Current location:

Links:

-

In conclusion, the price of 6305 ZZ bearings is a complex interplay of material quality, manufacturing processes, brand reputation, market forces, and distribution factors. While a lower price might seem attractive, it's crucial to consider the overall value proposition - reliability, durability, and potential long-term savings. When investing in these bearings, it's advisable to strike a balance between cost and quality to ensure optimal performance and efficiency in your machinery. 6302 Bearings Exceptional Performance and Specifications Social Unrest The 6210 C3 bearing is a high-performance and reliable bearing that offers numerous benefits for various applications. Its deep groove design, durable construction, and high load capacity make it an excellent choice for engineers and manufacturers looking for a reliable and efficient bearing solution. 3. Inspect the bearing for damage Look for signs of wear, corrosion, or other forms of damage that may be causing the problem.

- Load-Carrying Capacity: Many manufacturers and suppliers offer a range of 22218 bearings at different price points to cater to the diverse needs of customers. Some may offer bulk discounts for large orders, while others may provide customized solutions or value-added services to justify a higher price tag. It's essential for buyers to do their due diligence, compare options, and consider factors beyond just the price when choosing a 22218 bearing for their applications. Conclusion One of the key advantages of double row thrust ball bearings lies in their versatility. They are widely employed in industries such as automotive, aerospace, petrochemical, and heavy machinery, where they facilitate smooth linear movement and support in applications involving pumps, compressors, turbines, and conveyors. Their ability to withstand high axial loads while maintaining a low coefficient of friction makes them ideal for these demanding conditions. The material composition of the NU 316 bearing is another factor contributing to its durability and resilience

The Elegance of Single Roller Bearings in Modern Mechanics

Thrust Bearings:

In addition to their high performance, our angular contact ball bearings are also known for their durability and reliability. They are manufactured from high-quality materials and undergo rigorous testing to ensure they meet the highest standards of quality and performance. * Cage material Steel or brass Introduction In conclusion, cylindrical roller bearings are more than just mechanical components; they are integral to the seamless functioning of many industries. From automotive to aerospace, from power generation to construction, their impact is far-reaching. They embody a perfect blend of strength, efficiency, and versatility, making them a staple in modern engineering. As technology continues to evolve, so will the design and application of cylindrical roller bearings, further enhancing their performance and expanding their scope in the global industrial landscape. Moreover, cylindrical roller bearings find application in the wind energy sector, where they are installed in the main shafts and gearboxes of wind turbines. The ability to manage high loads and withstand severe weather conditions is crucial in this context, as it contributes to the reliability and longevity of the turbine. In the rapidly evolving landscape of the 21st century, technology has emerged as a driving force that is fundamentally reshaping our world. From the way we communicate and conduct business to the way we access information and live our daily lives, technology has become an integral part of our existence. This transformation is particularly evident in the realm of remote sensing and location-based services (RLS), which have revolutionized the way we interact with our environment and each other. On the other hand, angular contact bearings feature raceways that are designed to carry primarily axial loads in one direction. These bearings have a contact angle between the inner and outer races, which allows them to support both axial and radial loads simultaneously. Angular contact bearings are commonly used in applications where there are high-speed or high-precision requirements, such as in machine tools, robotics, and aerospace equipment. The term tapered refers to the gradual decrease in diameter from one end to the other. In the context of wheels, this design translates into a cone-like shape, where the hub, the inner part that connects to the axle, is larger than the outer rim. This geometry offers a multitude of advantages that have made it a staple in engineering. On the other hand, the increased cost of bearings can also be passed down to consumers through higher equipment prices

