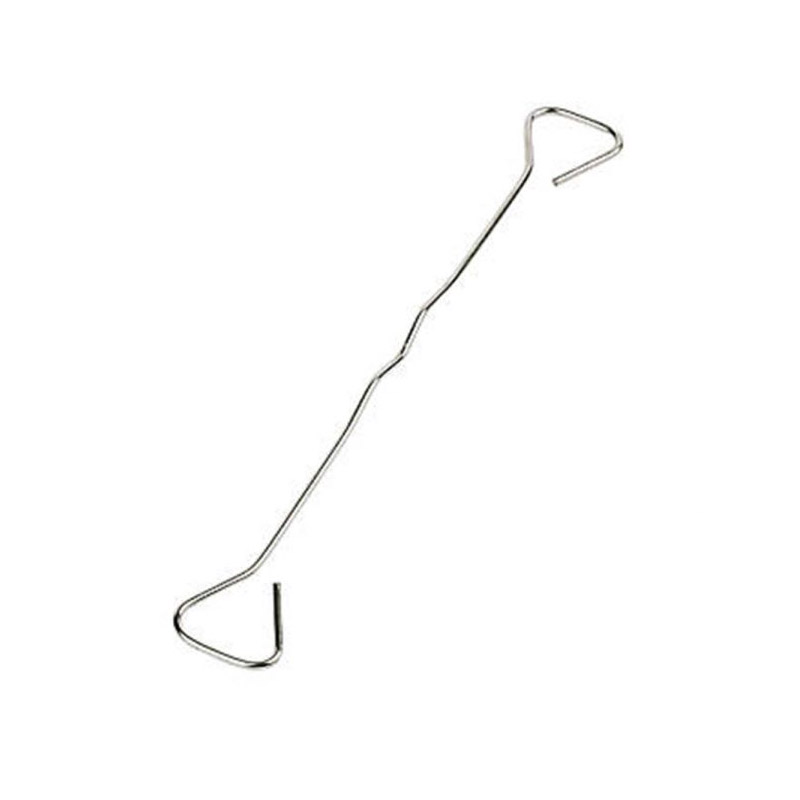

Wall Ties and Adjustable Brick Ties

Black Annealed Wire: Internal Support for Cables

Stake wire fencing is a popular choice for homeowners looking to secure their property while maintaining a budget-friendly option. This type of fencing is made from lightweight materials such as steel wire that are easy to install and can be a cost-effective alternative to traditional wood or vinyl fencing. Amaryllis plant stakes are an essential gardening tool that provide support and stability to these beautiful and popular flowers. These stakes are designed to be used with amaryllis plants, which are known for their large, showy blooms that add a touch of elegance to any garden or home. However, it's essential to consider the quality of the material when selecting welded wire mesh sheets. Factors such as the grade of steel, the welding process, and the finish can significantly influence the product's performance and longevity. Regular maintenance, including cleaning and inspections, can further extend its service life. In conclusion, spring helical extension is more than just a simple mechanical concept; it is a sophisticated engineering principle that underpins numerous technological advancements. Its understanding and application have significantly influenced the design and functionality of countless devices, highlighting the profound impact of physics on our daily lives. As technology continues to evolve, the significance of spring helical extension will likely remain steadfast, serving as a cornerstone in mechanical engineering. Moreover, the versatility of welded wire mesh extends to the manufacturing of furniture, automotive components, and even artistic installations. The mesh can be easily cut, shaped, and bent to suit a myriad of designs and purposes. Installing a Tomato Cage A Step-by-Step Guide Overall, black chain link fencing is an excellent choice for property owners looking for a cost-effective, durable, and versatile fencing solution. Its affordability, durability, low maintenance, and modern aesthetic make it a top choice for securing residential and commercial properties alike. Whether you need to secure a backyard, commercial property, or industrial site, black chain link fencing is a practical and stylish option to consider. The double-sided sign holder, with its dual façades, represented more than just a tool for displaying messages. It was a testament to the human need for connection and understanding in a world that often seemed to prioritize division and individualism. Its very design, allowing for two distinct messages to be presented simultaneously, reflected the complexities of human nature and the importance of multiple perspectives. 4. Belleville washers These springs are conical-shaped and provide a nonlinear restoring force. They are commonly used in pressure gauges, clamps, and other applications where a high load capacity and a wide range of deflections are required. 6 Gauge Size The gauge size of welded wire refers to its diameter. Thicker wires are generally stronger but also more expensive than thinner wires. When selecting a gauge size, consider the specific requirements of your project, such as the load it will bear or the space constraints. Expansion wall ties play a crucial role in ensuring the stability and structural integrity of buildings. These ties are designed to securely connect two parallel walls and accommodate any thermal movements or expansion and contraction that may occur. Expansion wall ties are commonly used in construction projects to prevent cracks and damage caused by the natural movements of a building. The Utility Extension Spring A Vital Component in Modern Engineering When shopping for concrete mesh wire, it's important to choose a reputable supplier who offers high-quality products at competitive prices. Look for suppliers who offer a wide range of sizes and styles to suit your specific needs, as well as excellent customer service and support. With the right supplier on your side, you can enjoy all the benefits of concrete mesh wire without breaking the bank. 2. Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame

Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame Create a Frame If you're working on a larger piece, like a wedding centerpiece or wreath, consider using thick floral wire to create a basic frame thick floral wire. This will provide structure and support as you fill in the gaps with flowers and foliage. 4. Regularly inspect the ties and walls for signs of damage or wear, and replace any ties that show signs of deterioration. The manufacturing sector also relies on galvanized wire

thick floral wire. This will provide structure and support as you fill in the gaps with flowers and foliage. 4. Regularly inspect the ties and walls for signs of damage or wear, and replace any ties that show signs of deterioration. The manufacturing sector also relies on galvanized wire galvanized wire for sale. In the production of wire ropes, springs, and various hardware items, galvanized wire offers a balance between strength, flexibility, and corrosion resistance. It's also a popular choice for electrical grounding and cable assemblies due to its conductivity properties. In addition to their aesthetic appeal, black wire panels are also extremely functional. They can be used in a variety of ways, from creating partitions in open-concept spaces to serving as decorative elements on walls or ceilings. Their sturdy construction means that they can support heavy objects, making them a practical choice for both decorative and practical applications. In addition to choosing the right type of tomato cage, it is also important to properly install and secure the cages in place. Make sure to place the cages around the plants early in the growing season, before the plants become too large and unwieldy. Secure the cages firmly in the ground to prevent them from toppling over in strong winds or heavy rains. 2. 소리의 벽판 경량 및 뛰어난 소음 흡수 성질 덕분에 리브 라스틱 스테인레스 Steel은 종종 소리 벽판을 만드는 데 사용됩니다. Another popular option for cattle field fencing is electric fencing. Electric fencing works by delivering a mild electric shock to any animal that comes into contact with it. While this may sound harsh, the shock is not harmful and serves as a deterrent to keep cattle from pushing against the fence or attempting to escape. Electric fencing is also highly effective at keeping out predators such as coyotes and wolves

galvanized wire for sale. In the production of wire ropes, springs, and various hardware items, galvanized wire offers a balance between strength, flexibility, and corrosion resistance. It's also a popular choice for electrical grounding and cable assemblies due to its conductivity properties. In addition to their aesthetic appeal, black wire panels are also extremely functional. They can be used in a variety of ways, from creating partitions in open-concept spaces to serving as decorative elements on walls or ceilings. Their sturdy construction means that they can support heavy objects, making them a practical choice for both decorative and practical applications. In addition to choosing the right type of tomato cage, it is also important to properly install and secure the cages in place. Make sure to place the cages around the plants early in the growing season, before the plants become too large and unwieldy. Secure the cages firmly in the ground to prevent them from toppling over in strong winds or heavy rains. 2. 소리의 벽판 경량 및 뛰어난 소음 흡수 성질 덕분에 리브 라스틱 스테인레스 Steel은 종종 소리 벽판을 만드는 데 사용됩니다. Another popular option for cattle field fencing is electric fencing. Electric fencing works by delivering a mild electric shock to any animal that comes into contact with it. While this may sound harsh, the shock is not harmful and serves as a deterrent to keep cattle from pushing against the fence or attempting to escape. Electric fencing is also highly effective at keeping out predators such as coyotes and wolves

