Current location:

Links:

- Containment of Lubrication: The deep groove in a single row deep groove ball bearing provides space for lubricant, such as grease or oil, which helps to reduce friction, dissipate heat, and protect the bearing from wear and corrosion. Proper lubrication is essential for the smooth operation and longevity of the bearing. When it comes to purchasing bearings, one of the key factors to consider is the price. The 30207 bearing is a popular choice for many industrial applications, due to its durability and efficiency. However, the price of this particular bearing can vary depending on a number of factors. The inner diameter of the bearing is perhaps the most critical dimension, as it directly affects how securely the bearing will fit around the shaft. If the inner diameter is too large, the bearing may not provide adequate support, leading to increased wear and potential failure. Conversely, if the inner diameter is too small, the bearing may be difficult to install or cause excessive heat and damage due to tight clearances. Another significant advantage of the LM67010 bearing is its low friction coefficient

Another benefit of deep groove ball bearings is their durability In terms of maintenance, taper roller bearings require regular lubrication to reduce friction and prevent wear. They are typically lubricated with oil or grease, depending on the specific application and operating conditions. It's also important to regularly inspect them for signs of wear, damage, or excessive noise, as these can indicate potential issues that need addressing. Applications of High Temperature Bearings * Aerospace Bearings used in aircraft engines, landing gear, and other critical systems must be able to withstand extreme temperatures and conditions. 1. Load Capacity Conical roller bearings have a high load capacity due to their unique design. The conical rollers are angled, which allows them to support both radial and axial loads simultaneously. This results in higher load carrying capacity compared to other types of bearings like ball bearings or cylindrical roller bearings. Understanding the Dimensions of a 16003 Bearing A Comprehensive Guide Taper roller bearings are a type of rolling element bearing that is widely used in various industries due to its unique design and performance characteristics. These bearings consist of an inner ring, an outer ring, tapered rollers, and a cage that holds the rollers in place. The tapered shape of the rollers allows them to accommodate misalignment and absorb shock loads, making them particularly suitable for applications where these factors are present. 4. Lubrication These bearings are designed to operate effectively with a variety of lubricants, including grease and oil. Proper lubrication is crucial for maintaining the longevity and performance of the bearings, and the AN2002-series bearings are no exception. 1. High Load Capacity The 51213 bearing is designed with a large contact area and a robust design, which enables it to withstand high loads and (torsional moments). The 6203Z bearing also features a double sealed design, which helps to keep out contaminants and moisture that can cause damage to the bearing over time. This design also helps to prevent the loss of lubricant, ensuring that the bearing remains properly lubricated and performs at its best. The versatility of the 6309 C3 bearing makes it suitable for a wide range of applications across various industries

6309 c3 bearing dimensions. It is commonly used in conveyor systems, pumps, fans, and other machinery that require reliable and efficient rotation. In the automotive industry, these bearings are used in engine components, transmission systems, and suspension systems. They are also found in industrial machinery, such as lathes, grinders, and presses. The Ultimate Guide to the AN2002-Series Single-Row Deep Groove Ball Bearings In addition to aiding in the selection process, the taper bearing ID and OD chart can also be a valuable resource for troubleshooting and maintenance

6309 c3 bearing dimensions. It is commonly used in conveyor systems, pumps, fans, and other machinery that require reliable and efficient rotation. In the automotive industry, these bearings are used in engine components, transmission systems, and suspension systems. They are also found in industrial machinery, such as lathes, grinders, and presses. The Ultimate Guide to the AN2002-Series Single-Row Deep Groove Ball Bearings In addition to aiding in the selection process, the taper bearing ID and OD chart can also be a valuable resource for troubleshooting and maintenance

taper bearing id od chart. By referencing the chart, technicians can quickly identify the correct replacement bearing for a faulty or worn-out component. This can help minimize downtime and keep the system running smoothly. Overall, cylindrical thrust bearings play a vital role in the smooth and efficient operation of mechanical systems, providing support and stability for rotating shafts while minimizing friction and wear. With their high load-carrying capacity, excellent alignment capabilities, and versatility, these bearings are essential components in a wide range of industrial applications. In the medical field, where accuracy and reliability are paramount, SRDG ball bearings find application in surgical instruments, diagnostic machines, and prosthetics. Their precise movement and low noise characteristics contribute significantly to the overall performance of these devices. Overall, the best tapered roller bearings are a top choice for industries seeking high-performance bearings that can handle heavy loads, high speeds, and demanding operating conditions. With their superior design, quality materials, and excellent performance, these bearings provide a reliable and cost-effective solution for a wide range of applications. Whether used in automotive, aerospace, construction, or other industries, the best tapered roller bearings deliver consistent performance and long-lasting durability. In addition to quality, the brand of the bearing can also affect the price. Established brands with a reputation for quality and reliability may charge a premium for their bearings, while lesser-known brands may offer lower prices to attract customers. It is important for buyers to consider the reputation of the brand and read reviews from other customers to ensure they are purchasing a reliable product