* Cage material Steel or brass Introduction In conclusion, cylindrical roller bearings are more than just mechanical components; they are integral to the seamless functioning of many industries. From automotive to aerospace, from power generation to construction, their impact is far-reaching. They embody a perfect blend of strength, efficiency, and versatility, making them a staple in modern engineering. As technology continues to evolve, so will the design and application of cylindrical roller bearings, further enhancing their performance and expanding their scope in the global industrial landscape. Moreover, cylindrical roller bearings find application in the wind energy sector, where they are installed in the main shafts and gearboxes of wind turbines. The ability to manage high loads and withstand severe weather conditions is crucial in this context, as it contributes to the reliability and longevity of the turbine. In the rapidly evolving landscape of the 21st century, technology has emerged as a driving force that is fundamentally reshaping our world. From the way we communicate and conduct business to the way we access information and live our daily lives, technology has become an integral part of our existence. This transformation is particularly evident in the realm of remote sensing and location-based services (RLS), which have revolutionized the way we interact with our environment and each other. On the other hand, angular contact bearings feature raceways that are designed to carry primarily axial loads in one direction. These bearings have a contact angle between the inner and outer races, which allows them to support both axial and radial loads simultaneously. Angular contact bearings are commonly used in applications where there are high-speed or high-precision requirements, such as in machine tools, robotics, and aerospace equipment. The term tapered refers to the gradual decrease in diameter from one end to the other. In the context of wheels, this design translates into a cone-like shape, where the hub, the inner part that connects to the axle, is larger than the outer rim. This geometry offers a multitude of advantages that have made it a staple in engineering. On the other hand, the increased cost of bearings can also be passed down to consumers through higher equipment prices 32312 bearing price. This can limit the adoption of new machinery and technologies, particularly in sectors where affordability is a key consideration. As a result, the industry may struggle to keep pace with technological advancements and remain competitive in the global market. On the other hand, larger thrust bearings are commonly employed in heavy-duty applications such as oil rigs, wind turbines, and industrial machinery. They can manage substantial axial loads and provide stability under immense stress, making them indispensable for these high-stress environments.

32312 bearing price. This can limit the adoption of new machinery and technologies, particularly in sectors where affordability is a key consideration. As a result, the industry may struggle to keep pace with technological advancements and remain competitive in the global market. On the other hand, larger thrust bearings are commonly employed in heavy-duty applications such as oil rigs, wind turbines, and industrial machinery. They can manage substantial axial loads and provide stability under immense stress, making them indispensable for these high-stress environments. - Ball Bearing: Ball bearings are primarily designed to support radial loads, with some variations capable of handling light axial loads. They are widely used in applications where smooth and efficient rotation is essential, such as in machinery, equipment, and automotive components.

In the intricate world of mechanical engineering and precision machinery, the 6210 ball bearing stands as an unsung hero, silently facilitating smooth operations and enhancing efficiency. This seemingly small component plays a colossal role in various industries, from automotive to aerospace, and even in everyday appliances. * Sealed design The 6310 RS bearing features a sealed design that prevents dirt and debris from entering the bearing, extending its life and maintaining performance. Another critical aspect is the preload applied to angular contact bearings High precision deep groove ball bearings are essential components in many mechanical systems, providing smooth rotation and reduced friction. These bearings are designed to withstand high speeds and heavy loads, making them ideal for use in a wide range of industrial applications. Another significant advantage of tapered roller bearings is their ability to withstand misalignment. The conical raceways allow the bearings to accommodate small amounts of misalignment, which can occur due to manufacturing tolerances or thermal expansion. This means that these bearings can be used in applications where precise alignment is not critical, further expanding their versatility. Conclusion In many industrial applications, such as machine tools, motors, and pumps, these bearings are indispensable. They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads

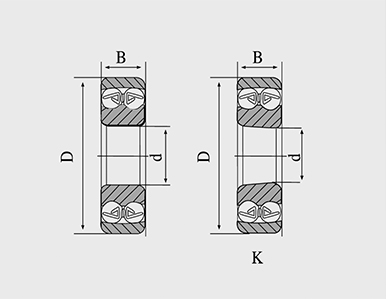

They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads They are commonly used in spindles, where they help maintain precise rotational accuracy while withstanding significant thrust loads axial angular contact ball bearing. In the automotive industry, they are employed in transmission systems and wheel hubs, where they manage the combined axial and radial forces effectively. 4. Plummer block bearings These bearings have a housing that provides additional support and alignment. The 51202 thrust bearing is not just another bearing; it is a testament to human ingenuity and the relentless pursuit of improvement. Designed to withstand substantial axial loads while minimizing friction and wear, this bearing is a cornerstone for modern machinery operating under high pressure and speed. Its unique structure allows it to manage extreme force applications that would degrade conventional bearings, extending the lifespan of critical equipment and reducing maintenance costs significantly. In terms of installation, double-row deep groove ball bearings are slightly more complex than single-row bearings due to their additional row of balls

axial angular contact ball bearing. In the automotive industry, they are employed in transmission systems and wheel hubs, where they manage the combined axial and radial forces effectively. 4. Plummer block bearings These bearings have a housing that provides additional support and alignment. The 51202 thrust bearing is not just another bearing; it is a testament to human ingenuity and the relentless pursuit of improvement. Designed to withstand substantial axial loads while minimizing friction and wear, this bearing is a cornerstone for modern machinery operating under high pressure and speed. Its unique structure allows it to manage extreme force applications that would degrade conventional bearings, extending the lifespan of critical equipment and reducing maintenance costs significantly. In terms of installation, double-row deep groove ball bearings are slightly more complex than single-row bearings due to their additional row of balls Double row thrust ball bearings, an integral part of numerous mechanical and engineering systems, play a pivotal role in facilitating linear motion and withstanding heavy axial loads. These specialized bearings, with their unique design and functionality, have become indispensable in various industries due to their efficiency and durability. The 62204 Bearing A Comprehensive Guide to Its Dimensions The application spectrum of the Nu312 bearing is wide and diverse

