Links:

-

Don't forget to inquire about after-sales services such as installation assistance and warranty coverage. A good supplier should stand behind their products and offer support throughout the process. The integration of the Video Assistant Referee (VAR) system into football has been a subject of intense debate among players, coaches, and fans alike. With the tagline VAR for Justice, the technology aims to enhance fairness and accuracy in decision-making during matches. However, its implementation has not been without controversy, leading many to question its true impact on the beautiful game.

- Aluminium office partition

- Standard steel fences bend under less pressure, more easily damaged.

- Long lasting 2. Reduced friction The roller wheels reduce friction between the screen door and the frame, making it easier to glide the door open and closed. This not only makes the process more convenient but also extends the life of the screen door. Proper maintenance and care of the sliding wheels are essential to ensure the longevity of the door system. Regular cleaning and lubrication of the wheels will help prevent wear and tear, ensuring smooth operation for years to come. It is also important to inspect the wheels periodically for any signs of damage or wear and replace them if necessary to avoid any issues with the door's functionality. Before installing roller wheels on your screen door, it is important to ensure that the door is in good condition and free from any damage. Here are the steps to follow

In conclusion, stainless steel front door pull handles blend beauty with functionality, offering homeowners a stylish, durable, and low-maintenance option to enhance their entryway. Their ability to withstand the test of time, both in terms of style and physical endurance, makes them a smart investment for anyone looking to upgrade their home's curb appeal. By opting for stainless steel handles, you not only choose a product that is easy on the eyes but also one that promises long-lasting performance, ensuring your entrance remains as elegant and inviting as the day you installed them. Aesthetically, cast iron offers a unique texture and patina that only improves with age Overall, aluminum glazing bead is a superior choice for window and door construction due to its durability, versatility, and energy efficiency. Its ability to withstand harsh conditions, low maintenance requirements, and aesthetic appeal make it a popular material in the construction industry. Whether for residential or commercial applications, aluminum glazing bead is a reliable and cost-effective solution for window and door framing. However, the environmental benefits of cast iron cannot be overlooked. Its recyclability is a testament to its sustainability. Old, discarded cast iron products can be melted down and reused, reducing waste and conserving resources. Steel vs Iron A Comparative Analysis of Strength

Plastic taps are renowned for their lightweight nature and resistance to corrosion. Often made from materials such as PVC, nylon, or polypropylene, these taps are ideal for applications where exposure to water, chemicals, or harsh environments is a concern. Their corrosion-resistant properties make them particularly popular in agricultural settings and industries dealing with acids or bases.

Sliding mirror doors, equipped with their roller systems, are a popular choice for modern interior design due to their sleek aesthetics and space-saving functionality. These doors, often utilized in bedrooms for wardrobe entrances or in bathrooms for compact spaces, consist of large mirrors mounted on a sliding track system, allowing them to move effortlessly along the wall.