22324 bearing price. Thrust ball bearings are a type of rolling element bearing that is designed to accommodate both radial and axial loads. These bearings consist of a shaft washer, a housing washer, and a number of balls that roll between the two washers. The housing for these bearings is an essential component as it provides support and protection for the bearing and its components. In this article, we will discuss the importance of the thrust ball bearing housing and how it affects the performance of the bearing. 3. Quality Concerns Some low-price bearings may be manufactured using substandard materials or inferior processes, which can compromise their performance and safety in critical applications. Another benefit of single deep groove ball bearings is their versatility in terms of applications. They are commonly used in electric motors, pumps, gearboxes, and conveyor systems, among other machinery. The single row design allows for compact and lightweight construction, making them ideal for space-constrained installations. Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements

Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements

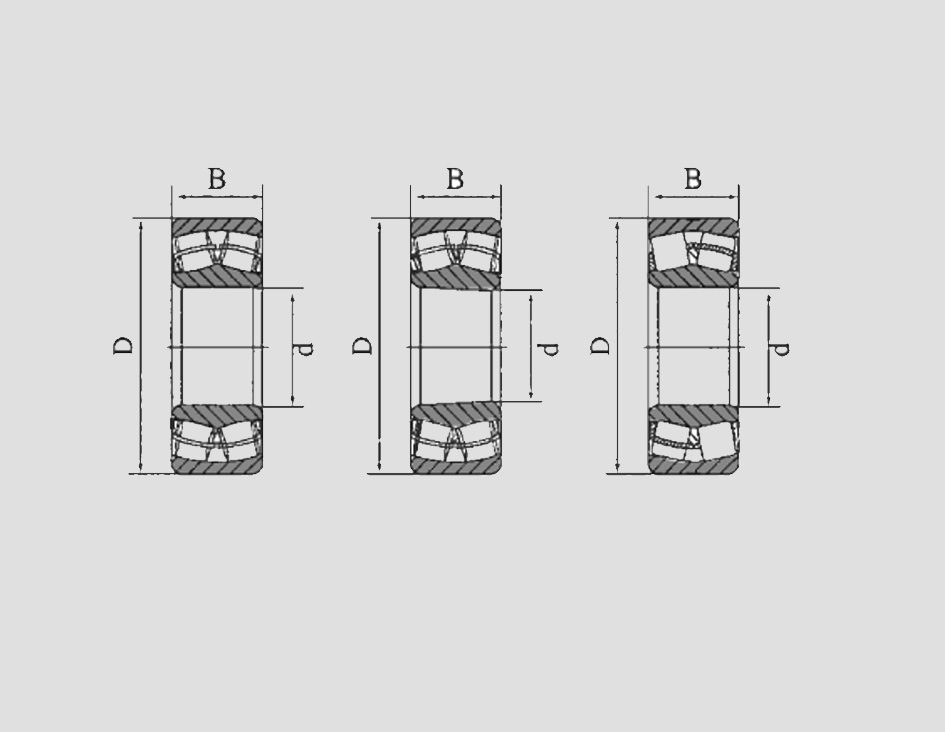

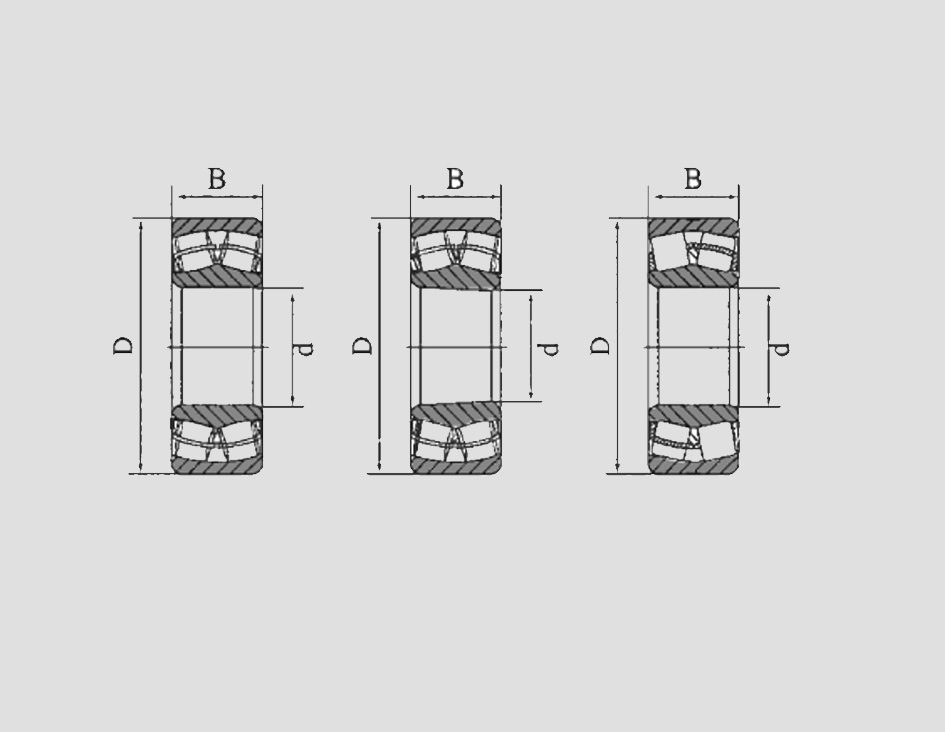

Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements single deep groove ball bearing. Width The width of the bearing, also known as the radial internal clearance, refers to the distance between the inner and outer rings. It is measured in millimeters and is typically specified as an integer value. The width can affect the bearing's load capacity and stiffness. One of the key features of the 6203Z bearing is its high-quality steel construction. This material is known for its strength, durability, and resistance to wear and tear. The steel used in the 6203Z bearing is carefully selected and processed to ensure that it meets the highest standards of quality and performance. Customers can rely on the information provided in the catalogue to select the appropriate bearing for their specific application. Key specifications such as bore diameter, outside diameter, width, load rating, and speed rating are clearly listed for each bearing, allowing for easy comparison and selection.

single deep groove ball bearing. Width The width of the bearing, also known as the radial internal clearance, refers to the distance between the inner and outer rings. It is measured in millimeters and is typically specified as an integer value. The width can affect the bearing's load capacity and stiffness. One of the key features of the 6203Z bearing is its high-quality steel construction. This material is known for its strength, durability, and resistance to wear and tear. The steel used in the 6203Z bearing is carefully selected and processed to ensure that it meets the highest standards of quality and performance. Customers can rely on the information provided in the catalogue to select the appropriate bearing for their specific application. Key specifications such as bore diameter, outside