Double row thrust ball bearings, an integral part of numerous mechanical and engineering systems, play a pivotal role in facilitating linear motion and withstanding heavy axial loads. These specialized bearings, with their unique design and functionality, have become indispensable in various industries due to their efficiency and durability. The 62204 Bearing A Comprehensive Guide to Its Dimensions The application spectrum of the Nu312 bearing is wide and diverse nu312 bearing. It finds its use in industries ranging from automotive, mining, and construction to power generation and heavy machinery. In automotive engines, for instance, these bearings support the crankshaft, ensuring smooth rotation and minimizing friction. In industrial machinery, they help maintain consistent performance under heavy loads, contributing to overall productivity. The 6228 bearing also features a deep groove design, allowing it to accommodate not only radial loads but also a certain degree of axial loads in both directions The Impact of SL04 5022 on Society and the Environment Choosing Between Cylindrical Roller Bearings and Ball Bearings In conclusion, the 62305 bearing, with its specific dimensions of 25mm ID, 62mm OD, and 17mm width, offers a reliable solution for various applications. Its design, combined with the right tolerances and materials, makes it a versatile and dependable choice in the realm of bearings. Always consult manufacturer specifications and consider operating conditions when choosing the perfect 62305 bearing for your project. Deep groove ball bearings are essential components in various machinery and equipment, providing smooth and efficient rotation for the moving parts. One such example is the Timken 6203-2RSC3 deep groove ball bearing, which measures 17x40x12mm in dimensions. This particular bearing model is known for its high quality and durability, making it a popular choice among manufacturers and engineers. One of the key features of a taper roller bearing assembly is its tapered shape, which allows for even distribution of the load along the rollers. This design helps to reduce friction and wear on the bearings, enhancing their durability and longevity. The tapered shape also allows for precision placement and alignment of the rollers, ensuring smooth and consistent operation. Conclusion

nu312 bearing. It finds its use in industries ranging from automotive, mining, and construction to power generation and heavy machinery. In automotive engines, for instance, these bearings support the crankshaft, ensuring smooth rotation and minimizing friction. In industrial machinery, they help maintain consistent performance under heavy loads, contributing to overall productivity. The 6228 bearing also features a deep groove design, allowing it to accommodate not only radial loads but also a certain degree of axial loads in both directions The Impact of SL04 5022 on Society and the Environment Choosing Between Cylindrical Roller Bearings and Ball Bearings In conclusion, the 62305 bearing, with its specific dimensions of 25mm ID, 62mm OD, and 17mm width, offers a reliable solution for various applications. Its design, combined with the right tolerances and materials, makes it a versatile and dependable choice in the realm of bearings. Always consult manufacturer specifications and consider operating conditions when choosing the perfect 62305 bearing for your project. Deep groove ball bearings are essential components in various machinery and equipment, providing smooth and efficient rotation for the moving parts. One such example is the Timken 6203-2RSC3 deep groove ball bearing, which measures 17x40x12mm in dimensions. This particular bearing model is known for its high quality and durability, making it a popular choice among manufacturers and engineers. One of the key features of a taper roller bearing assembly is its tapered shape, which allows for even distribution of the load along the rollers. This design helps to reduce friction and wear on the bearings, enhancing their durability and longevity. The tapered shape also allows for precision placement and alignment of the rollers, ensuring smooth and consistent operation. Conclusion - Thrust bearings, on the other hand, are designed to support axial loads within the engine or machinery. In an engine, thrust bearings are typically located at the end of the crankshaft to counteract the axial forces generated by the engine's operation. They are responsible for maintaining the axial position of the crankshaft and preventing it from moving forward or backward.

1. Single Row Cylindrical Roller Bearings2. Speed The bearing's maximum speed depends on its size and design. Larger bearings can handle higher speeds than smaller ones. Consult the manufacturer's data sheet for the maximum speed rating for your desired bearing size.