cattle field fence. PVC Coated Galvanized Wire A Versatile Material for Various Applications Setting up a chicken wire tomato cage is also a breeze. Simply unroll the cage and place it over your tomato plants, making sure it is securely in place. As the plants grow, you can gently guide them through the openings in the cage, allowing them to reach their full potential. Another type of snake spacer is the metal mesh spacer. This type of spacer is often used in larger enclosures or in situations where extra support is needed. The metal mesh spacer provides a sturdy barrier between the lid and the enclosure, ensuring that the lid stays secure and the snake stays safe

snake spacers. Wall ties, as their name suggests, are metal fixtures used to connect internal and external brick or block walls, ensuring they function as a single, cohesive unit. They prevent the walls from moving independently and mitigate the risk of shearing or cracking, particularly in areas prone to harsh weather conditions or seismic activity. Aluminum chain link fences are also very affordable compared to other types of fencing materials. The cost of aluminum is typically lower than materials such as wrought iron or steel, making it a cost-effective choice for property owners on a budget. Additionally, the installation process for aluminum chain link fences is relatively simple and straightforward, further reducing the overall cost of the project. Benefits of Metal Staking However, it's essential to consider the impact on ride comfort

Concrete formwork accessories play a vital role in the construction industry, serving as the backbone of structural integrity and precision in concrete pouring operations. These specialized tools and equipment ensure that concrete is cast into the desired shape and size, facilitating the creation of robust and durable structures. The Significance of Horizontal Joint Reinforcement in Masonry Construction

Concrete formwork accessories play a vital role in the construction industry, serving as the backbone of structural integrity and precision in concrete pouring operations. These specialized tools and equipment ensure that concrete is cast into the desired shape and size, facilitating the creation of robust and durable structures. The Significance of Horizontal Joint Reinforcement in Masonry Construction Stainless steel mesh has become a popular choice for a wide range of applications due to its durability, strength, and corrosion resistance. As a result, the demand for stainless steel mesh suppliers has been steadily increasing. These suppliers play a crucial role in providing high-quality stainless steel mesh products to various industries, including construction, automotive, food processing, and more.

Improve seismic performance: high-quality and suitable connectors help improve the seismic resistance of walls in natural disasters such as earthquakes and reduce the degree of damage.

Despite their seemingly humble role, steel-to-masonry ties have a significant impact on the safety, durability, and energy efficiency of a building. They contribute to fire resistance, sound insulation, and even thermal performance, making them a key element in green construction practices. One of the most significant applications of stainless steel wire mesh is in the field of filtration. Its unique properties, including high strength, excellent corrosion resistance, and precise aperture sizes, make it an ideal choice for various types of filters, such as air, water, oil, and gas filters. Stainless steel wire mesh filters effectively remove impurities, particles, and debris from fluids, ensuring their cleanliness and quality. In conclusion, wall ties for cavity walls are more than just connectors; they are integral components that ensure the robustness and resilience of a building. Their role in structural integrity cannot be overstated, making them a critical aspect of construction planning and maintenance. Understanding their function and the potential risks associated with their deterioration is vital for both builders and homeowners alike. After all, it is often the unseen elements, like wall ties, that truly hold a building together. Furthermore, the finish or coating of the mesh is another pricing factor. Galvanized or PVC-coated meshes provide corrosion resistance, enhancing durability but also increasing the price. Special coatings for specific applications, such as those resistant to chemicals or extreme weather conditions, can further escalate the cost. 2. Measure and mark Use a tape measure to determine the location of the cavity wall ties. Mark the positions on the inner and outer walls using a pencil or chalk. Make sure to allow enough space for the ties to accommodate any potential movement. The importance of masonry tie-backs is not just limited to their function as a physical support. They also contribute significantly to the overall aesthetics of the structure. By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work

By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work By preventing bulging or cracking, they maintain the straightness and alignment of walls, preserving the visual appeal of the masonry work masonry tie backs.

masonry tie backs.