diameter, width, load rating, and speed rating are clearly listed for each bearing, allowing for easy comparison and selection. One of the key advantages of four-row taper roller bearings is their ability to support both radial and axial loads simultaneously. This dual capability makes them ideal for applications where both types of forces are present, such as gearboxes, wind turbines, and heavy equipment. Traditional bearings, on the other hand, are typically limited to supporting either radial or axial loads, which can lead to premature failure in complex operating environments.

It's important to note that the specific steps for using an angular contact bearing may vary depending on the application, the bearing's design, and the manufacturer's recommendations. Always refer to the bearing manufacturer's instructions and guidelines for the proper use and maintenance of angular contact bearings.

Understanding Axial Angular Contact Ball Bearings A Comprehensive Overview Specifications of Ball Bearing 6004 2RS The Modern Era Advanced Bearings for High-Performance Applications 4 In conclusion, inch tapered roller bearings are a critical component in many industrial and heavy-duty applications due to their ability to handle significant loads and their resilience to misalignment. Their robust design and versatility make them an essential part of ensuring the reliability and longevity of machinery operating under demanding conditions. Proper maintenance and care are necessary to harness their full potential and minimize downtime caused by bearing failures. The Significance of the 6005 2RS Bearing in Modern Industry There are several types of ball thrust bearings available on the market, each with its own unique characteristics and applications. Some of the most common types include single-direction ball thrust bearings, double-direction ball thrust bearings, and four-point contact ball thrust bearings. One of the key features of the 22211 k bearing is its ability to withstand high loads and speeds while maintaining low friction levels. This makes it an ideal choice for applications such as pumps, fans, and conveyors, where efficiency and reliability are critical. In conclusion, the 48548 10 bearing stands as a testament to the power of engineering innovation. Its ability to withstand extreme conditions, deliver high performance, and ensure precision movement underscores its importance in today's fast-paced industrial landscape. As technology continues to evolve, so will the design and capabilities of bearings like the 48548 10 , shaping the future of mechanical systems and driving progress forward. 6216 Bearing Dimensions A Comprehensive Guide Another important aspect of taper roller bearing assemblies is their ability to accommodate high radial and axial loads. This makes them suitable for heavy-duty applications where there is a need for strong and reliable support for rotary motion. The assembly can withstand high levels of stress and pressure, making it ideal for use in demanding industrial settings.