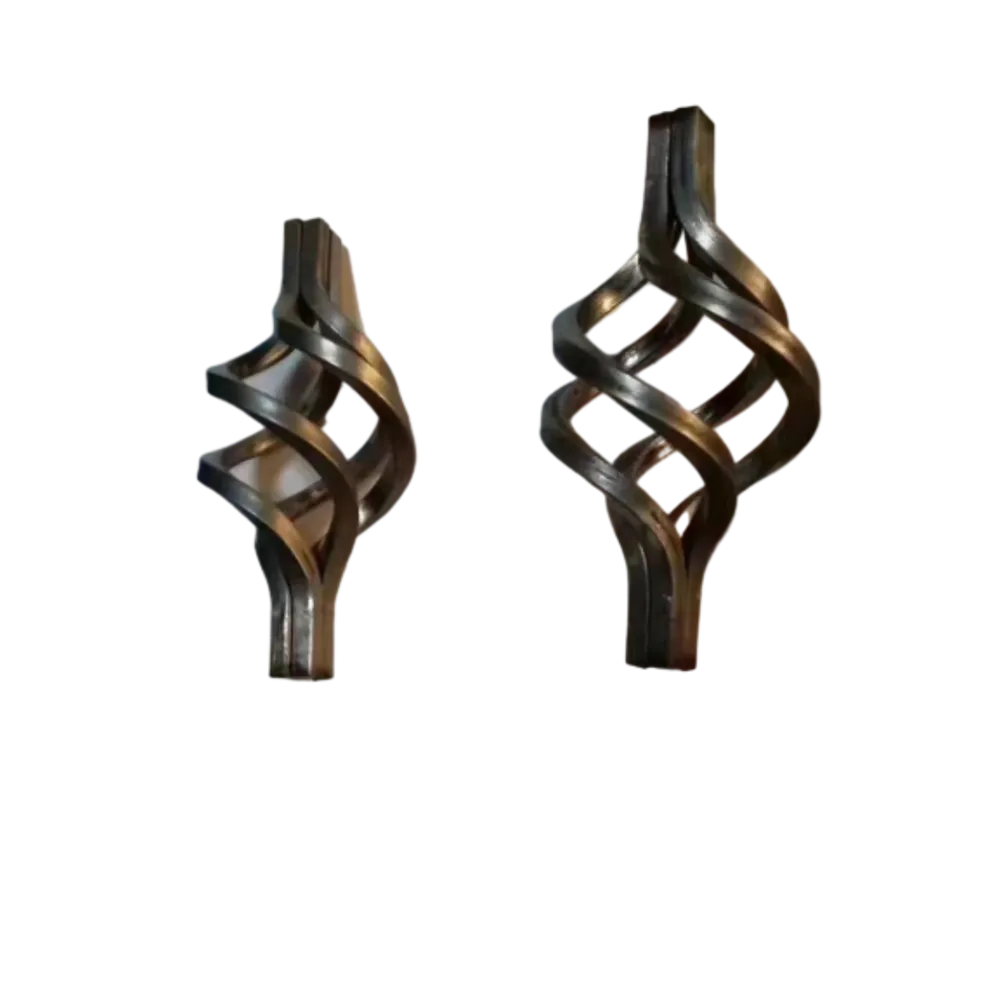

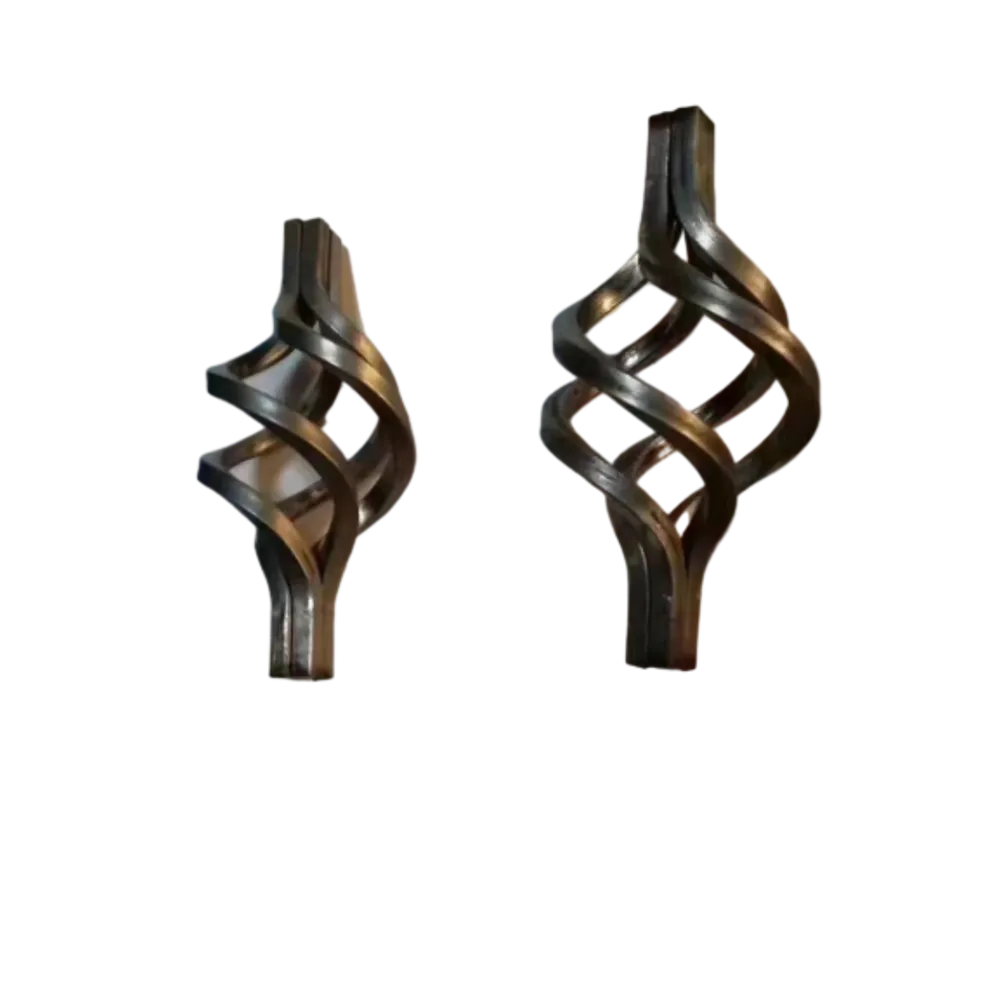

Wrought Iron & Ornamental Iron

They also provide better aesthetics and longevity compared to traditionally used materials like PVC.

The Silent Guardians An Ode to Sliding Door Floor Rollers The Significance of Aluminium Windows and Their Wheels A Modern Architectural MarvelIn the realm of modern architecture and construction, the choice of materials plays a pivotal role in ensuring energy efficiency, durability, and aesthetic appeal. One of the increasingly popular options for high-performance window and door systems is the thermal break aluminium profile. This technology not only offers robust structural integrity but also enhances energy efficiency, making it an ideal choice for contemporary buildings.

Perhaps most importantly, the door trolley serves as a statement piece on the importance of efficient use of space. It challenges us to reconsider wasted areas in our homes and transform them into functional segments that add value to our daily lives. By doing so, it encourages a mindset shift towards optimization and creativity in home management. In conclusion, a window profile is a comprehensive description of a window's characteristics, encompassing measurements, materials, design features, and functionality. By understanding the details of a window profile, homeowners can make informed decisions when selecting windows for their home. Whether choosing a traditional wooden window or a modern vinyl option, the window profile provides essential information to ensure the right fit for every home. Both the cosulet and the bulb share a common thread - they bring comfort and convenience. While the cosulet offers physical warmth, the bulb illuminates our surroundings, fostering productivity, safety, and ambiance. They are silent companions in our daily routines, often taken for granted but always ready to serve.

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments sliding door roller replacement inc.

sliding door roller replacement inc. Steel door pull handles require minimal maintenance compared to other materials. A simple wipe down with a damp cloth is usually sufficient to keep them looking new. Unlike wood, which may need periodic refinishing, or plastic, which can discolor over time, steel handles can withstand the test of time with little upkeep. Their resistance to rust and tarnishing, particularly when finished properly, ensures longevity and an appealing appearance.

Types of Iron fence casting

The Multifaceted Benefits of a Stainless Steel Box with Lock

Another important element of a window profile is the materials used in its construction. Windows can be made from a variety of materials, such as wood, vinyl, aluminum, or fiberglass. Each material has its own set of benefits and drawbacks, including durability, energy efficiency, and maintenance requirements. The choice of material will impact the overall performance and appearance of the window.

True wrought iron fences are hand-shaped by blacksmiths or master craftsmen. They take time to produce and are usually custom created as needed, made to order.