In conclusion, inch tapered roller bearings are a critical component in many industrial and heavy-duty applications due to their ability to handle significant loads and their resilience to misalignment. Their robust design and versatility make them an essential part of ensuring the reliability and longevity of machinery operating under demanding conditions. Proper maintenance and care are necessary to harness their full potential and minimize downtime caused by bearing failures. The Significance of the 6005 2RS Bearing in Modern Industry There are several types of ball thrust bearings available on the market, each with its own unique characteristics and applications. Some of the most common types include single-direction ball thrust bearings, double-direction ball thrust bearings, and four-point contact ball thrust bearings. One of the key features of the 22211 k bearing is its ability to withstand high loads and speeds while maintaining low friction levels. This makes it an ideal choice for applications such as pumps, fans, and conveyors, where efficiency and reliability are critical. In conclusion, the 48548 10 bearing stands as a testament to the power of engineering innovation. Its ability to withstand extreme conditions, deliver high performance, and ensure precision movement underscores its importance in today's fast-paced industrial landscape. As technology continues to evolve, so will the design and capabilities of bearings like the 48548 10 , shaping the future of mechanical systems and driving progress forward. 6216 Bearing Dimensions A Comprehensive Guide Another important aspect of taper roller bearing assemblies is their ability to accommodate high radial and axial loads. This makes them suitable for heavy-duty applications where there is a need for strong and reliable support for rotary motion. The assembly can withstand high levels of stress and pressure, making it ideal for use in demanding industrial settings.  lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems. The 61908 bearing, classified as a deep groove ball bearing, is a standard part in numerous industrial applications. Its dimensions, with an inner diameter of 40mm, outer diameter of 68mm, and a width of 15mm, make it suitable for compact and high-speed machinery. This particular size and design enable it to handle both radial and axial loads, contributing to its versatility in various industries. For instance, a common size might be a 130x200x51mm tapered roller bearing, where 130mm represents the bore diameter, 200mm denotes the outer diameter, and 51mm indicates the width or thickness of the bearing. The size not only determines the physical dimensions but also impacts the bearing's load-carrying capabilities and speed ratings. In addition to its load-carrying capacity, the 30232 bearing also offers high speed capabilities

lm67010 bearing. This means that it requires less energy to rotate, resulting in increased efficiency and reduced wear on the bearing itself. This is especially beneficial in applications where energy consumption is a critical factor, such as in wind turbines or other renewable energy systems. The 61908 bearing, classified as a deep groove ball bearing, is a standard part in numerous industrial applications. Its dimensions, with an inner diameter of 40mm, outer diameter of 68mm, and a width of 15mm, make it suitable for compact and high-speed machinery. This particular size and design enable it to handle both radial and axial loads, contributing to its versatility in various industries. For instance, a common size might be a 130x200x51mm tapered roller bearing, where 130mm represents the bore diameter, 200mm denotes the outer diameter, and 51mm indicates the width or thickness of the bearing. The size not only determines the physical dimensions but also impacts the bearing's load-carrying capabilities and speed ratings. In addition to its load-carrying capacity, the 30232 bearing also offers high speed capabilities

30232 bearing. This allows for efficient operation of machinery and equipment, increasing productivity and reducing downtime. The precision engineering of the bearing ensures smooth rotation and minimal vibration, further enhancing performance. Another significant advantage of this bearing is its corrosion resistance. The chrome steel construction provides excellent protection against rust and corrosion, ensuring reliable performance in harsh environments. This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment

This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment

This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment This makes it a popular choice for applications such as food processing, chemical handling, and marine equipment 6201 2z bearing dimensions. * Lubrication Applying the appropriate amount of lubricant can reduce friction and wear, extending the life of the bearing. Another important feature of these bearings is their self-aligning capability

6201 2z bearing dimensions. * Lubrication Applying the appropriate amount of lubricant can reduce friction and wear, extending the life of the bearing. Another important feature of these bearings is their self-aligning capability